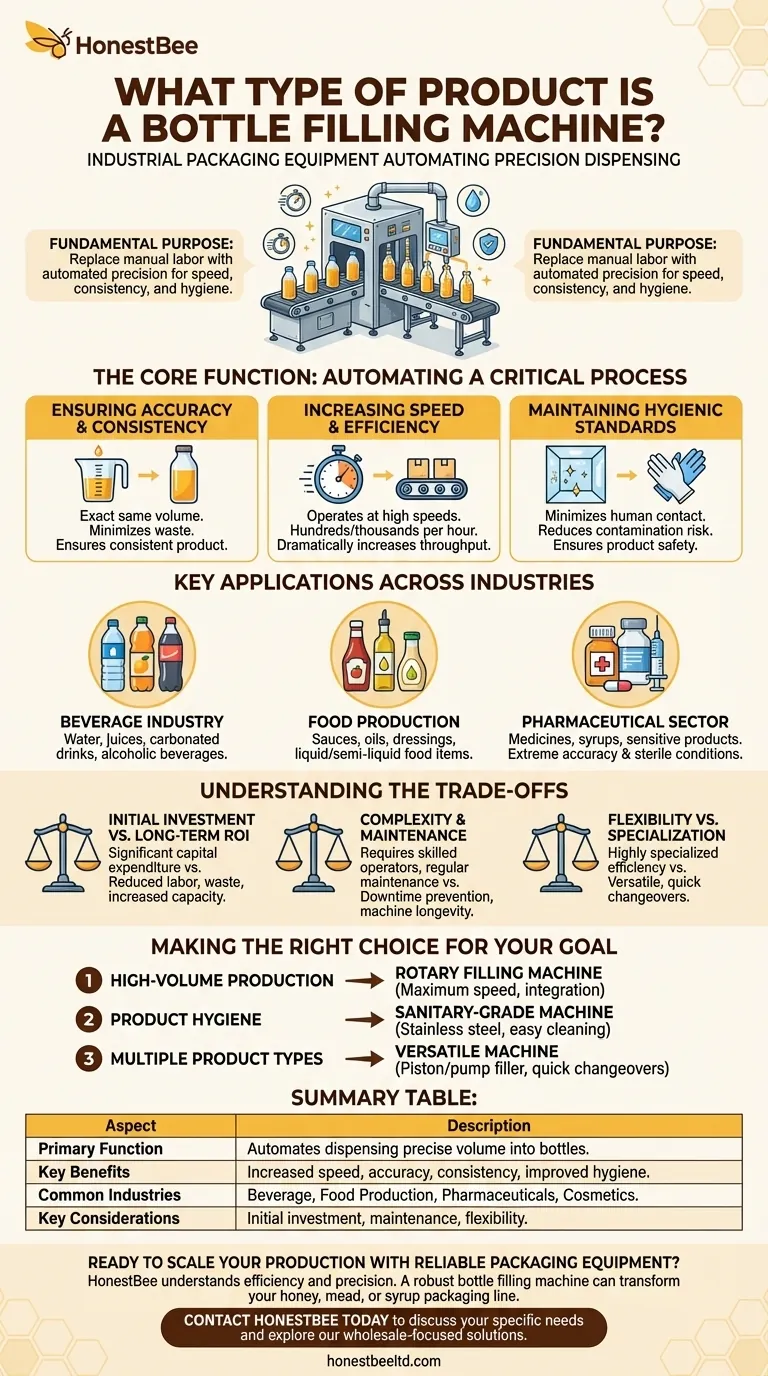

A bottle filling machine is a type of industrial packaging equipment designed to automate the process of dispensing a specific quantity of a product into bottles. It serves as a critical component in production lines, handling a wide range of substances from liquids like water and beverages to semi-liquids like sauces and even solids.

The fundamental purpose of a bottle filling machine is to replace manual labor with automated precision, enabling businesses to achieve high levels of speed, consistency, and hygiene in their packaging process.

The Core Function: Automating a Critical Process

A bottle filling machine is more than just a dispenser; it's a solution to the core challenges of packaging at scale. Its primary function is to create a repeatable and reliable filling process that is otherwise difficult for humans to achieve.

Ensuring Accuracy and Consistency

Every bottle is filled with the exact same volume of product. This precision minimizes product waste and ensures customers receive a consistent product, which is crucial for brand reputation and regulatory compliance.

Increasing Speed and Efficiency

These machines operate at speeds far beyond human capability, filling hundreds or even thousands of bottles per hour. This dramatic increase in throughput is essential for meeting market demand and scaling production.

Maintaining Hygienic Standards

In industries like food, beverage, and pharmaceuticals, hygiene is non-negotiable. Automated filling minimizes human contact with the product, reducing the risk of contamination and ensuring the final product is safe for consumption.

Key Applications Across Industries

The versatility of bottle filling machines allows them to be used in nearly every industry that packages products in bottles. The machine's design is often adapted to handle the specific properties of the product being filled.

The Beverage Industry

This is one of the most common applications. Machines fill everything from water and juices to carbonated soft drinks and alcoholic beverages, often integrated into a complete bottling and capping line.

Food Production

For food products, these machines handle a variety of viscosities. They are used to bottle sauces, oils, dressings, and other liquid or semi-liquid food items efficiently and cleanly.

The Pharmaceutical Sector

Precision and sterility are paramount in this field. Pharmaceutical fillers are designed to handle medicines, syrups, and other sensitive products with extreme accuracy and under strict sterile conditions.

Understanding the Trade-offs

While highly beneficial, integrating a bottle filling machine is a significant decision that involves balancing costs against long-term gains.

Initial Investment vs. Long-Term ROI

These machines represent a significant capital expenditure. The cost must be weighed against the long-term return on investment (ROI) from reduced labor costs, minimized product waste, and increased production capacity.

Complexity and Maintenance

Automated systems require skilled operators and regular maintenance to function correctly. Businesses must be prepared for the technical upkeep needed to prevent downtime and ensure the machine's longevity.

Flexibility vs. Specialization

Some machines are highly specialized for one type of bottle and product, offering maximum efficiency. Others are more flexible but may require more time for changeovers between different products, introducing a trade-off between specialization and versatility.

Making the Right Choice for Your Goal

Selecting the right machine depends entirely on the specific needs of your production process.

- If your primary focus is high-volume production: Prioritize a rotary filling machine designed for maximum speed and integration with a larger automated line.

- If your primary focus is product hygiene: You need a machine built with sanitary-grade materials, like stainless steel, and designed for easy cleaning, common in pharmaceutical and dairy applications.

- If your primary focus is handling multiple product types: Look for a versatile and easily adjustable machine, such as a piston or pump filler, that can handle different viscosities and allow for quick changeovers.

Ultimately, a bottle filling machine is a cornerstone technology that enables modern, large-scale production across countless industries.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | Automates the dispensing of a precise volume of product into bottles. |

| Key Benefits | Increased speed, accuracy, consistency, and improved hygiene standards. |

| Common Industries | Beverage, Food Production, Pharmaceuticals, Cosmetics. |

| Key Considerations | Initial investment, required maintenance, and flexibility for different products. |

Ready to Scale Your Production with Reliable Packaging Equipment?

As a leading supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE understands the critical need for efficiency and precision in high-volume operations. A robust bottle filling machine can transform your honey, mead, or syrup packaging line, ensuring every bottle is filled accurately and hygienically.

Let us help you find the right equipment to boost your throughput and protect your product quality. Contact HONESTBEE today to discuss your specific needs and explore our wholesale-focused solutions.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- What is the main goal of the filling machine process? Ensure Precision & Integrity for Your Products

- How does a jar or bottle packing machine function? Automate Your Packaging Line for Precision and Speed

- What role does a high-precision honey-filling machine play in GI certified honey? Ensuring Standardized Excellence

- How is automated honey filling equipment integrated with foraging prediction models? Optimize Commercial Bee Processing

- Why is the adoption of modern honey filling equipment necessary? Boost Market Competitiveness & Brand Value

- What is the function of honey extraction and filling machinery in nomadic beekeeping? Optimize Your Processing Hub

- How do automatic honey-filling machines ensure market competitiveness? Elevate Your Brand and Profitability

- How do automated honey filling and packaging machines affect profitability? Boost Margins with HONESTBEE Technology