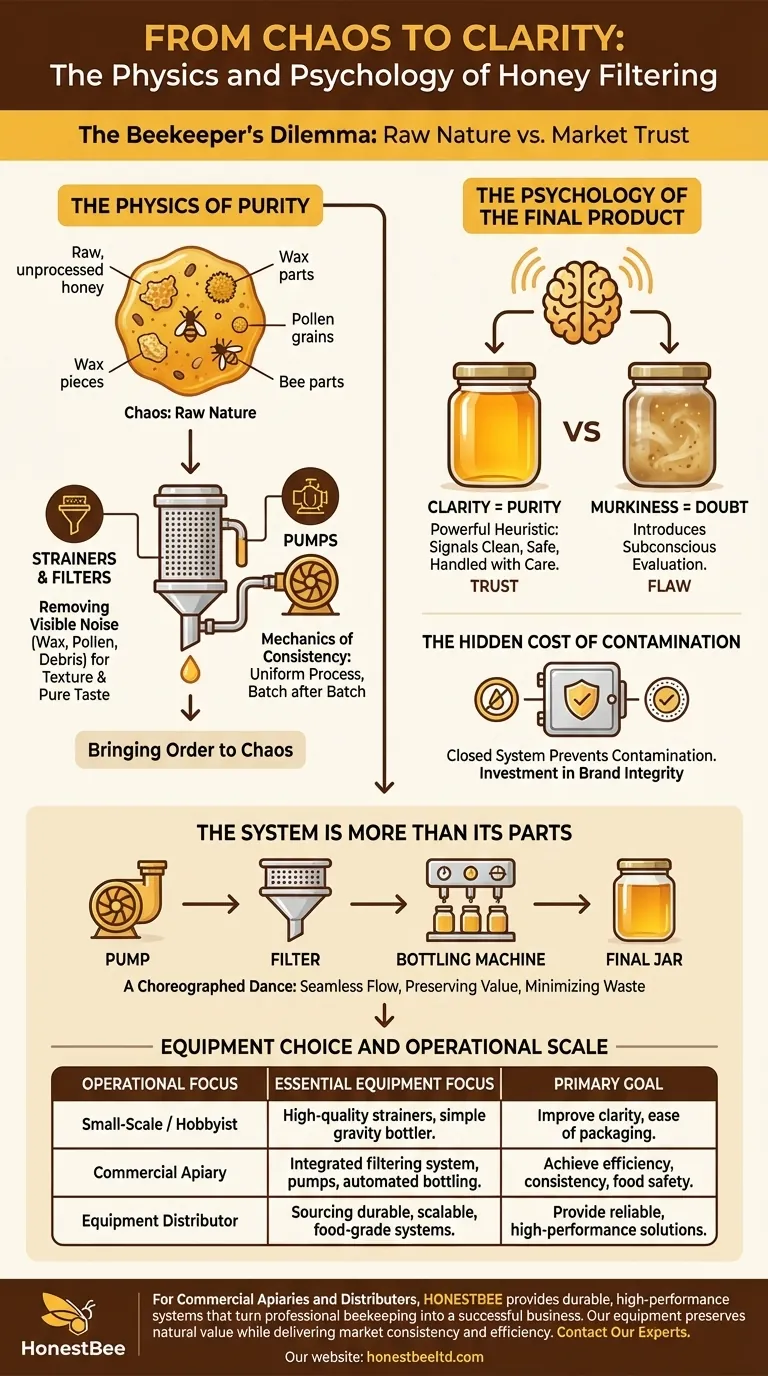

The Beekeeper's Dilemma: Raw Nature vs. Market Trust

Raw honey, freshly extracted from the comb, is a chaotic marvel. It's a thick, fragrant slurry of pure nectar, but also wax cappings, stray pollen grains, and even microscopic bee parts.

In its raw state, it represents untamed nature. But for the consumer, this chaos can be perceived as a flaw. The journey from the hive to the jar is therefore a process of bringing order to this chaos, and the tools used for this transformation are not mere conveniences—they are the arbiters of quality and trust.

The Physics of Purity

At its core, honey processing is an exercise in applied physics. It's about separating elements to preserve the most valuable ones.

Removing the Visible Noise

The first and most obvious task is removing physical impurities. Strainers and filters act as gatekeepers, systematically blocking debris.

This isn't just about aesthetics. Removing wax particles improves texture. Eliminating foreign matter ensures a pure taste. This physical separation is the first step in honoring the honey's intrinsic quality.

The Mechanics of Consistency

Consumers don't buy a single jar of honey; they often buy into a brand. They expect the honey they purchase in December to have the same clarity and texture as the one they bought in June.

This is where equipment like pumps and integrated filtering systems becomes critical. They ensure a uniform process, creating a consistent product batch after batch. Consistency isn't boring; it’s a promise to the customer, fulfilled by mechanical precision.

The Psychology of the Final Product

What a consumer sees on the shelf is not just honey; it's a collection of signals that inform their decision to buy. The right equipment helps control these signals.

Clarity as a Signal for Purity

Why do we associate clarity with quality? Psychologically, clear honey signals a clean, safe, and carefully handled product. It's a powerful heuristic—a mental shortcut our brains use to assess purity without having to taste it first.

Murkiness, on the other hand, introduces doubt. By ensuring brilliant clarity, proper filtering equipment directly addresses this subconscious evaluation, making the product more appealing and trustworthy on a crowded shelf.

The Hidden Cost of Contamination

A well-designed filtering system, built with food-grade materials, does more than just strain honey. It creates a closed, sanitary environment that prevents contamination.

The risk of neglect here isn't just a compromised batch. It's the erosion of a hard-won reputation. Maintaining your equipment—regular cleaning, checking for wear, and ensuring seals are tight—is a direct investment in brand integrity.

The System Is More Than Its Parts

A successful commercial operation relies on an integrated system where each component works in concert.

From Pump to Bottle: A Journey of Preservation

Think of the process as a carefully choreographed dance. A pump moves the honey at a precise rate, avoiding agitation that could damage its delicate compounds. The honey flows through filters that purify it, then moves to a bottling machine that provides accurate, clean fills.

This seamless flow is the hallmark of a professional operation. It minimizes waste, saves labor, and, most importantly, protects the honey's value at every stage.

Equipment Choice and Operational Scale

The "right" equipment is relative to your ambition. Your choice reflects a commitment to quality, tailored to the scale of your operation.

| Operational Focus | Essential Equipment Focus | Primary Goal |

|---|---|---|

| Small-Scale / Hobbyist | High-quality strainers, simple gravity bottler. | Improve clarity and ease of packaging. |

| Commercial Apiary | Integrated filtering system with pumps, strainers, and automated bottling machines. | Achieve efficiency, consistency, and food safety. |

| Equipment Distributor | Sourcing a range of durable, scalable, and food-grade systems for diverse customer needs. | Provide reliable, high-performance solutions. |

For commercial apiaries and distributors, the stakes are higher. You aren't just producing honey; you are managing a supply chain where quality and efficiency are paramount. This requires robust, reliable, and scalable equipment designed for high-volume work. As a wholesale-focused supplier, HONESTBEE provides the durable, high-performance systems that turn professional beekeeping into a successful business.

Our equipment is designed to preserve the natural value of your honey while delivering the consistency and efficiency your market demands. To build an operation founded on quality and trust, you need a partner who understands the physics and psychology of a perfect product.

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

Related Articles

- How to Heat Honey Without Destroying Its Nutrients: Science-Backed Methods

- How Bee Jackets Outperform Full Suits in Hot Weather Without Sacrificing Protection

- How Flow Frames Revolutionize Beekeeping with Bee-Friendly Honey Harvesting

- Beyond the Scrape: The Silent Killer in Your Beehives and How to Stop It

- How Thoughtful Pocket Design Transforms Hive Inspections for Beekeepers