Harvesting honey at the right moment is both an art and a science. While experienced beekeepers often rely on visual cues like capping completeness, modern apiculture demands more precise verification to prevent spoilage and maximize yield. This guide reveals advanced, actionable techniques to validate honey readiness—from biological indicators to instrument-assisted testing—helping you make informed harvest decisions.

The Biology of Honey Readiness

How Bees Signal Harvest Preparedness

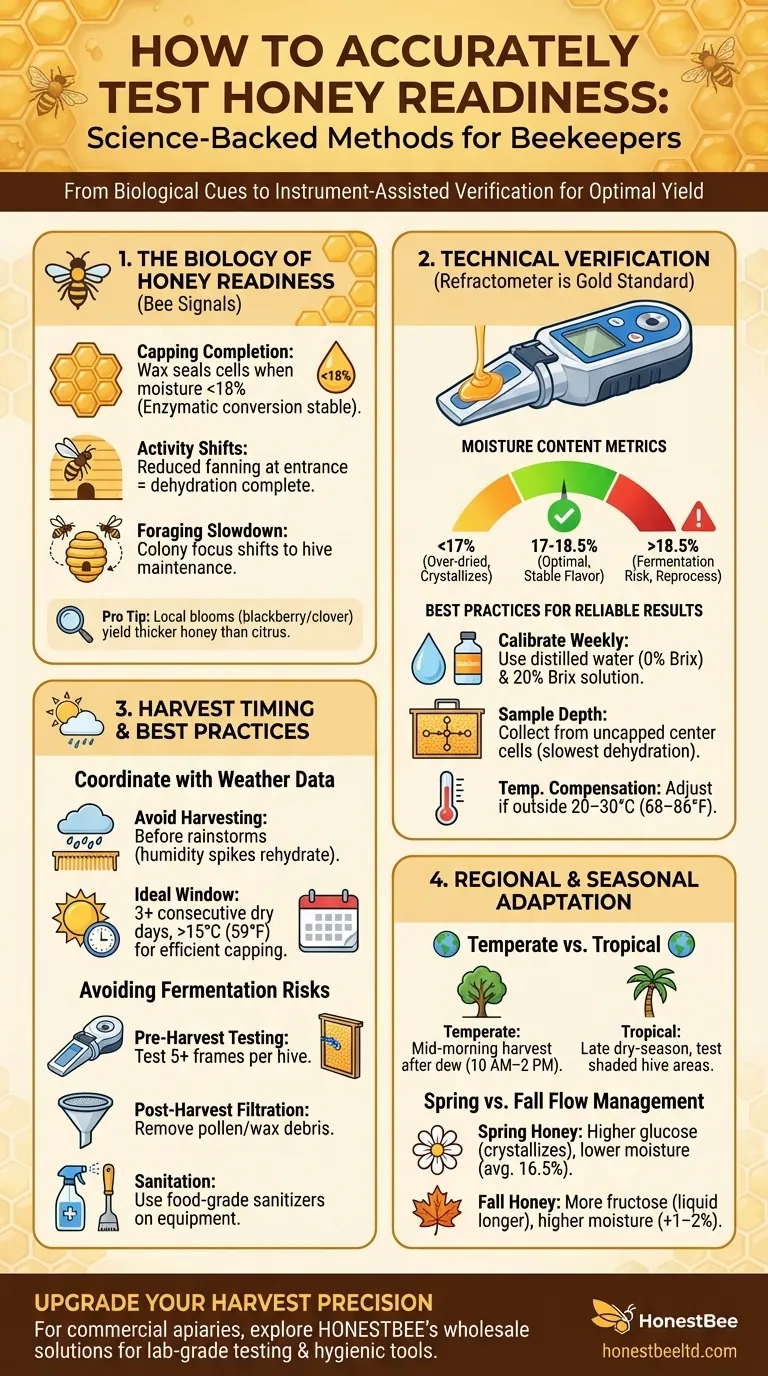

Honeybees instinctively know when their product is ready for harvest. They communicate this through three observable behaviors:

- Capping Completion: Workers seal cells with wax when moisture content drops below roughly 18%, indicating enzymatic conversion of nectar into stable honey.

- Activity Shifts: Reduced fanning at the hive entrance suggests dehydration is complete.

- Foraging Slowdown: Fewer bees returning with nectar implies the colony has shifted focus to hive maintenance.

Research shows colonies in temperate regions cap honey faster during dry, warm spells, while tropical bees may delay capping due to higher ambient humidity.

Nectar Flow Patterns Across Climates

- Temperate Zones: Spring flows (April–June) often produce honey with lower moisture (15–17%) due to steady evaporation conditions.

- Tropical Regions: Consistent humidity requires longer ripening periods; unripe honey here averages 19–22% moisture pre-capping.

Pro Tip: Monitor local bloom cycles—blackberry or clover flows typically yield thicker honey than citrus or eucalyptus blooms.

Technical Verification Methods

Refractometer Calibration Protocols

A refractometer is the gold standard for testing honey moisture. For reliable results:

- Calibrate Weekly using distilled water (0% Brix) and a 20% Brix solution.

- Sample Depth Matters: Collect honey from uncapped cells near the hive center, where dehydration is slowest.

- Temperature Compensation: Adjust readings if honey is outside 20–30°C (68–86°F); warmer samples read artificially high.

Key Metric: Honey below 18.6% moisture resists fermentation; 17–18% is ideal for long-term storage.

Interpreting Moisture Content Metrics

- <17%: Over-dried; may crystallize prematurely.

- 17–18.5%: Optimal for flavor stability.

- >18.5%: Risk of fermentation; requires reprocessing or immediate refrigeration.

Harvest Timing Best Practices

Coordinating Capping Observations with Weather Data

Pair bee behavior with hyperlocal forecasts:

- Avoid Harvesting before rainstorms; humidity spikes can rehydrate uncapped honey.

- Ideal Window: 3+ consecutive dry days with temperatures above 15°C (59°F) to ensure bees can cap efficiently.

Avoiding Fermentation Risks Through Testing

Fermentation occurs when wild yeasts metabolize sugars in high-moisture honey. Prevent it by:

- Pre-Harvest Testing: Use a refractometer on 5+ frames per hive.

- Post-Harvest Filtration: Remove pollen and wax debris that can harbor moisture.

- Sanitation: As referenced in apiculture studies, wiping equipment interiors with food-grade sanitizers reduces microbial contamination risks.

Regional Adaptation Strategies

Temperate vs. Tropical Harvest Windows

- Temperate Climates: Harvest mid-morning after dew evaporates (10 AM–2 PM).

- Tropical Areas: Prioritize late dry-season harvests; test honey from shaded hive areas first.

Case Study: Spring vs. Fall Flow Management

A 3-year apiary trial showed:

- Spring Honey: Higher glucose content (prone to crystallization) but lower moisture (avg. 16.5%).

- Fall Honey: More fructose (stays liquid longer) but averages 1–2% higher moisture; requires closer monitoring.

Upgrade Your Harvest Precision

For commercial apiaries and distributors, HONESTBEE’s refractometers and hygienic extraction tools help standardize honey quality at scale. Explore our wholesale solutions to equip your operation with lab-grade testing in the field.

Final Thought: Beyond instruments, trust your bees—they’ve perfected this process for millennia. Your role is to interpret their cues with informed precision.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

Related Articles

- How Honey Refractometers Protect Profits: A Science-Backed Guide to Harvest Timing and Quality Control

- The Professional’s Guide to Honey Refractometer Calibration: Ensuring Quality, Protecting Profit

- The Second Half of the Measurement: Protecting the Integrity of Your Honey Refractometer

- From Profit to Spoilage: The One Number Every Commercial Beekeeper Must Know

- Mastering Honey Refractometer Basics: A Guide to Precision and Profitability