The primary efficiency benefits of an automatic labeling machine are a dramatic increase in speed, unwavering consistency, and a significant reduction in errors. These machines can apply thousands of labels per hour, far surpassing manual capabilities and ensuring every product is labeled to the exact same standard without human intervention.

While often purchased for speed, the true efficiency of an automatic labeling machine comes from its ability to transform a variable, error-prone manual process into a reliable, consistent, and scalable part of your production line.

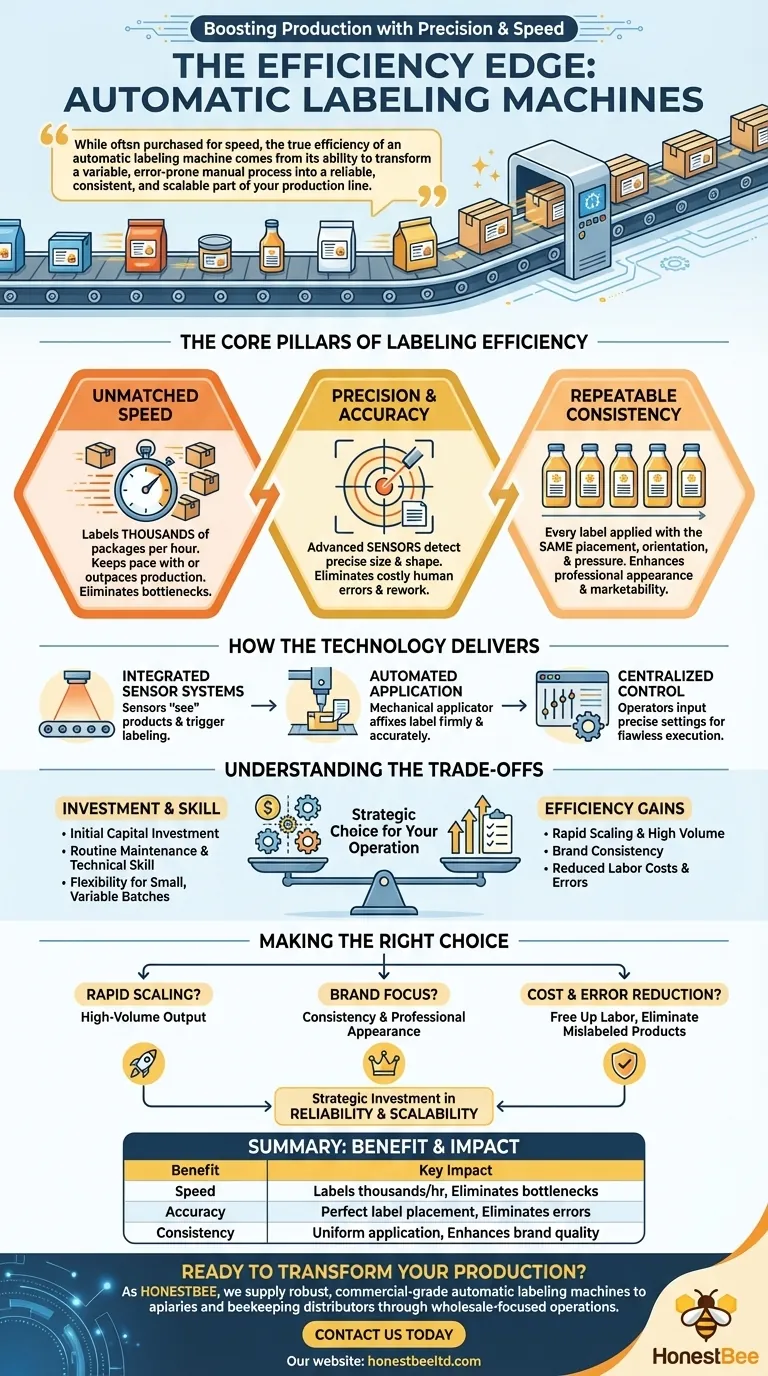

The Core Pillars of Labeling Efficiency

An automatic labeling machine's value is built on three fundamental improvements over manual or semi-automatic methods. Understanding these pillars clarifies the machine's direct impact on your operational output.

Unmatched Labeling Speed

The most obvious benefit is the sheer velocity of the operation. Automatic machines are designed for continuous, high-speed throughput.

They can label thousands of packages per hour, enabling a significant increase in overall production efficiency. This allows your labeling process to keep pace with, or even outpace, other parts of your production line.

Precision and Accuracy

Human error is a natural variable in any manual process. Automatic labelers remove this variable entirely.

Advanced sensors and control systems detect the precise size, shape, and position of each package. The machine then applies the label to the exact pre-set location every single time, eliminating costly mistakes and rework.

Repeatable Consistency

For brand perception and quality control, consistency is paramount. An automatic machine ensures every single label is applied with the same placement, orientation, and pressure.

This uniformity enhances the product's professional appearance and marketability, reinforcing brand quality in the mind of the consumer.

How the Technology Delivers These Gains

The efficiency benefits are not magic; they are the result of precise engineering and integrated systems working in concert.

Integrated Sensor Systems

Modern labeling machines use sophisticated sensors to "see" the products on the conveyor belt. These sensors identify the package's arrival and positioning, triggering the labeling action at the perfect moment.

Automated Mechanical Application

Once a product is detected, the machine automatically dispenses a single label from a roll. A mechanical applicator, such as a tamping pad or a wipe-on roller, then affixes the label firmly and accurately to the product surface without any human touch.

Centralized Control Systems

All of these actions are governed by a central control system. Operators use this system to input precise settings for label placement, which the machine then executes flawlessly for thousands of units.

Understanding the Trade-offs

While highly efficient, automatic labeling machines are not the right solution for every scenario. A clear-eyed view of the trade-offs is essential.

Initial Capital Investment

The primary barrier is the upfront cost. These machines represent a significant capital investment compared to manual labor or semi-automatic devices.

Maintenance and Technical Skill

An automatic machine requires routine maintenance and may need technical expertise to troubleshoot issues. This introduces a different kind of operational overhead compared to a manual process.

Flexibility for Small Batches

For operations that run very small, highly variable batches of different products, the setup and changeover time for an automatic machine can sometimes negate its speed advantage over a flexible manual process.

Making the Right Choice for Your Operation

The decision to invest in an automatic labeling machine should be directly tied to your specific business goals.

- If your primary focus is rapid scaling and high-volume output: The machine is a non-negotiable tool for eliminating a critical production bottleneck.

- If your primary focus is brand consistency and professional appearance: The machine's precision provides a level of uniformity that manual labeling can never consistently achieve.

- If your primary focus is reducing labor costs and eliminating errors: Automation frees up human workers for higher-value tasks and removes the financial drain of mislabeled products.

Ultimately, adopting an automatic labeling machine is a strategic investment in the reliability and scalability of your entire production process.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Speed | Labels thousands of products per hour, eliminating bottlenecks. |

| Accuracy | Advanced sensors ensure perfect label placement, eliminating errors. |

| Consistency | Every label is applied uniformly, enhancing brand quality. |

Ready to transform your production line with reliable, high-speed labeling?

As HONESTBEE, we supply robust, commercial-grade automatic labeling machines and equipment to apiaries and beekeeping distributors through wholesale-focused operations. Our solutions are designed to handle high volumes with precision, ensuring your products are consistently and professionally labeled.

Contact us today to discuss how our labeling equipment can enhance your operational efficiency and brand consistency.

Visual Guide

Related Products

- Automatic In-Line Flat Surface Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Queen Bee Catcher Plastic Bee Marker Bottle with Piston Marking Tube

People Also Ask

- How do personalized traceability labels and specialized packaging designs contribute to the marketing of urban honey?

- How do high-precision labeling and coding machines influence honey consumer trust? Build Brand Integrity and Value

- What information should be included on labels when selling local honey? A Guide to Compliance and Branding

- How do professional packaging designs and labeling materials affect the marketing of honey products? Boost brand value!

- What role do high-precision automatic labeling machines play? Elevate Your Honey Brand Reputation & Premium Value

- How can using a honey bottle labeling machine reduce labor costs? Boost ROI with Automated Precision

- What are the requirements for automatic labeling machines in honey production? Meet Standards for Nutrition & Traceability

- What role do anti-counterfeiting tracking labels play in honey packaging? Secure Your Brand Integrity