The effectiveness of a beetle blaster is entirely dependent on its lack of gaps. Any crack or crevice in the trap's body provides the Small Hive Beetle (SHB) with a safe place to hide, completely undermining the trap's purpose. Instead of being forced into the oil-filled reservoir, the beetles will simply use the defect as a sanctuary, rendering the tool useless and making your beekeeping efforts harder.

The Small Hive Beetle's core survival instinct is to seek refuge in tight cracks and corners. A properly designed, seamless beetle blaster removes all alternative hiding spots, forcing the beetles into the trap's collection chamber as their only escape route.

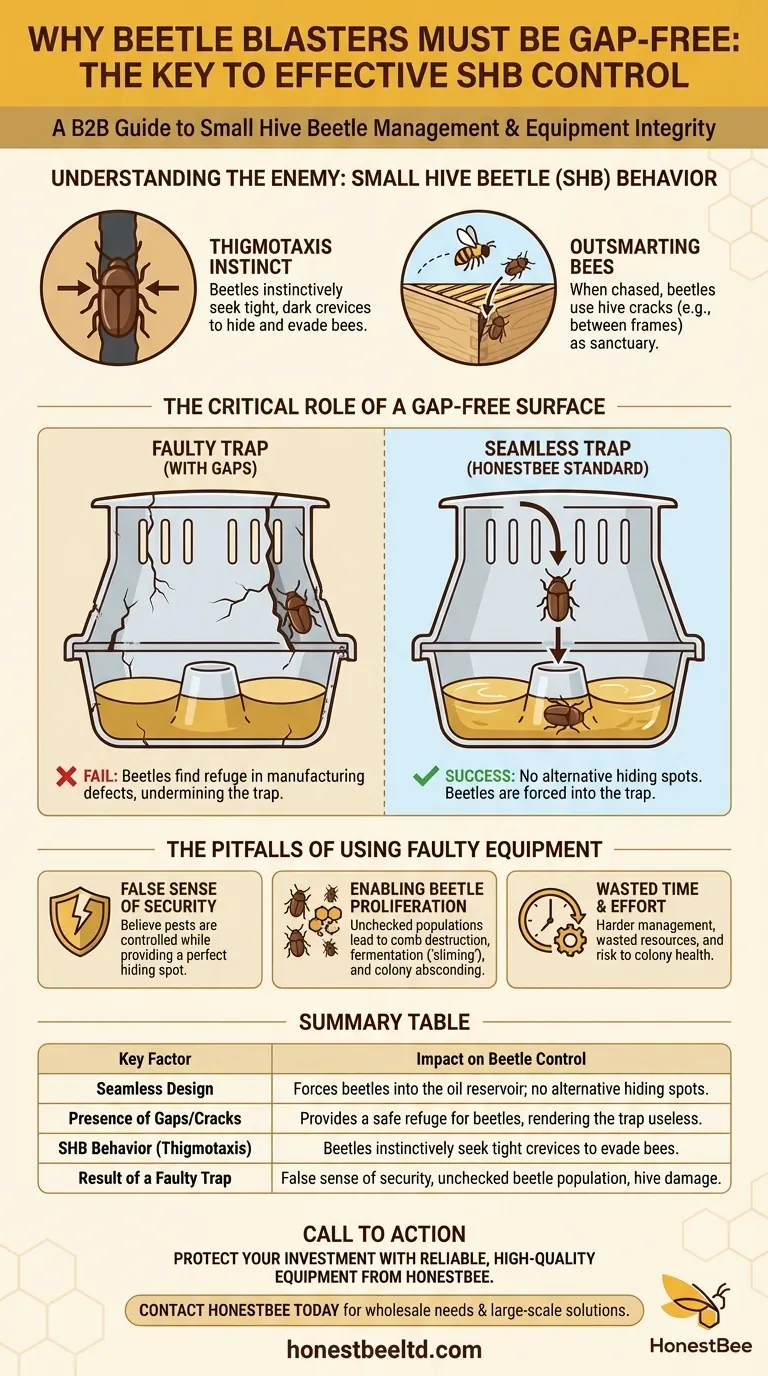

Understanding the Enemy: Small Hive Beetle Behavior

An Instinct for Cracks

The Small Hive Beetle exhibits a behavior known as thigmotaxis, meaning it is instinctively drawn to the stimulus of touch and pressure. They seek out tight, dark crevices to hide, mate, and lay eggs.

This is a survival mechanism. By wedging themselves into tiny gaps, they can effectively evade the guard bees who are trying to harass and expel them from the hive.

How They Outsmart Bees

When chased by bees, the SHB will run across the tops of the frames looking for the nearest crack to dive into. A standard hive body is full of such opportunities between frames and in the corners of the box. The beetle blaster is designed to take advantage of this exact behavior.

How a Seamless Trap Design Works

The Fundamental Principle

A beetle blaster is a simple, non-toxic trap that sits on top of the frames inside a hive body. It consists of a plastic trough with slots on top, which you fill with a small amount of vegetable oil or diatomaceous earth.

The trap works by presenting a more attractive hiding spot than other areas in the hive. Bees chase the beetles across the frames, and the beetles, seeking refuge, dive into the trap's slots.

The Critical Role of a Gap-Free Surface

This entire process fails if the trap itself has flaws. If there are manufacturing defects, hairline cracks, or gaps in the plastic body of the beetle blaster, the beetles will hide there instead of falling into the oil.

A seamless, perfectly molded trap leaves the beetle with no choice. The only "cracks" available for it to escape into are the trap's slots, which lead directly to its demise. The integrity of the trap's surface is therefore not a minor detail—it is the very key to its function.

The Pitfalls of Using Faulty Equipment

A False Sense of Security

Using a cracked or poorly made beetle blaster is worse than using no trap at all. It gives the beekeeper a false sense of security, leading them to believe they are controlling the pest population when, in fact, they are providing the beetles with a perfect hiding spot.

Enabling Beetle Proliferation

If the traps are ineffective, the SHB population can grow unchecked. This can lead to the destruction of comb, fermentation of honey (known as "sliming"), and can ultimately cause the entire bee colony to abscond, abandoning the hive.

Wasted Time and Effort

Beekeeping requires careful observation and management. Using equipment that doesn't work as intended makes the job harder, wastes resources, and puts the health of your colony at risk.

Making the Right Choice for Your Hive

A small detail like a crack in a plastic trap can have a significant impact on the health of your beehive. Paying attention to equipment quality is a fundamental part of successful pest management.

- If your primary focus is maximizing pest capture: Always inspect new beetle blasters for molding defects or cracks before placing them in the hive, and choose models known for their solid, single-piece construction.

- If your primary focus is integrated pest management: Use seamless beetle blasters as one part of a larger strategy that includes maintaining strong colonies and minimizing unnecessary gaps elsewhere in the hive equipment.

Ultimately, effective beetle control is about understanding and outsmarting the pest's natural behavior.

Summary Table:

| Key Factor | Impact on Beetle Control |

|---|---|

| Seamless Design | Forces beetles into the oil reservoir; no alternative hiding spots. |

| Presence of Gaps/Cracks | Provides a safe refuge for beetles, rendering the trap useless. |

| SHB Behavior (Thigmotaxis) | Beetles instinctively seek tight crevices to evade bees. |

| Result of a Faulty Trap | False sense of security, unchecked beetle population, hive damage. |

Protect your investment and your colonies with reliable, high-quality equipment from HONESTBEE.

Don't let faulty beetle blasters undermine your pest management efforts. We supply commercial apiaries and beekeeping equipment distributors with durable, precision-molded traps designed without gaps to ensure maximum effectiveness.

Contact HONESTBEE today to discuss your wholesale needs and discover how our equipment supports successful, large-scale beekeeping operations.

Visual Guide

Related Products

- Reusable Clear Small Hive Beetle Traps for Beehives Beetle Trapping Tools

- Reusable Aluminium Beetle Trap for Small Hive Beetles Silver Bullet

- Black Plastic Beetle Barn Hive Beetle Trap for Beehives

- Plastic Beetle Blaster Trap Beekeeping Tools and Supplies

- Removable Washable Hive Beetle Trap Attractants for Small Hive Beetles

People Also Ask

- How do hive beetle traps work? A Beekeeper's Guide to Non-Chemical Control

- What are the steps for installing hive beetle traps? A Guide to Effective Beetle Control

- What is the technical necessity of using 8-mesh hardware cloth? Optimize Small Hive Beetle Traps for Colony Safety

- What is the general guide for installing and using hive beetle traps? Maximize Your Apiary Health Today

- How do professional-grade environmental hygiene and disinfection tools assist in managing mild SHB infestations?

- Why are hive beetle traps important for beekeepers? Protect Your Hive from a Devastating Infestation

- How are handheld beetle traps used? Master Effective Hive Protection and Pest Control

- What is the recommended approach for managing small hive beetles in warm and tropical climates? Build a Strong Hive Defense