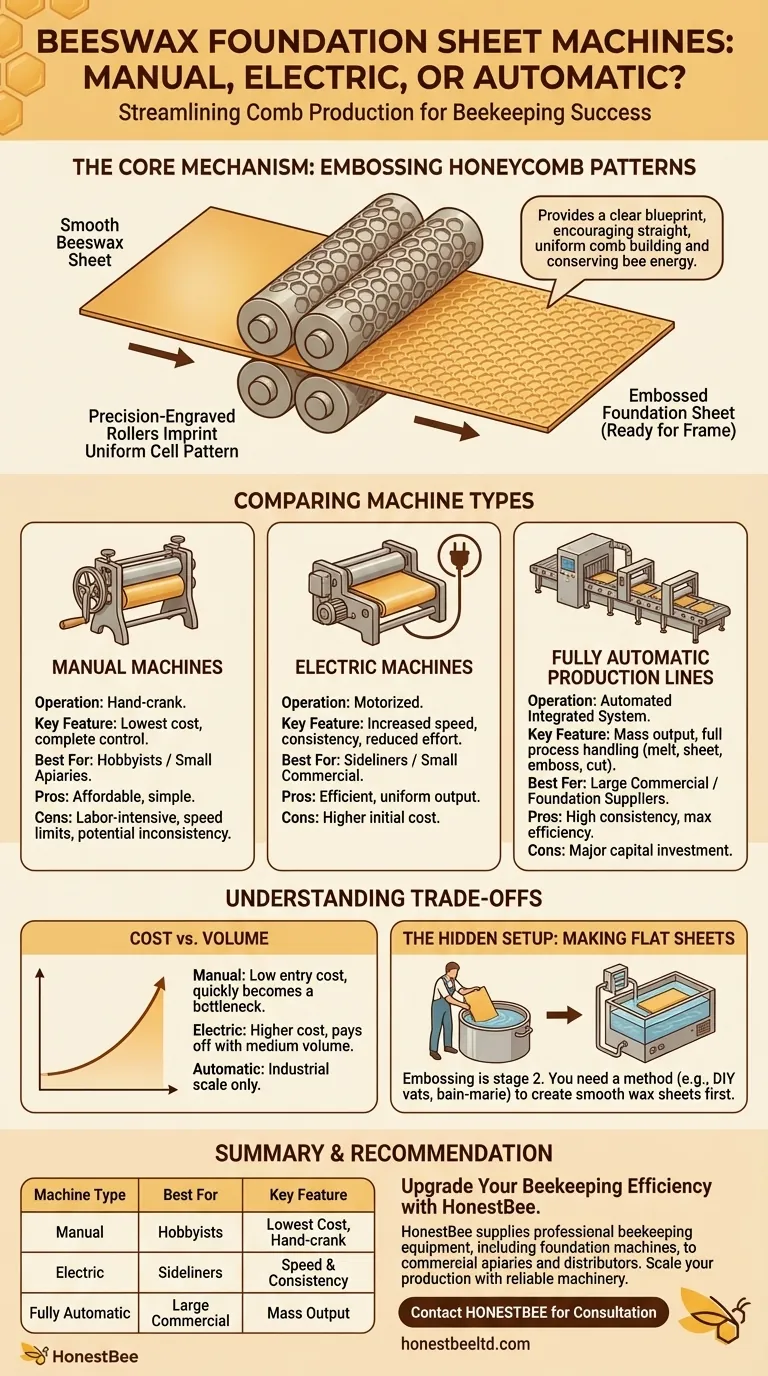

In short, beeswax foundation sheet machines are categorized into three primary types: manual, electric, and fully automatic. These machines are designed to emboss a precise honeycomb pattern onto a flat sheet of beeswax, providing a guide for your bees to build comb efficiently. The choice among them depends entirely on the scale of your beekeeping operation and your production goals.

The core decision isn't just about choosing a machine, but about understanding the entire process. Creating foundation involves two key stages: first, making smooth wax sheets, and second, embossing them with a cell pattern. Your choice of machine relates to the embossing stage, but you must also plan for the first.

The Role of a Foundation Machine

A beeswax foundation machine is a specialized piece of equipment that streamlines comb production for bees. Its primary function is to imprint a uniform cell pattern onto sheets of pure beeswax.

What is the Core Mechanism?

At its heart, the machine consists of two precision-engraved rollers mounted in a sturdy frame. The surface of these rollers has the negative pattern of honeycomb cells.

When a smooth, pre-warmed sheet of beeswax is passed between the rollers, the pattern is embossed onto both sides. This creates the "foundation" sheet that is then placed into a hive frame.

Why is This Foundation Necessary?

These embossed sheets give the honeybee colony a clear blueprint. It encourages them to build straight, uniform combs within the frame, which drastically simplifies hive inspections and honey extraction.

By providing this base, you help the bees conserve energy they would otherwise spend creating the initial structure from scratch. This can lead to healthier colonies and more efficient honey production.

Comparing the Machine Types

The right machine for you is determined by your production volume, budget, and how much manual effort you are willing to invest. The production process generally involves first creating a flat wax sheet (often a DIY setup using vats or water baths) and then running it through one of these machines.

Manual Machines

Manual machines are operated with a hand crank. The user feeds a warmed wax sheet into the rollers and turns the crank to emboss it.

This option is best suited for hobbyist beekeepers with a small number of hives. It offers the lowest initial cost and gives you complete control over the speed and process, but it is the most labor-intensive.

Electric Machines

Electric machines replace the hand crank with a motor. This automates the rolling process, significantly increasing speed and reducing the physical effort required.

These are ideal for "sideliners" or small commercial beekeepers who need to produce foundation for dozens or even hundreds of hives. The machine ensures a consistent embossing speed, which can improve the quality and uniformity of the final sheets.

Fully Automatic Production Lines

Fully automatic systems are designed for large-scale commercial operations. These are not just single machines but integrated production lines that can handle everything from melting the wax to creating the flat sheets, embossing them, and cutting them to size.

This type represents a major capital investment and is only practical for businesses that produce and sell beeswax foundation or manage thousands of hives.

Understanding the Trade-offs

Choosing a machine involves balancing cost, efficiency, and the realities of working with beeswax.

Cost vs. Volume

A manual roller is the most accessible entry point but becomes a bottleneck as your apiary grows. An electric machine costs more upfront but quickly pays for itself in time saved if you manage more than a handful of hives. Automatic lines are purely for industrial-scale needs.

The Hidden Setup: Making the Sheets

The references highlight a critical point: the embossing machine is only one part of the equation. You must also have a method for creating the initial flat wax sheets.

Many beekeepers build their own systems for this, often using thermostat-controlled water baths (bain-marie), dipping boards, and vats to melt and form the sheets before they ever reach the embossing rollers. This "DIY factor" is a significant part of the overall process and cost.

Quality and Consistency

While a manual machine gives you tactile control, operator fatigue or inexperience can lead to inconsistent results. Electric machines provide a more uniform output due to their steady, motorized speed. Automatic lines offer the highest level of consistency for mass production.

Making the Right Choice for Your Apiary

Your goal determines the right equipment. Be realistic about the number of hives you manage and your growth plans.

- If your primary focus is a few backyard hives: A manual embossing roller, combined with a simple DIY setup for making flat sheets, offers an affordable and effective solution.

- If your primary focus is a growing sideliner business: An electric machine is a worthwhile investment to dramatically increase your efficiency and ensure consistent quality across many hives.

- If your primary focus is large-scale commercial production: A fully automatic production line is the only viable option to meet the demands of a commercial honey or foundation supply business.

Ultimately, producing your own foundation gives you complete control over the purity and quality of the wax in your hives.

Summary Table:

| Machine Type | Best For | Key Feature |

|---|---|---|

| Manual | Hobbyists / Small Apiaries | Hand-crank operation, lowest cost |

| Electric | Sideliners / Small Commercial | Motorized for speed and consistency |

| Fully Automatic | Large Commercial / Foundation Suppliers | Integrated production line for mass output |

Upgrade your beekeeping efficiency with the right foundation equipment.

HONESTBEE supplies professional beekeeping supplies and equipment, including foundation sheet machines, to commercial apiaries and beekeeping equipment distributors through our wholesale-focused operations. Let us help you scale your production with reliable, high-quality machinery.

Contact HONESTBEE today for a consultation and to find the perfect solution for your operation.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Mini Desktop Bee Hive Frame Forming Making Machine

People Also Ask

- How does the beeswax flatting and embossing machine prepare the wax for processing? Achieve Perfectly Uniform Wax Sheets

- What is the primary function of the manual honeycomb embossing machine? Gain Control Over Your Hive's Foundation

- What additional preparation is needed for the work area when making beeswax sheets? Set Up a Professional Production Line

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- Why is the precise hexagonal geometry of the rollers critical? Master Beeswax Foundation Quality for Higher Yields