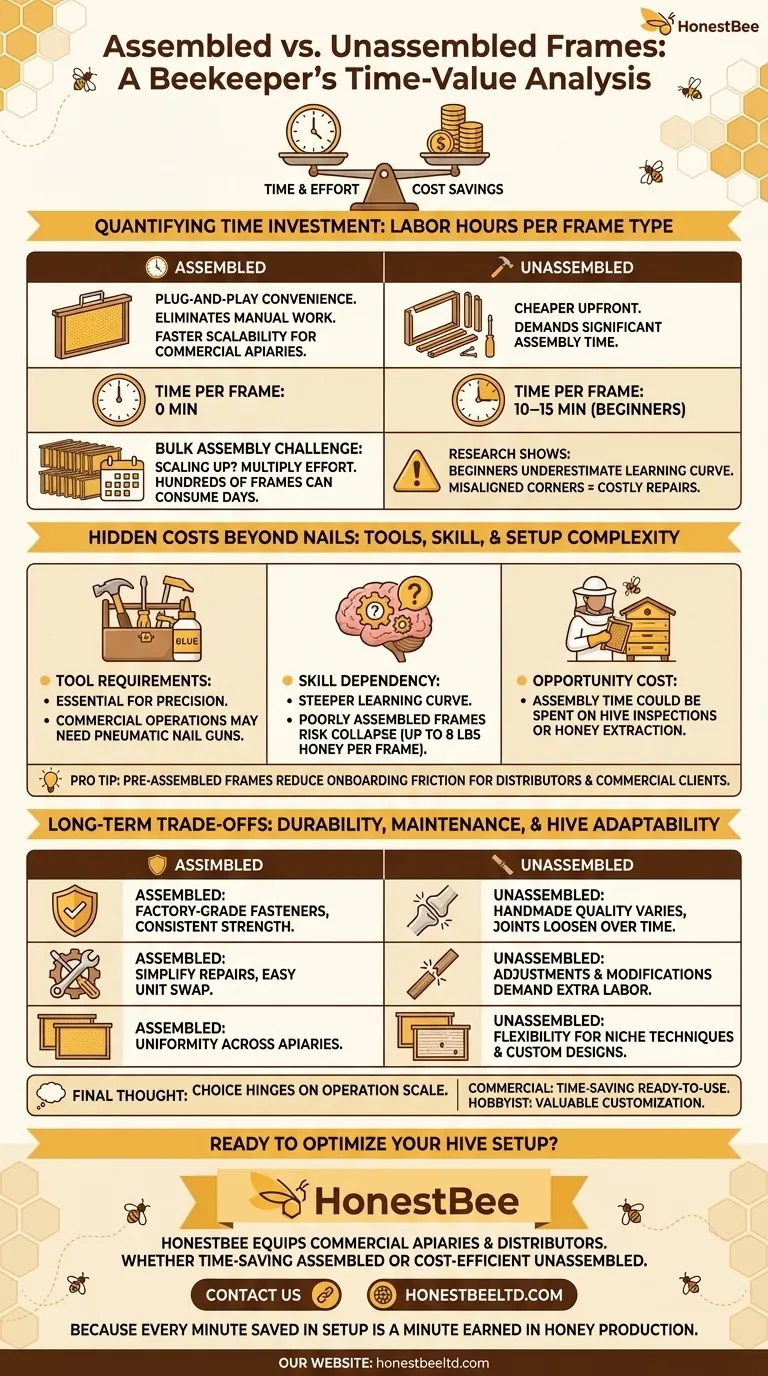

When building or expanding a beekeeping operation, every decision impacts productivity—especially frame selection. Should you invest in pre-assembled frames for immediate use, or does the cost savings of unassembled frames justify the extra labor? This guide breaks down the trade-offs between time, effort, cost, and functionality to help you optimize your hive setup.

Quantifying Time Investment: Labor Hours per Frame Type

Assembled frames offer plug-and-play convenience, eliminating hours of manual work. For commercial apiaries managing hundreds of hives, this time savings translates to faster scalability.

Unassembled frames, while cheaper upfront, demand significant assembly time:

- Per-frame labor: Constructing a single frame requires roughly 10–15 minutes for beginners, including measuring, nailing, and squaring corners.

- Bulk assembly challenges: Scaling up? Multiply this effort across hundreds of frames—a task that can consume days for large operations.

Key consideration: Research shows that beginners often underestimate the learning curve. Misaligned corners or weak joints can compromise frame durability, leading to costly repairs mid-season.

Hidden Costs Beyond Nails: Tools, Skill, and Setup Complexity

The true cost of unassembled frames extends beyond their price tag:

-

Tool requirements:

- A sturdy hammer, wood glue, and clamps are essential for precise assembly.

- Commercial operations may need pneumatic nail guns to streamline the process.

-

Skill dependency:

- Novice beekeepers face a steeper learning curve to achieve professional-grade results.

- Poorly assembled frames risk collapsing under the weight of honey (up to 8 lbs per frame), jeopardizing hive health.

-

Opportunity cost:

- Time spent assembling frames could be allocated to hive inspections or honey extraction—tasks that directly impact yield.

Pro tip: For distributors supplying equipment to commercial clients, pre-assembled frames reduce onboarding friction, letting beekeepers focus on production.

Long-Term Trade-offs: Durability, Maintenance, and Hive Adaptability

Durability:

- Factory-assembled frames often use industrial-grade fasteners, ensuring consistent strength.

- Handmade frames may vary in quality, requiring frequent replacements if joints loosen over time.

Maintenance:

- Pre-assembled frames simplify repairs; beekeepers can swap units without disassembly.

- Custom-built frames allow for modifications (e.g., deeper grooves for foundationless beekeeping), but adjustments demand additional labor.

Adaptability:

- Need to standardize equipment across apiaries? Assembled frames guarantee uniformity.

- Prefer experimenting with frame designs? Unassembled kits offer flexibility for niche techniques.

Final thought: The choice hinges on your operation’s scale and priorities. Time-strapped commercial beekeepers benefit from ready-to-use frames, while hobbyists might value the customization of DIY kits.

Ready to Optimize Your Hive Setup?

HONESTBEE equips commercial apiaries and distributors with high-performance beekeeping supplies—whether you prioritize time-saving assembled frames or cost-efficient unassembled kits. Contact us to discuss bulk solutions tailored to your productivity goals.

Because every minute saved in setup is a minute earned in honey production.

Visual Guide

Related Products

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Assembled Wooden Bee Frames with Plastic Foundation for Durability and Convenience by HONESTBEE

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

- Heavy-Duty Stainless Steel Clip-On Frame Perch

Related Articles

- Bee Space: The Architectural Principle Governing a Honeybee Society

- How Honey Frames Naturally Manage Queen Bees Without Compromising Colony Health

- How to Optimize Frame Count in 10-Frame Hives for Maximum Honey and Healthy Bees

- How Frame and Comb Selection Transforms Hive Health and Honey Production

- Are Your Beekeeping Frames Holding You Back? Unpacking the Hidden Trade-offs in Hive Management