Honeybee combs are nature's precision engineering at its finest—a structural masterpiece that directly impacts colony health, honey yield, and brood viability. For commercial apiaries and distributors, optimizing comb management isn't just about aesthetics; it’s a science of leveraging hexagonal geometry, size variations, and spatial allocation to maximize operational efficiency.

The Engineering Marvel of Bee Comb

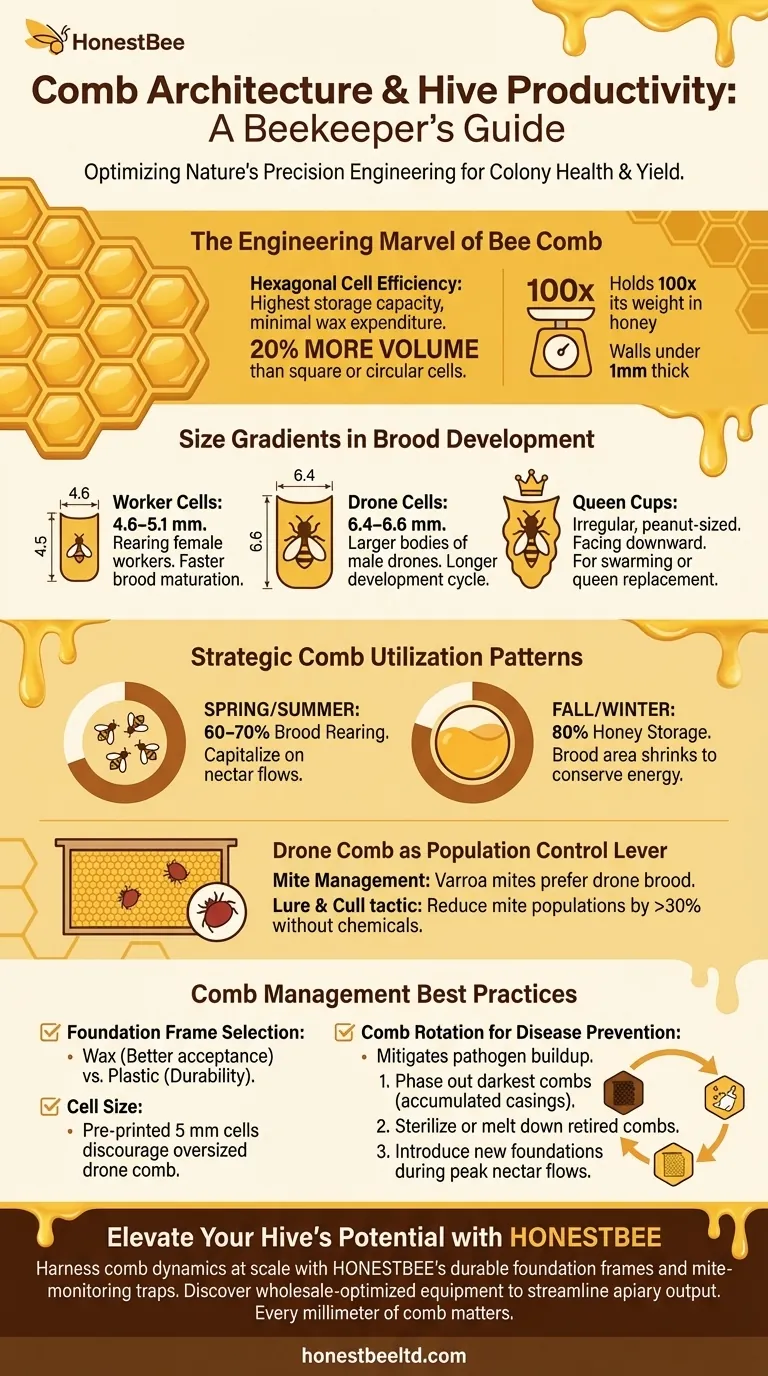

Hexagonal Cell Efficiency for Storage

Bees construct combs with hexagonal cells because this shape offers the highest storage capacity with minimal wax expenditure. Research shows hexagonal packing allows approximately 20% more volume than square or circular cells would, enabling efficient honey and pollen storage. The walls of these cells are just thick enough to support weight without collapsing—typically under a millimeter—yet can hold hundreds of times their weight in honey.

Size Gradients in Brood Development

Comb cells aren’t uniform; their diameters vary strategically:

- Worker cells: Measure between 4.6–5.1 mm, optimized for rearing female worker bees.

- Drone cells: Larger (6.4–6.6 mm) to accommodate male drones’ bulkier bodies.

- Queen cups: Irregular, peanut-sized cells facing downward, built only when the colony prepares to swarm or replace its queen.

These gradients aren’t arbitrary. Smaller worker cells accelerate brood maturation, while larger drone cells support the males’ longer development cycle.

Strategic Comb Utilization Patterns

Seasonal Comb Allocation Strategies

Colonies dynamically redistribute comb space based on seasonal needs:

- Spring/Summer: 60–70% of comb is allocated to brood rearing to capitalize on nectar flows.

- Fall/Winter: Hives shift toward 80% honey storage, with brood areas shrinking to conserve energy.

Top-bar hive studies reveal that bees left to self-organize (as in wild log hives) naturally balance these ratios—a principle commercial operations can emulate by monitoring comb occupancy monthly.

Drone Comb as Population Control Lever

Drone comb isn’t just for reproduction; it’s a tool for managing mite infestations. Varroa mites prefer drone brood due to their longer capped phase. By providing removable drone frames, beekeepers can:

- Lure mites away from worker brood.

- Cull infested drone cells before mites emerge.

This tactic can reduce mite populations by over 30% without chemical treatments.

Comb Management Best Practices

Foundation Frame Selection Criteria

When choosing foundation frames, prioritize:

- Wax vs. Plastic: Bees more readily accept pure beeswax foundations, but plastic offers durability for high-turnover apiaries.

- Cell Size: Pre-printed worker-sized cells (around 5 mm) discourage oversized drone comb in honey storage areas.

Comb Rotation for Disease Prevention

Rotating combs every 2–3 years mitigates pathogen buildup (e.g., American foulbrood spores). Key steps:

- Phase out darkest combs (accumulated pupal casings weaken wax).

- Sterilize or melt down retired combs.

- Introduce new foundations during peak nectar flows when bees rebuild fastest.

Elevate Your Hive’s Potential with HONESTBEE

For commercial beekeepers and distributors, comb architecture is the silent variable in hive productivity. HONESTBEE’s beekeeping supplies—from durable foundation frames to mite-monitoring drone traps—are designed to help you harness comb dynamics at scale. Discover how our wholesale-optimized equipment can streamline your apiary’s output—because every millimeter of comb matters.

Visual Guide

Related Products

- Heavy Duty Stainless Steel Honeycomb Cutter

- Hexagonal Bee Honeycomb Silicone Soap Mold by HONESTBEE

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Wooden Bee Brush with Double-Row Horsehair Bristles

- Plastic Handle Single Row Artificial Fiber Bee Brush

Related Articles

- How to Harvest Honeycombs Efficiently Without Compromising Quality or Bee Health

- The Benefits of Beekeeping for Your Vegetable Garden

- The Unseen Guardian: Strainer Mesh Size as a First Principle in Honey Processing

- Essential Beekeeping Equipment for Beginners: Functions, Selection, and Best Practices

- How to Perfect Honey Moisture Levels: A Beekeeper’s Guide to Refractometer Mastery