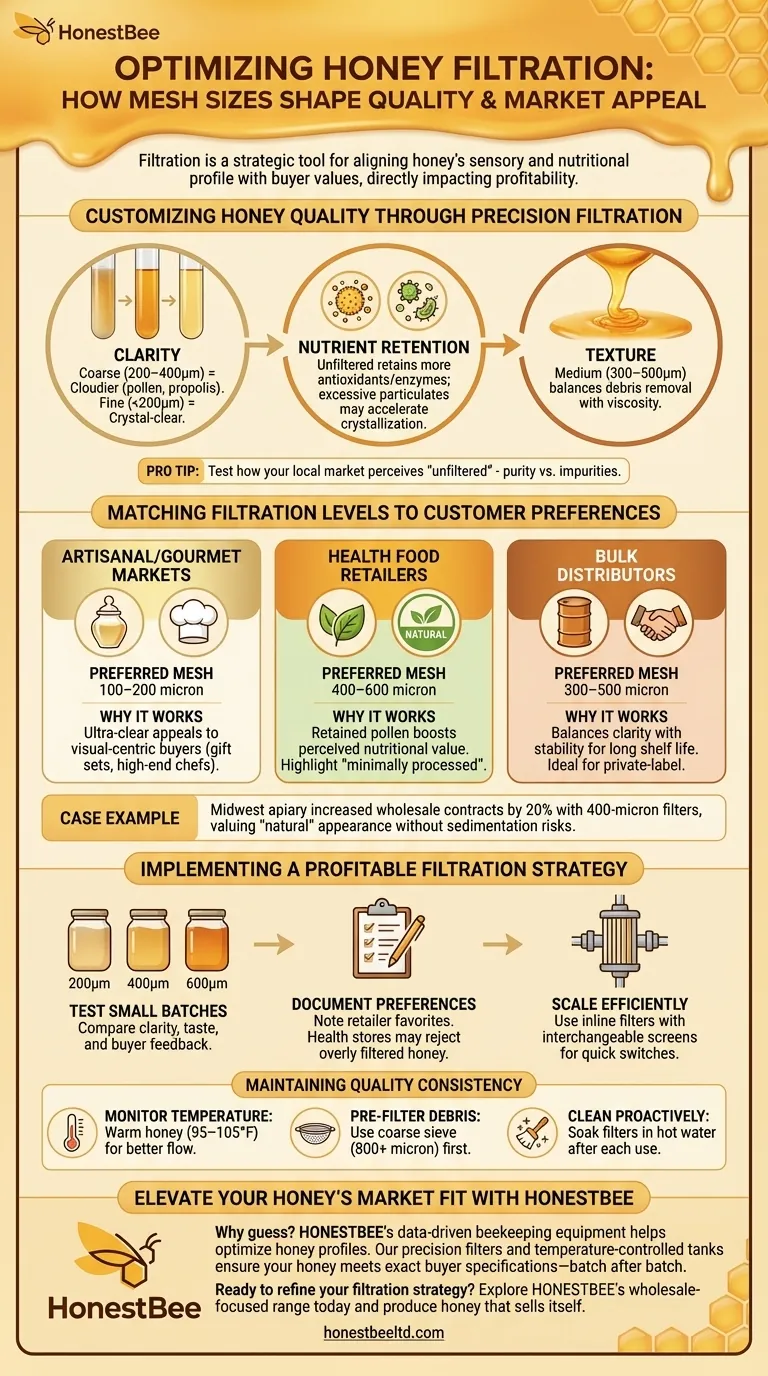

For beekeepers, filtration isn’t just about clarity—it’s a strategic tool to align honey’s sensory and nutritional profile with what buyers value most. Whether supplying artisanal markets or bulk distributors, selecting the right filter mesh size directly impacts profitability. Here’s how to tailor your approach.

Customizing Honey Quality Through Precision Filtration

How Filter Mesh Size Impacts Honey Characteristics

Honey filtration balances three key factors:

- Clarity: Coarse filters (e.g., 200–400 micron) retain pollen and propolis, creating a cloudier product favored by health-conscious consumers. Fine filters (under 200 micron) yield crystal-clear honey preferred for gourmet retail.

- Nutrient Retention: Studies suggest unfiltered honey retains higher levels of antioxidants and enzymes, but excessive particulates can accelerate crystallization.

- Texture: Medium filtration (300–500 micron) strikes a balance, removing debris while preserving viscosity for easy pouring.

Pro Tip: Have you tested how your local market perceives "unfiltered" labels? Some buyers equate minimal processing with purity, while others associate it with impurities.

Matching Filtration Levels to Customer Preferences

Segment your strategy based on buyer priorities:

1. Artisanal/Gourmet Markets

- Preferred Mesh: 100–200 micron

- Why It Works: Ultra-clear honey appeals to visual-centric buyers (e.g., gift sets, high-end chefs). Pair with glass jars to emphasize transparency.

2. Health Food Retailers

- Preferred Mesh: 400–600 micron

- Why It Works: Retained pollen boosts perceived nutritional value. Highlight "minimally processed" on labels.

3. Bulk Distributors

- Preferred Mesh: 300–500 micron

- Why It Works: Balounces clarity with stability for long shelf life. Ideal for private-label brands.

Case Example: A Midwest apiary increased wholesale contracts by 20% after switching to 400-micron filters, as buyers valued the honey’s "natural" appearance without sedimentation risks.

Implementing a Profitable Filtration Strategy

Step-by-Step Guide to Adjusting Filter Settings

- Test Small Batches: Process identical honey with 200, 400, and 600-micron filters. Compare clarity, taste, and buyer feedback.

- Document Preferences: Note which retailers or distributors favor each type. Health stores may reject overly filtered honey.

- Scale Efficiently: Use inline filters with interchangeable screens (e.g., stainless steel mesh) to switch between profiles without downtime.

Maintaining Quality Consistency Across Batches

- Monitor Temperature: Warm honey (95–105°F) flows better through fine filters without clogging.

- Pre-Filter Debris: A coarse sieve (800+ micron) removes wax chunks before final filtration, extending mesh lifespan.

- Clean Proactively: Residual sugars breed bacteria. Soak filters in hot water after each use.

Elevate Your Honey’s Market Fit with HONESTBEE

Why guess filtration needs when data-driven tools exist? HONESTBEE’s beekeeping equipment helps commercial apiaries and distributors optimize honey profiles with precision filters designed for high-volume processing. From adjustable mesh screens to temperature-controlled tanks, our solutions ensure your honey meets exact buyer specifications—batch after batch.

Ready to refine your filtration strategy? Explore HONESTBEE’s wholesale-focused range today and produce honey that sells itself.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Stainless Steel Honey Filter with Support Handle

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Two-Stage Plastic Honey Filter for Buckets

Related Articles

- The Silent Collapse: Why Strong Beehives Die Over Winter

- The Precision Imperative: Why a 30-Second Calibration Prevents a Costly Harvest Failure

- Beyond the Solid Floor: A Systems Approach to Hive Ventilation and Pest Control

- Is Your Honey Tank Holding Your Business Hostage? How to Choose a Size That Fuels Growth, Not Frustration

- The Hidden Threat After Harvest: Why a Simple Lid Prevents Apiary Disaster