In the future, honey bottle labeling machines will evolve from simple applicators into intelligent, integrated hubs at the center of production. They will become critical tools for managing data, ensuring compliance, and enhancing brand communication, far exceeding their current role of merely applying labels at high speed. This shift is driven by advancements in automation, data connectivity, and machine vision.

The core takeaway is this: investing in a labeling machine is no longer just about improving speed. The future value lies in selecting a system that can act as an intelligent node on your production line, providing the data, flexibility, and quality control needed to compete effectively.

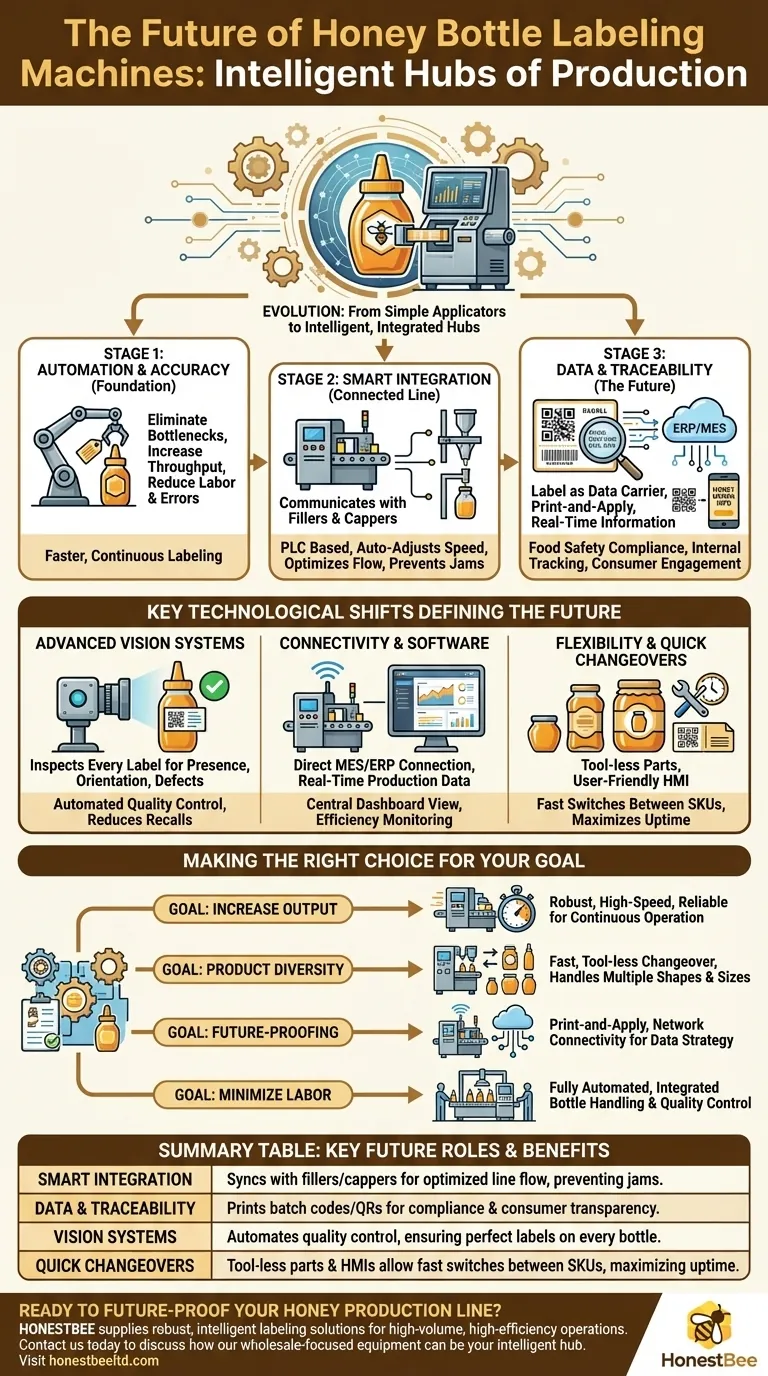

From Simple Applicators to Intelligent Systems

The fundamental purpose of a labeling machine is to improve efficiency. However, the definition of "efficiency" is expanding. It's no longer just about speed, but about intelligence, data, and adaptability.

The Foundation: Automation and Accuracy

At their core, labeling machines eliminate the bottlenecks of manual work. They enable automatic, continuous labeling that is significantly faster and more consistent than human hands.

This core function directly addresses primary production challenges by increasing throughput, reducing repetitive labor costs, and minimizing the placement errors that can damage brand perception.

The Next Step: Smart Integration

Future-ready labelers are not standalone units. They are designed to communicate with other equipment on the production line, such as fillers and cappers.

Using PLC (Programmable Logic Controller) based systems, a smart labeler can automatically adjust its speed to match the line's flow, preventing jams and optimizing the entire process from start to finish.

The Future: Data and Traceability

The label is evolving into a data carrier. Modern machines incorporate print-and-apply systems that can print unique information like batch codes, production dates, and QR codes onto each label in real-time.

This capability is no longer a luxury; it is essential for food safety regulations, internal tracking, and consumer engagement. A QR code can link a customer directly to information about the honey's origin, reinforcing brand transparency and trust.

Key Technological Shifts Defining the Future

Several specific technologies are driving this evolution. Understanding them is key to making a wise investment.

Advanced Vision Systems

Integrated cameras and sensors are becoming standard. These vision systems inspect each bottle to confirm the label is present, correctly oriented, and free of defects like wrinkles or tears.

This automates quality control, ensuring that only perfectly labeled products reach the market and reducing the risk of costly recalls or returns.

Connectivity with Factory Management Software

The most advanced machines can connect directly to a factory's Manufacturing Execution System (MES) or Enterprise Resource Planning (ERP) software.

This integration allows the labeler to send real-time production data—such as total units labeled, run time, and downtime—directly to a central dashboard. This provides management with a clear, accurate view of production efficiency.

Flexibility and Quick Changeovers

Honey producers often have multiple product SKUs with different jar shapes and label sizes. Modern machines are designed for this reality.

Look for features like tool-less changeover parts and user-friendly touchscreen interfaces (HMI). These allow operators to quickly and easily switch the machine's setup from one product to another in minutes, not hours, maximizing uptime.

Understanding the Trade-offs and Challenges

While the benefits are clear, adopting advanced labeling technology requires a realistic assessment of the challenges.

The Upfront Capital Investment

Intelligent, automated labeling systems represent a significant capital expense compared to manual labor or semi-automatic devices. The return on investment must be carefully calculated based on labor savings, increased throughput, and error reduction.

The Need for Skilled Operation and Maintenance

As machines become more complex and integrated, they require a higher level of technical skill to operate and maintain. Your team will need proper training to manage software, diagnose sensor issues, and perform routine maintenance.

Over-engineering for Your Scale

A small-batch, artisanal honey producer does not need the same system as a large-scale industrial packer. It is crucial to match the technology to your actual production volume and strategic goals to avoid paying for features you will never use.

Making the Right Choice for Your Goal

The "best" machine depends entirely on your primary business objective.

- If your primary focus is increasing output: Prioritize a robust machine with a high label-per-minute rating and proven reliability for continuous, high-speed operation.

- If your primary focus is product diversity: Seek a machine with fast, tool-less changeover capabilities to handle various bottle shapes and label dimensions with minimal downtime.

- If your primary focus is future-proofing and traceability: Invest in a system with print-and-apply functions and network connectivity to integrate with your broader data management strategy.

- If your primary focus is minimizing labor dependency: A fully automated, integrated system that manages bottle handling and quality control is the most effective long-term solution.

Ultimately, choosing the right honey bottle labeling machine is a strategic investment in your production's future efficiency, compliance, and brand integrity.

Summary Table:

| Key Feature | Future Role & Benefit |

|---|---|

| Smart Integration | Syncs with fillers/cappers for optimized line flow, preventing jams. |

| Data & Traceability | Prints batch codes/QRs for compliance and consumer transparency. |

| Vision Systems | Automates quality control, ensuring perfect labels on every bottle. |

| Quick Changeovers | Tool-less parts & HMIs allow fast switches between SKUs, maximizing uptime. |

Ready to future-proof your honey production line?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with robust, intelligent labeling solutions designed for high-volume, high-efficiency operations. Our machines are built to enhance your throughput, ensure compliance, and protect your brand integrity.

Contact HONESTBEE today to discuss how our wholesale-focused labeling equipment can become the intelligent hub of your production process.

Visual Guide

Related Products

- Automatic In-Line Flat Surface Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- What are the primary functions of professional product labels for stingless bee honey? Drive Growth and Market Trust

- How do automated labeling systems contribute to building consumer trust for honey producers? Gain Brand Credibility

- What factors should be considered when designing the size and shape of a honey label? Optimize Your Packaging Design

- Why is it essential to integrate a high-performance automatic labeling system? Secure Trust and Compliance in Honey

- What key functions do high-quality packaging materials serve? Unlock the Commercial Potential of Your Honey

- Why are traceability labels and identification systems critical components of organic honey? Ensure Quality & Trust

- How does container shape influence the efficiency of the honey labeling process? Choose the Best Jar for Automation

- Why are packaging design and detailed labeling information considered essential for the market access of honey?