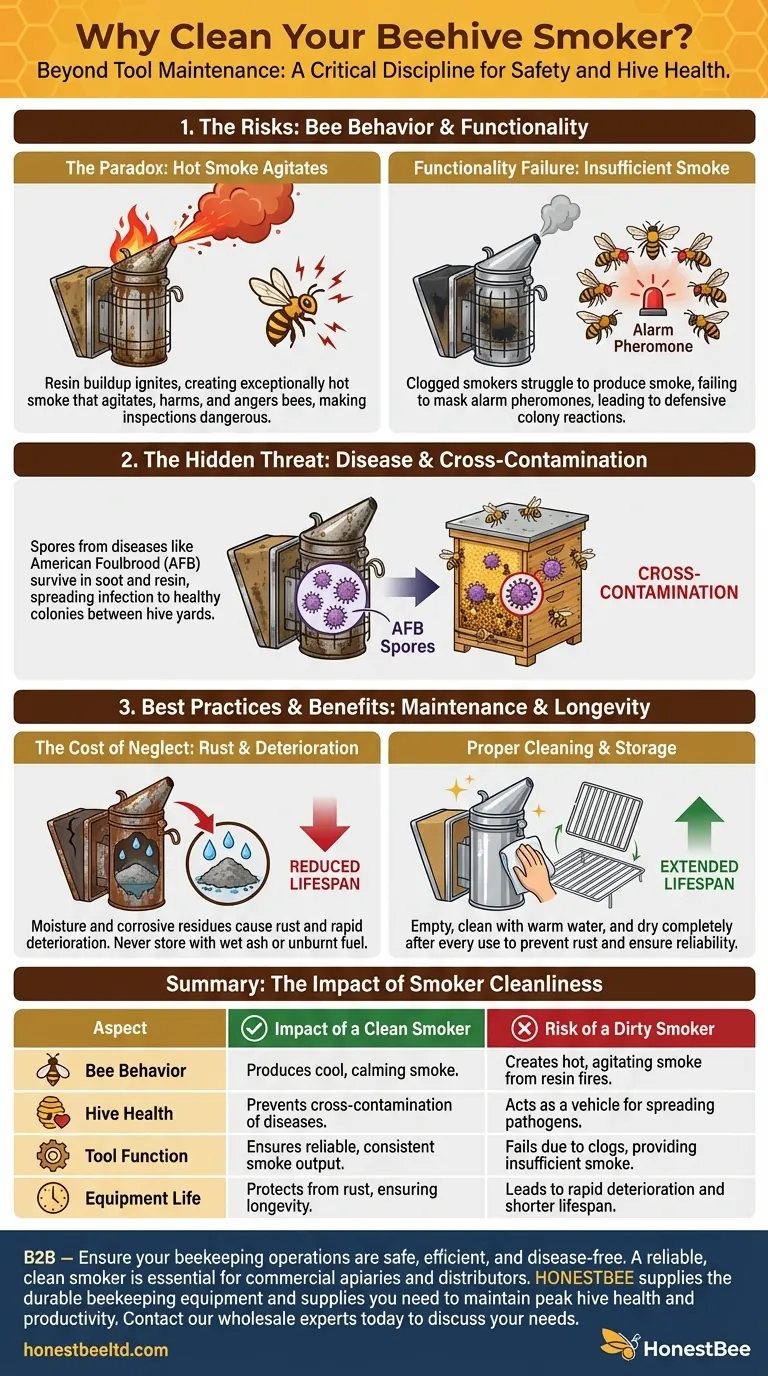

Beyond simple tool maintenance, cleaning your beehive smoker is a critical discipline that directly impacts bee behavior, hive health, and the overall safety of your inspections. A dirty smoker fails at its primary job of calming bees and can actively agitate them, while also posing a hidden risk of spreading disease between your colonies.

A clean smoker is not just about equipment longevity; it is a fundamental component of predictable and safe hive management. Proper cleaning ensures the tool calms bees as intended, rather than agitating them with hot smoke, and prevents it from becoming a vector for disease.

Why a Dirty Smoker Undermines Its Purpose

A bee smoker is your primary tool for communicating calm and control during a hive inspection. When it's dirty, it can broadcast the opposite message.

The Paradox: How a Dirty Smoker Agitates Bees

A primary reason for cleaning is to remove the buildup of creosote and resin inside the smoker's chamber and lid. This dark, sticky residue is highly flammable.

When you operate a smoker with heavy resin deposits, stray sparks can ignite this buildup. This creates a blast of exceptionally hot smoke, which does not calm bees. Instead, it harms or angers them, making your hive inspection more difficult and dangerous.

The Functionality Failure: Insufficient Smoke

The purpose of smoke is to mask the bees' natural alarm pheromones, preventing a colony-wide defensive response. It also encourages them to consume honey, which has a further calming effect.

A smoker clogged with soot, tar, and unburnt fuel cannot function correctly. The bellows will struggle to push air through the chamber, resulting in weak, inconsistent, or insufficient smoke. When you need it most, a clogged smoker will fail, leaving you unable to manage the colony's defensiveness.

The Hidden Risk: Disease and Cross-Contamination

Beyond bee behavior, a dirty smoker represents a significant biosecurity threat that is often overlooked.

Your Smoker as a Vehicle for Pathogens

Bee diseases, particularly bacterial infections like American Foulbrood (AFB), produce hardy spores that can survive for years. These spores can easily become mixed in the soot and resin inside your smoker.

If you use that contaminated smoker on a healthy hive, you are effectively inoculating that new colony with the disease. This risk of cross-contamination is why professional inspectors and responsible beekeepers sanitize tools between hive yards.

Protecting Your Investment

Maintaining hive health is the core of successful beekeeping. A single infected hive can quickly spread disease to other colonies. Regular smoker cleaning is a simple, low-cost preventative measure to protect the health of all your bees.

Best Practices and Common Pitfalls

Proper maintenance is about more than just cleaning; it involves the entire cycle of use, extinguishing, and storage.

The Cost of Neglect: Rust and Reduced Lifespan

The combination of heat, moisture from the fuel, and corrosive resins will quickly damage a smoker. Leaving wet ashes or unburnt fuel inside will cause the metal to rust and deteriorate.

Thoroughly cleaning the smoker and ensuring it is completely dry before storage is essential for protecting your investment and ensuring the tool lasts for many seasons.

The Cleaning and Extinguishing Procedure

After every use, allow the smoker to cool completely. Empty the remaining fuel and ash, being careful not to lose the grate at the bottom.

Use warm water and a soft cloth or brush to wipe away residue. For stubborn tar, a mild soap can be used. Most importantly, allow the smoker to air dry thoroughly to prevent rust.

When extinguishing, you can either tamp down the fuel and seal the lid to preserve it for next time or fully extinguish the contents in a bucket of water. Never store a smoker with smoldering fuel inside.

Applying This to Your Beekeeping Practice

Integrating smoker cleaning into your routine is a small habit that pays significant dividends in safety and hive health.

- If your primary focus is bee safety and calm inspections: Regular cleaning to prevent resin fires and hot smoke is the most important step you can take.

- If your primary focus is hive health and biosecurity: Cleaning your smoker between uses, especially when moving between different apiaries, is a non-negotiable part of your disease prevention strategy.

- If your primary focus is tool reliability and longevity: Emptying, cleaning, and drying your smoker after each use ensures it will work when you need it and protects it from rust and damage.

Mastering this simple discipline transforms your smoker from a potential liability into your most reliable beekeeping partner.

Summary Table:

| Aspect | Impact of a Clean Smoker | Risk of a Dirty Smoker |

|---|---|---|

| Bee Behavior | Produces cool, calming smoke | Creates hot, agitating smoke from resin fires |

| Hive Health | Prevents cross-contamination of diseases like AFB | Acts as a vehicle for spreading pathogens |

| Tool Function | Ensures reliable, consistent smoke output | Fails due to clogs, providing insufficient smoke |

| Equipment Life | Protects from rust and corrosion, ensuring longevity | Leads to rapid deterioration and a shorter lifespan |

Ensure your beekeeping operations are safe, efficient, and disease-free. A reliable, clean smoker is essential for commercial apiaries and distributors. HONESTBEE supplies the durable beekeeping equipment and supplies you need to maintain peak hive health and productivity. Contact our wholesale experts today to discuss your needs and discover how we can support your business.

Visual Guide

Related Products

- 54-Piece Smoker Fuel Pellets for Beekeeping Beehive Smoker Fuel

- Stainless Steel Honey Bee Smoker Hive and Honeycomb Smoker for Beekeeping

- European Stainless Steel Bee Smoker for Honey Bee Hive

- Stainless Steel Electric Beehive Smoker for Beekeeping and Bee Keeper Use

- Premium Traditional Copper Bee Smoker with Bellows

People Also Ask

- What is used in a bee smoker? Master the Best Fuels for Calm, Healthy Hives

- Which parts of a hive smoker require cleaning? Essential Maintenance for Optimal Airflow and Bee Safety

- What types of fuel are suitable for use in a bee smoker to ensure bee safety? Guide to Natural, Non-Toxic Fuel Selection

- What are two methods for safely extinguishing a bee smoker? Prevent Apiary Fires with These Pro Tips

- What is the best bee hive smoker fuel? Choose Natural, Slow-Burning Fuel for Calm Bees