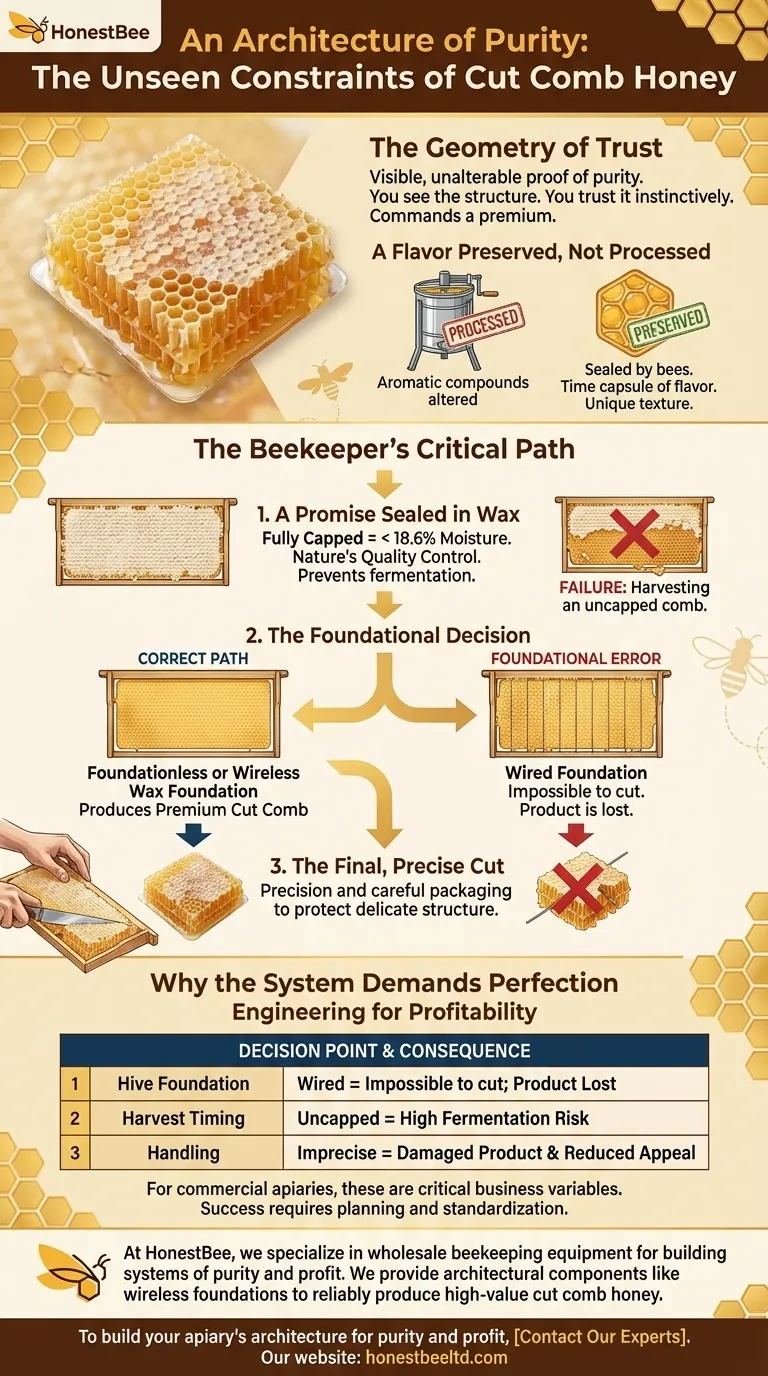

The Geometry of Trust

Imagine holding a perfect, jewel-like square of honeycomb. The golden honey is still sealed inside the pristine, hexagonal cells of beeswax where the bees placed it. This is cut comb honey.

It's more than just a food product; it's a statement. In a world of complex supply chains and processed ingredients, comb honey offers something psychologically powerful: visible, unalterable proof of purity. You see the structure the bees built. You trust it instinctively.

This is why it commands a premium. It’s not just honey; it's honey in its most honest and original architectural form.

A Flavor Preserved, Not Processed

Extracted honey is wonderful, but the process of spinning, filtering, and bottling can subtly alter its most delicate aromatic compounds.

Cut comb honey bypasses all of this. The honey is sealed by the bees, untouched by human machinery. Each cell is a time capsule of flavor from a specific nectar flow. Eating it, along with the soft, edible beeswax, is the closest one can get to experiencing honey straight from the hive. The texture is unique, the flavor profile unparalleled.

It is, in essence, the perfect natural package.

The Beekeeper's Critical Path

Producing this perfect package is not a happy accident. It is the result of deliberate engineering and foresight. A beekeeper's success or failure is often determined by a single decision made months before the honey is even ready.

A Promise Sealed in Wax

The first checkpoint is a visual one. Beekeepers look for a comb that is "fully capped." This means the bees have filled the cells and sealed them with a fresh layer of wax.

This isn't just for looks. The capping is a critical signal from the bees that the honey’s moisture content is below 18.6%. It's nature's quality control stamp, guaranteeing the honey is stable and will not ferment. Harvesting an uncapped comb is harvesting a future failure.

The Foundational Decision

Here lies the most unforgiving constraint. You can only produce cut comb honey from frames that are foundationless or use a pure, wireless wax foundation.

Imagine a commercial beekeeper in late summer, looking at a frame heavy with perfectly capped honey. The potential profit is right there. But as they go to cut it, the knife hits an obstacle: a wire. A structural support wire, embedded deep within the wax, which they installed in early spring to guide the bees.

That single, early choice has rendered this entire beautiful comb useless for cut comb production. The geometry of the final product was compromised by its initial architecture.

The Final, Precise Cut

If the foundation is correct and the comb is fully capped, the final step is an act of precision. The comb is carefully removed, laid flat, and cut into clean, uniform portions. Each piece is then packaged to protect its delicate structure, showcasing the perfect hexagonal pattern to the final customer.

Why the System Demands Perfection

The path to premium cut comb honey is a system with strict rules. Deviating from the path doesn't just create a slight imperfection; it often results in a complete loss of the intended product.

| Decision Point | The Architect's Choice | The Consequence of Error |

|---|---|---|

| Hive Foundation | Foundationless or Wireless Wax | Impossible to cut; product is lost. |

| Harvest Timing | Fully Capped Comb | High risk of fermentation and spoilage. |

| Handling | Precise tools & careful packaging | Damaged product, reduced shelf appeal. |

Engineering for Profitability

For commercial apiaries and distributors, these aren't just points of beekeeping philosophy; they are critical business variables. The "foundational error" of using wired frames isn't just a shame—it's a direct hit to the bottom line, preventing access to a high-margin product category.

Success at scale requires planning and standardization. It means deliberately building hives with the end product in mind. This involves a reliable supply of the right equipment—specifically, foundationless frames and specialized comb honey supers designed for producing clean, even combs.

At HONESTBEE, we specialize in supplying the wholesale beekeeping equipment that commercial operations need to build these systems of purity and profit. We provide the architectural components, from wireless foundations to specialized supers, that allow you to bypass the foundational error and reliably produce high-value cut comb honey.

To build your apiary's architecture for purity and profit, you need a partner who understands the foundation. Contact Our Experts

Visual Guide

Related Products

- Heavy Duty Stainless Steel Honeycomb Cutter

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Extra Wide Stainless Steel Honey Uncapping Fork with Scraper Beekeeping Tool

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

Related Articles

- How to Diagnose Queen Health and Colony Strength Through Brood Pattern Analysis

- How to Perfect Honey Moisture Levels: A Beekeeper’s Guide to Refractometer Mastery

- The Unseen Guardian: Strainer Mesh Size as a First Principle in Honey Processing

- How Comb Architecture Dictates Hive Productivity: A Beekeeper's Guide

- How to Harvest Honeycombs Efficiently Without Compromising Quality or Bee Health