The Lingering Question After the Press: What Do I Do With All This Wax?

After a long day of honey extraction, you're left with shiny buckets of liquid gold. But then there's the other pile: the compressed wax cakes from your honey press. If you're like many commercial beekeepers, you might view these wax remnants as an unavoidable byproduct, perhaps even a nuisance, wondering if you're truly getting the most out of your harvest. Is it just "spent comb," or is there more to it?

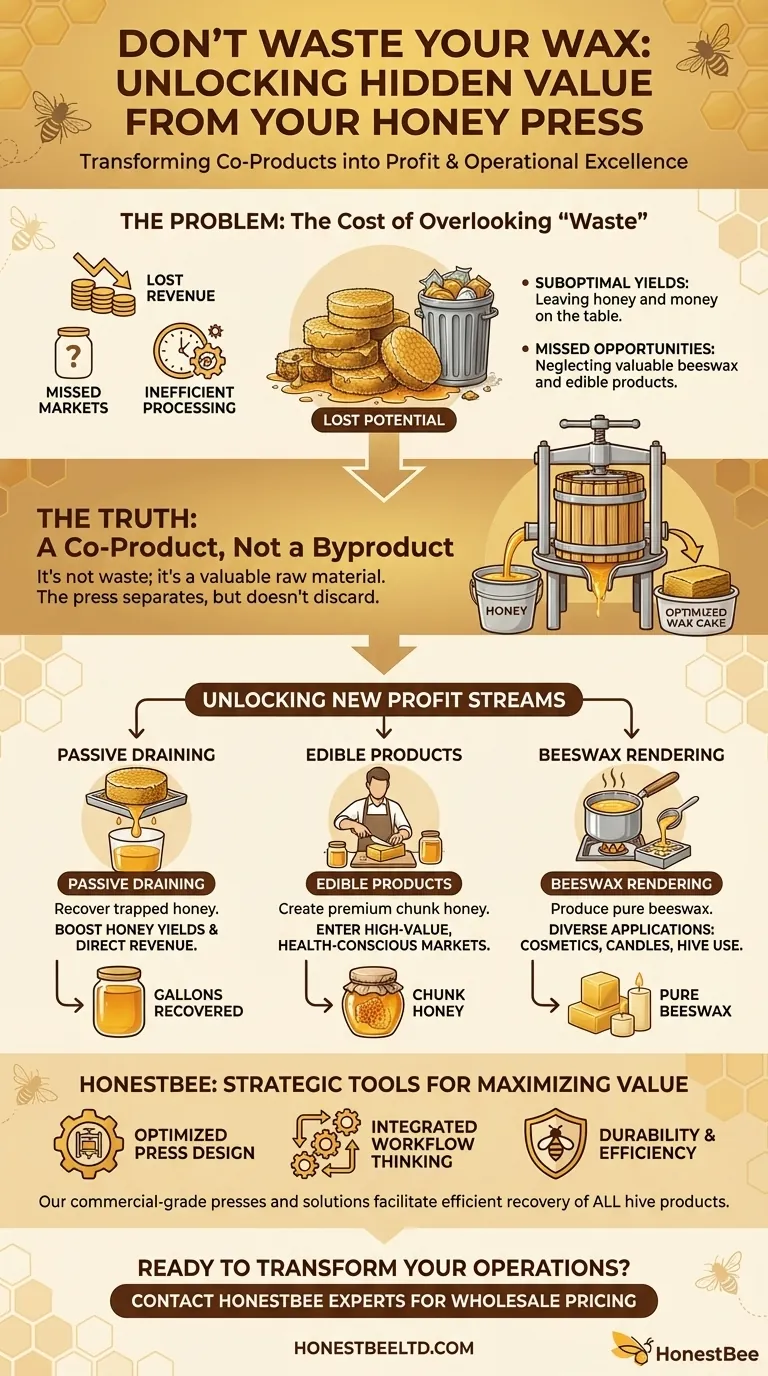

The Cost of Overlooking "Waste": Lost Revenue and Inefficient Operations

This question isn't just about tidiness; it's about the bottom line. For many commercial apiaries and beekeeping equipment distributors, a common frustration is the perceived "waste" left behind after the honey press has done its job. This leads to:

- Suboptimal Yields: Leaving significant honey trapped in the wax means leaving money on the table. Every drop counts when you're operating at scale.

- Missed Market Opportunities: Discarding or neglecting wax means losing out on valuable beeswax or premium edible products.

- Inefficient Processing: If you're not systematically handling this co-product, you're adding unnecessary steps or costs to your operation, impacting overall productivity and profitability.

- Environmental Concerns: In an industry increasingly focused on sustainability, discarding valuable resources can be seen as wasteful, impacting your brand reputation.

Many try to "solve" this by simply throwing the wax away, or perhaps attempting a rudimentary, messy melting process for the wax. These stop-gap measures fail because they don't address the fundamental nature of what's left in the press.

The Truth About Pressed Wax: A Co-Product, Not a Byproduct

The core principle often missed is this: a honey press efficiently separates honey from wax, but it doesn't discard the wax. Instead, it consolidates it into a manageable form that is inherently valuable. What remains in the press is not waste; it’s a wax cake—a dense, compacted disc or block of beeswax still rich with residual honey.

Why Your Current Methods Fall Short

- "Just throw it out": This is the most costly "solution," ignoring significant potential revenue from both honey and wax.

- "Melt it all down immediately": Attempting to melt the honey-saturated wax without proper pre-treatment is inefficient and often results in a sticky, impure mess, wasting energy and time. The issue is the high honey content still trapped within the wax's intricate structure, which needs to be addressed before true "pure" beeswax can be rendered. Your press, while powerful, doesn't evaporate the honey; it just squeezes out the free-flowing liquid.

Understanding this distinction is crucial. The wax cake is a raw material with multiple destinies, each offering distinct commercial value. Its potential is dictated by a few key trade-offs: the desire for maximum honey yield, the creation of an edible product, or the harvesting of pure beeswax.

Beyond Extraction: Strategic Tools for Maximizing Wax Value

To truly solve the "what to do with the wax" dilemma, you need more than just a press. You need a strategic approach that acknowledges the wax cake as a valuable co-product. This requires tools and methods designed to efficiently recover residual honey, prepare edible products, or purify beeswax.

At HONESTBEE, we understand that the quality of your primary extraction equipment significantly impacts the subsequent handling of your wax. Our commercial-grade honey presses are designed not only for efficient honey separation but also to produce a consistent, manageable wax cake that sets the stage for maximum resource recovery.

How Our Solutions Empower Your Operations:

- Optimized Press Design: Our presses create a dense wax cake, ideal for further processing, whether you're passively draining for more honey or preparing for rendering.

- Integrated Workflow Thinking: We don't just sell presses; we offer solutions that fit into your larger operational workflow, helping you conceptualize the entire extraction and co-product recovery process. This means your "waste" product becomes an input for a new revenue stream.

- Durability and Efficiency: HONESTBEE equipment is built to handle the rigorous demands of commercial apiaries, ensuring that your initial investment in a honey press facilitates long-term, efficient recovery of all your valuable hive products, not just the honey.

Unlocking New Profit Streams and Operational Excellence

Imagine a world where your honey extraction "waste" is a consistent source of new revenue. By adopting a comprehensive approach to managing pressed wax, guided by quality equipment and strategic insight, you can:

- Boost Honey Yields Significantly: Through passive draining, you can recover gallons of honey that would otherwise be discarded, directly increasing your primary product revenue.

- Enter Premium Edible Markets: Transform a portion of your wax into sought-after "chunk honey" – a high-value, natural product that appeals to health-conscious consumers.

- Generate Pure Beeswax for Diverse Applications: Produce clean, rendered beeswax, opening doors to new markets in cosmetics, candles, and other artisan products, or simply reusing it for your own hive management.

- Enhance Sustainability and Brand Image: Demonstrate a commitment to zero-waste practices, appealing to a growing consumer base that values environmentally responsible businesses.

With the right equipment and a clear strategy, the pressed wax from your honey press ceases to be a problem and becomes a pathway to new possibilities and increased profitability for your commercial apiary.

Ready to transform your "waste" into valuable assets and optimize your beekeeping operations? HONESTBEE supplies durable, commercial-grade beekeeping supplies and equipment. Let us help you choose the right equipment and strategy to maximize every aspect of your honey harvest. Contact our experts today to discuss your unique projects or issues and unlock wholesale pricing: Contact Our Experts

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

Related Articles

- Beyond Brute Force: Why Your Honey Press Is Costing You Quality and Yield

- Beyond the Extractor: How Honey Presses Turn Waste into Profit for Commercial Apiaries

- Is Your Honey Press Underperforming? The Overlooked Secret to Maximizing Your Yield

- How to Optimize Centrifugal Honey Extraction for Different Hive Types

- The Beekeeper's Dilemma: The Brutal, Beautiful Logic of the Honey Press