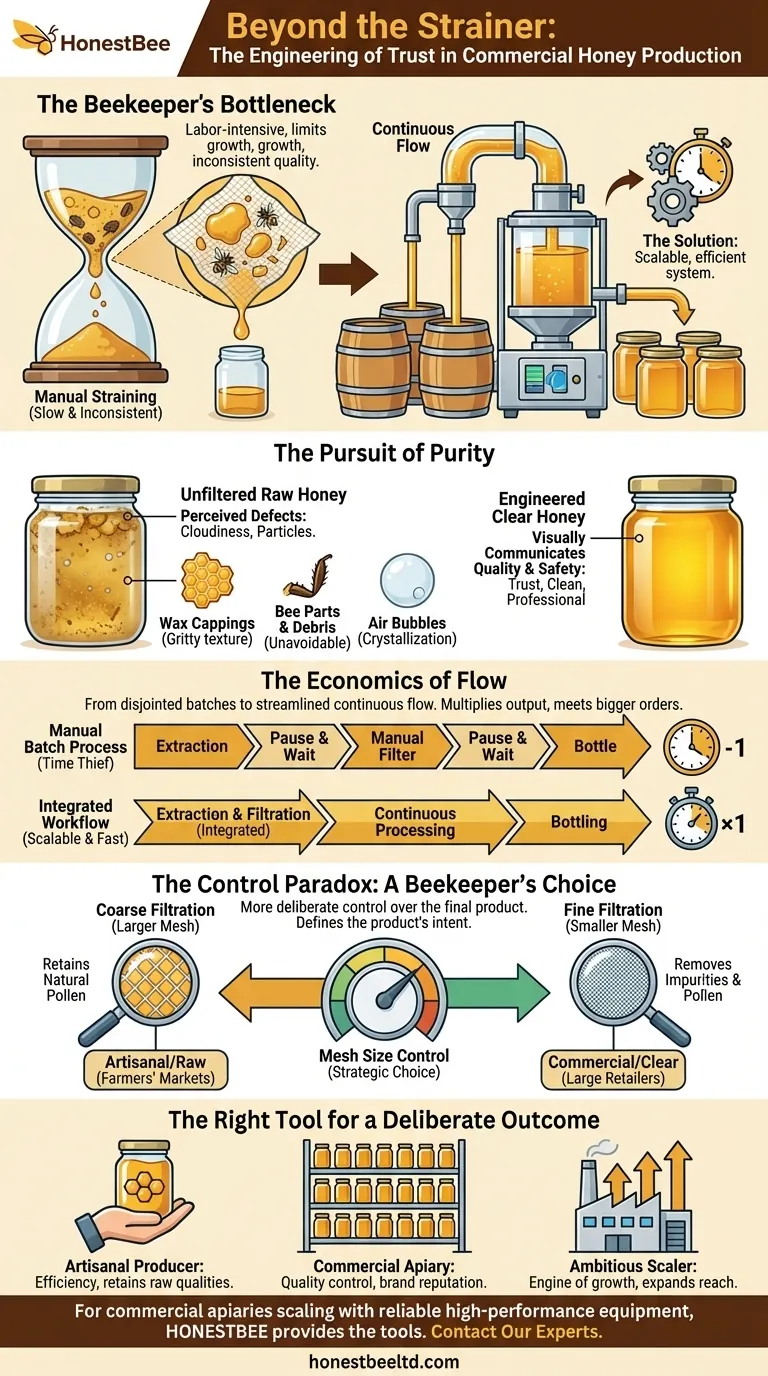

The Beekeeper's Bottleneck

Imagine a commercial apiary after a successful harvest. Drums of raw honey, rich with the scent of nectar, await processing. But between this raw bounty and a market-ready product lies a formidable obstacle: the slow, sticky, and laborious process of manual straining.

For generations, beekeepers have used cheesecloth and mesh screens. It’s an artisanal method that works for a few hives, but at a commercial scale, it becomes a bottleneck. It’s inconsistent, physically demanding, and fundamentally limits the operation's potential. This isn't just a process problem; it's a growth problem. The real challenge is moving from a craft to a scalable system without losing the essence of the product.

The Pursuit of Purity

The modern consumer has a deeply ingrained psychological model for honey: it should be pure, golden, and brilliantly clear. Cloudiness or suspended particles, even if they are natural elements like pollen or wax, can be perceived as defects.

This isn't about deception; it's about trust. A crystal-clear product visually communicates quality and safety. It’s an unspoken promise that the product is clean and professionally handled.

Engineering Consistency

A honey filtering machine is designed to deliver on that promise with engineering precision. It systematically removes impurities that are a natural byproduct of extraction:

- Wax Cappings: Tiny fragments that can cloud the honey and lead to a gritty texture.

- Bee Parts & Debris: Unavoidable elements from the hive that must be removed.

- Air Bubbles: Introduced during extraction, these are eliminated to improve clarity and prevent premature crystallization.

By removing these variables, the machine produces honey with a consistent texture, a longer shelf life, and the visual appeal required to compete on a commercial shelf. It transforms a product of nature into an asset of commerce.

The Economics of Flow

Time is the most valuable, non-renewable resource in any business. Manual filtering is a thief of time. It’s a batch process that forces the entire operation to pause and wait.

A honey filtering machine fundamentally changes the workflow from a series of disjointed batches into a continuous, streamlined flow. Many systems integrate extraction and filtration, turning two separate, time-consuming tasks into a single, efficient operation.

This isn’t just about saving a few hours. It’s about multiplying output. It enables an apiary to process larger volumes faster, meet bigger orders, and scale its operations without a proportional increase in manual labor. This is how a successful local beekeeping business becomes a regional supplier.

The Control Paradox: A Beekeeper's Choice

Introducing a machine into a natural process creates a fascinating paradox. While it seems like automation removes control, a filtering machine actually gives the beekeeper more deliberate control over the final product than ever before.

The key lies in the filter's mesh size. This isn't an on/off switch; it's a dial.

The Pollen Question

One of the most significant debates in the honey world is about pollen. Some consumers seek it for its perceived health benefits, while others demand the absolute clarity that comes from its removal.

A filtering machine resolves this debate by turning it into a strategic choice.

- Coarse Filtration (Larger Mesh): Removes large debris like wax while intentionally leaving most of the natural pollen. This is perfect for producing "raw" or artisanal honey for farmers' markets or health-conscious consumers.

- Fine Filtration (Smaller Mesh): Removes nearly all suspended particles, including pollen, to create the exceptionally clear honey demanded by large retailers and food service industries.

The machine empowers the beekeeper to define their product, not just clean it.

The Right Tool for a Deliberate Outcome

The decision to integrate a honey filtering machine is a decision about intent. What kind of business do you want to run?

- For the Artisanal Producer: The machine is a tool for efficiency, removing the drudgery of straining so you can focus on other aspects of your craft, all while retaining the raw qualities your customers love.

- For the Commercial Apiary: It's an essential investment in quality control and brand reputation, ensuring every jar meets the high standards of the mass market.

- For the Ambitious Scaler: It's the engine of growth, unlocking the processing capacity needed to expand your reach and profitability.

Ultimately, this technology offers precision, transforming a variable harvest into a consistent, high-value product line. It’s about honoring the work of the bees by ensuring the final product reflects the highest standard of quality and care.

For commercial apiaries and distributors committed to scaling their operations with reliable, high-performance equipment, HONESTBEE provides the tools necessary to achieve that standard. Contact Our Experts

Visual Guide

Related Products

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Professional Honey Filter with Tripod Support Stand

- Professional Stainless Steel Honey Filter with Support Handle

- Two-Stage Plastic Honey Filter for Buckets

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

Related Articles

- The Beekeeper's Dilemma: The Brutal, Beautiful Logic of the Honey Press

- Optimizing Honey Filtration: How Mesh Sizes Shape Quality and Market Appeal

- How Honey Bottle Designs Combine Convenience, Safety, and Sustainability

- From Hive to Jar: The Elegant Engineering of a Simple Honey Strainer

- How to Accurately Test Honey Readiness: Science-Backed Methods for Beekeepers