The Moment of Failure

An industrial honey pump isn't loud, but its silence is deafening. One moment, it's humming along, moving hundreds of gallons of warm, liquid gold. The next, a strained groan, a shudder, and then—nothing. The entire processing line grinds to a halt.

The culprit is often microscopic. A single piece of beeswax, a stray pollen granule, or a shard of propolis, just slightly too large, has found its way into a tight tolerance. It’s a failure not of the pump, but of a component that costs a tiny fraction of its price: the strainer.

This scenario isn't just a mechanical problem; it's a systems problem. And its prevention begins with understanding a single, fundamental principle.

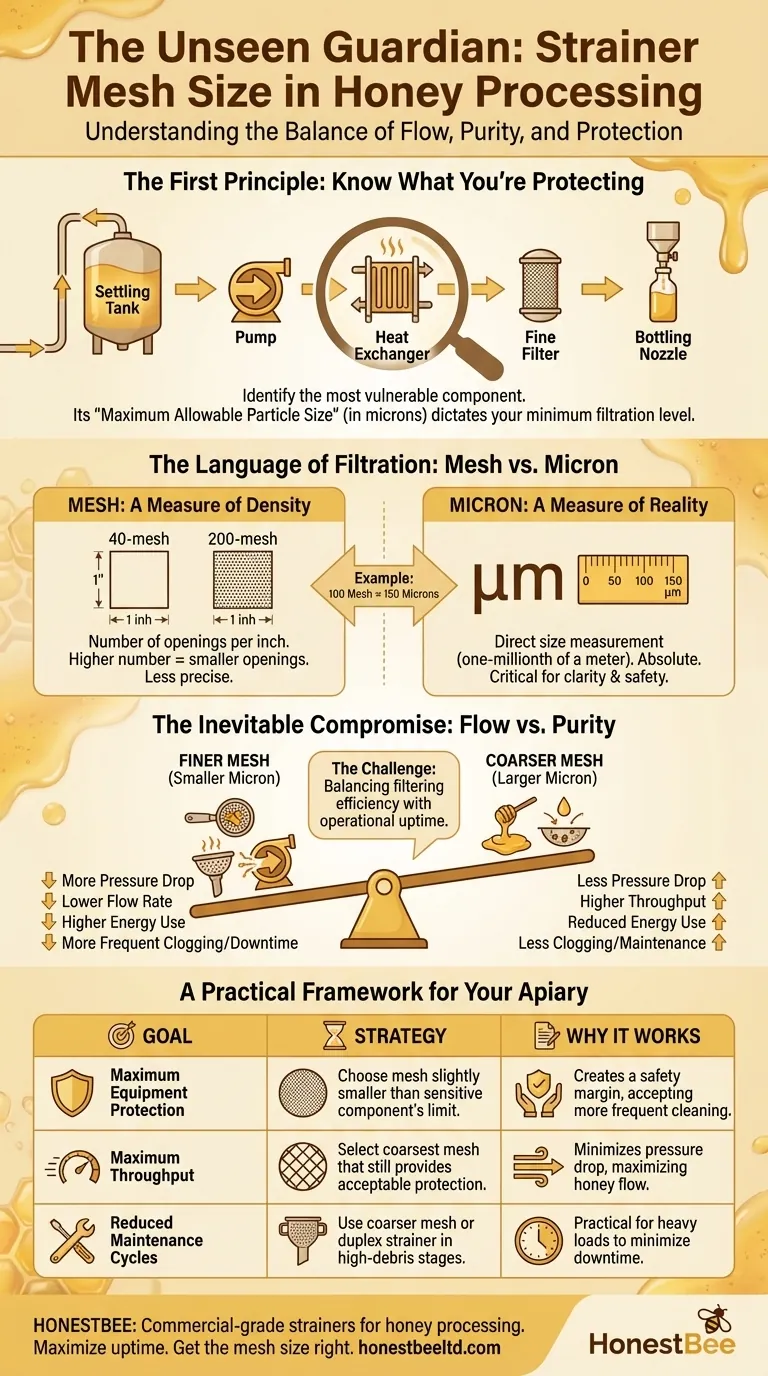

The First Principle: Know What You're Protecting

Before you choose a filter, you must know what it is guarding. The core function of a strainer is to protect the most sensitive piece of equipment downstream. Everything else is secondary.

In a commercial apiary's honey house, your processing line might include:

- Pumps: Essential for moving viscous honey from settling tanks to bottling lines.

- Heat Exchangers: Used to gently warm honey to improve flow, but their small channels are easily clogged.

- Fine Filters: Final stage filters that ensure clarity.

- Bottling Nozzles: Precision components that can jam, disrupting the entire packaging process.

Your task is to identify the most vulnerable of these. Check the manufacturer's technical specifications for a single number: the "Maximum Allowable Particle Size." This value, usually in microns, is your anchor. It dictates the absolute minimum level of filtration you require.

The Language of Filtration: Mesh vs. Micron

The terms are often confused, but the distinction is critical for making an engineering decision, not a guess.

Mesh: A Measure of Density

Mesh size is an old-world measurement. It simply refers to the number of openings in a one-inch line of a screen. A 40-mesh screen has 40 openings per inch; a 200-mesh screen has 200.

Higher mesh number = smaller openings. It’s simple, but not precise.

Micron: A Measure of Reality

A micron is a direct measurement of size (one-millionth of a meter). A filter with a 150-micron rating will stop particles that are 150 microns or larger. It is an absolute, unambiguous unit of measurement.

For honey processing, where clarity and equipment safety are paramount, thinking in microns is essential. For reference, a 100-mesh screen has openings of about 150 microns.

The Inevitable Compromise: Flow vs. Purity

Herein lies the psychological tension of system design. You can achieve near-perfect filtration, but it comes at a cost. Choosing a mesh size is always an exercise in balancing competing priorities.

The Physics of Pressure Drop

A finer mesh (higher number, smaller micron rating) creates more resistance. It has less open area for fluid to pass through. When you force a viscous liquid like honey through this restricted space, you create a significant pressure drop.

This can starve the intake of your pumps, reducing flow rates, increasing energy consumption, and putting mechanical strain on the entire system.

The Economics of Clogging

A finer mesh captures more debris. This is its job. But it also means it will clog faster.

Every time a strainer clogs, the line must be stopped, disassembled, cleaned, and reassembled. This isn't just a maintenance task; it's operational downtime. It’s lost throughput. It's labor cost. Choosing an unnecessarily fine mesh for a high-debris application (like first-pass filtering after extraction) is a recipe for constant interruption.

A Practical Framework for Your Apiary

Start with the micron rating of your most sensitive component. Then, temper that ideal with the reality of your operational goals.

| Primary Goal | Recommended Strategy | Why It Works |

|---|---|---|

| Maximum Equipment Protection | Choose a mesh with a micron rating slightly smaller than what your most sensitive component can tolerate. | Creates a safety margin, ensuring no damaging particles get through. You accept more frequent cleaning. |

| Maximum Throughput | Select the absolute coarsest mesh that still provides acceptable protection. | Minimizes pressure drop and clogging, keeping the honey flowing at the highest possible rate. |

| Reduced Maintenance Cycles | In high-debris stages, use a coarser mesh or a duplex strainer system that allows for cleaning on the fly. | A practical compromise for systems with heavy loads of wax and hive debris to minimize downtime. |

A strainer is more than just a screen; it's insurance for your entire operation. The right choice reflects a deep understanding of the trade-offs between perfect protection and practical performance.

At HONESTBEE, we supply commercial-grade strainers and beekeeping equipment built to withstand the unique demands of honey processing. Our wholesale focus ensures that apiaries and distributors get the durable, reliable hardware needed to protect vital machinery and maximize uptime. Getting the mesh size right is the first step to a smooth, efficient, and profitable operation. Contact Our Experts

Visual Guide

Related Products

- Conical Nylon Honey Strainer Filter Bag for Beekeeping and Honey Filtration

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- 10L Stainless Steel Electric Honey Press Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

Related Articles

- How Modern Bee Suits Combine Safety and Comfort Through Smart Design

- The Last Gate: Why a Simple Strainer Defines Honey Quality at Any Scale

- How Bee Jackets Outperform Full Suits in Hot Weather Without Sacrificing Protection

- The Strainer's Dilemma: How Simple Filtration Defines Your Honey's Identity

- How Beekeeping Suit Design Balances Protection, Comfort, and Durability