The machine specifically designed for sealing bottles is known as a capping machine. This equipment is an essential component in any packaging line, responsible for applying and securing closures like screw caps or snap-on lids onto bottles, jars, and other containers. Its core function is to create a consistent and reliable seal, which is critical for product integrity, safety, and shelf life.

While the simple answer is a "capping machine," the critical decision lies in understanding which type of capper aligns with your production volume, cap design, and operational budget. The right choice directly impacts your efficiency and product quality.

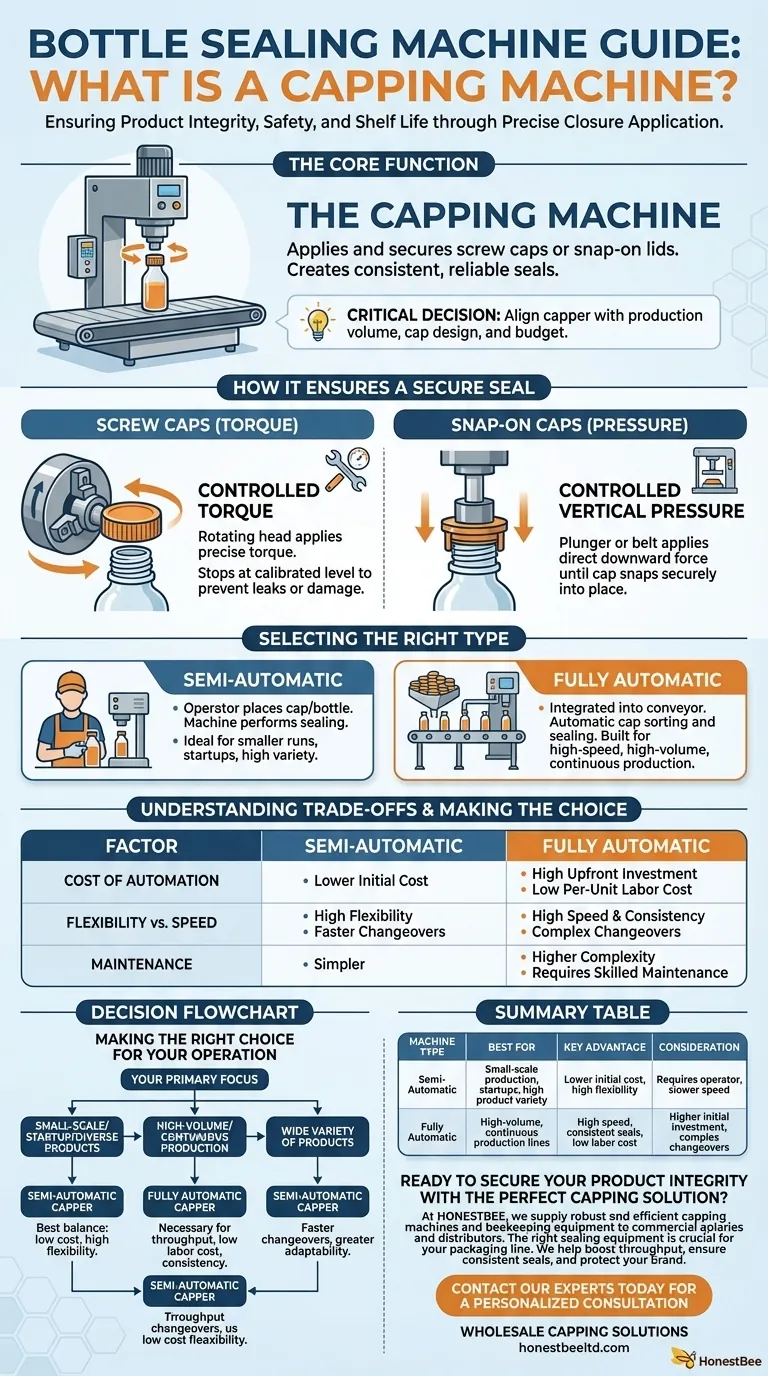

How Capping Machines Ensure a Secure Seal

A capping machine moves beyond simple manual tightening by applying precise, repeatable force. This mechanization is the key to preventing leaks, ensuring tamper-evidence, and maintaining product freshness across thousands of units.

The Principle of Operation

The machine's primary goal is to apply a cap with a consistent amount of force. For screw caps, this is achieved through controlled torque. For press-on caps, it is achieved through controlled vertical pressure. This automation removes the variability and fatigue associated with manual labor.

Handling Screw Caps

For threaded caps, the capping machine uses a rotating head (or "chuck") that grips the cap and spins it onto the bottle's threads. The machine is calibrated to stop when a specific torque level is reached, ensuring the seal is tight enough to prevent leaks but not so tight that it becomes difficult for the end-user to open or damages the cap or bottle.

Handling Snap-On Caps

For snap-on or press-on lids, the mechanism applies a direct, controlled downward force. A plunger or belt presses the cap firmly onto the container's rim until it snaps securely into place, creating an airtight seal.

Selecting the Right Type of Capping Machine

Capping machines are broadly categorized by their level of automation. The choice between them is one of the most significant decisions for a packaging line.

Semi-Automatic Capping

In a semi-automatic setup, an operator is typically required to place the cap on the bottle manually. They then place the bottle into the machine, which performs the actual tightening or pressing operation. These machines are ideal for smaller production runs, startups, or lines that handle a wide variety of bottle and cap sizes.

Fully Automatic Capping

Fully automatic cappers are integrated directly into a production conveyor system. Bottles move along the conveyor, caps are automatically sorted and placed onto the bottles, and the sealing process happens without any operator intervention. These systems are built for high-speed, high-volume, and continuous production environments.

Understanding the Trade-offs

Choosing a capping machine involves balancing cost, speed, and flexibility. Understanding these trade-offs is essential for making a sound investment.

The Cost of Automation

Fully automatic systems represent a significant upfront capital investment but drastically reduce per-unit labor costs and can run continuously. Semi-automatic machines are far less expensive to purchase but require a dedicated operator, increasing long-term labor costs.

Flexibility vs. Speed

Semi-automatic machines are generally more flexible. An operator can easily switch between different bottle heights or cap diameters with minimal downtime. Fully automatic machines are optimized for speed and consistency on a single product format; changeovers to different sizes can be more complex and time-consuming.

Maintenance and Complexity

The higher the level of automation, the greater the mechanical and electrical complexity. Fully automatic cappers require more sophisticated maintenance and troubleshooting skills compared to their simpler, semi-automatic counterparts.

Making the Right Choice for Your Operation

Base your decision on your specific operational goals and constraints.

- If your primary focus is a small-scale or startup operation: A semi-automatic capper offers the best balance of low initial cost and high flexibility for diverse or changing product needs.

- If your primary focus is high-volume, continuous production: A fully automatic capper is necessary to achieve the required throughput, minimize labor costs, and ensure maximum consistency.

- If your primary focus is handling a wide variety of products: A semi-automatic machine often provides faster changeovers and greater adaptability than a highly specialized automatic system.

Ultimately, selecting the right capping machine is a strategic decision that directly supports your operational efficiency and brand integrity.

Summary Table:

| Machine Type | Best For | Key Advantage | Consideration |

|---|---|---|---|

| Semi-Automatic | Small-scale production, startups, high product variety | Lower initial cost, high flexibility | Requires operator, slower speed |

| Fully Automatic | High-volume, continuous production lines | High speed, consistent seals, low labor cost | Higher initial investment, complex changeovers |

Ready to secure your product integrity with the perfect capping solution?

At HONESTBEE, we supply robust and efficient capping machines and beekeeping equipment to commercial apiaries and distributors. The right sealing equipment is as crucial to your packaging line as quality equipment is to a successful hive. We can help you choose a machine that boosts your throughput, ensures consistent seals, and protects your brand.

Contact our experts today for a personalized consultation on our wholesale capping solutions.

Visual Guide

Related Products

- Semi Automatic Electric Bottle Capping Machine

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Automatic Inline Spindle Bottle Capping Machine for Honey Production

- Automatic In-Line Round Bottle Labeling Machine

People Also Ask

- What are the main types of caps supported by bottle capping equipment? Threaded, Press-On, and Insertion

- What are the categories of bottle capping machines? Choose the Right Automation for Your Line

- What is the working principle of bottle packing machine? Achieve Efficient, Automated Filling

- Can you bottle honey right after extraction? Weighing Speed vs. Quality for Your Apiary

- How does a bottle capping machine work? Unlock Efficient, Consistent Sealing for Your Production Line

- What is the purpose of bottle capping equipment and what types are available? Professional Sealing Solutions

- What is the function of a capping machine in honey packaging? Secure Your Product Quality and Shelf Life

- How does a bottle machine work? Master the Automated Bottling Process