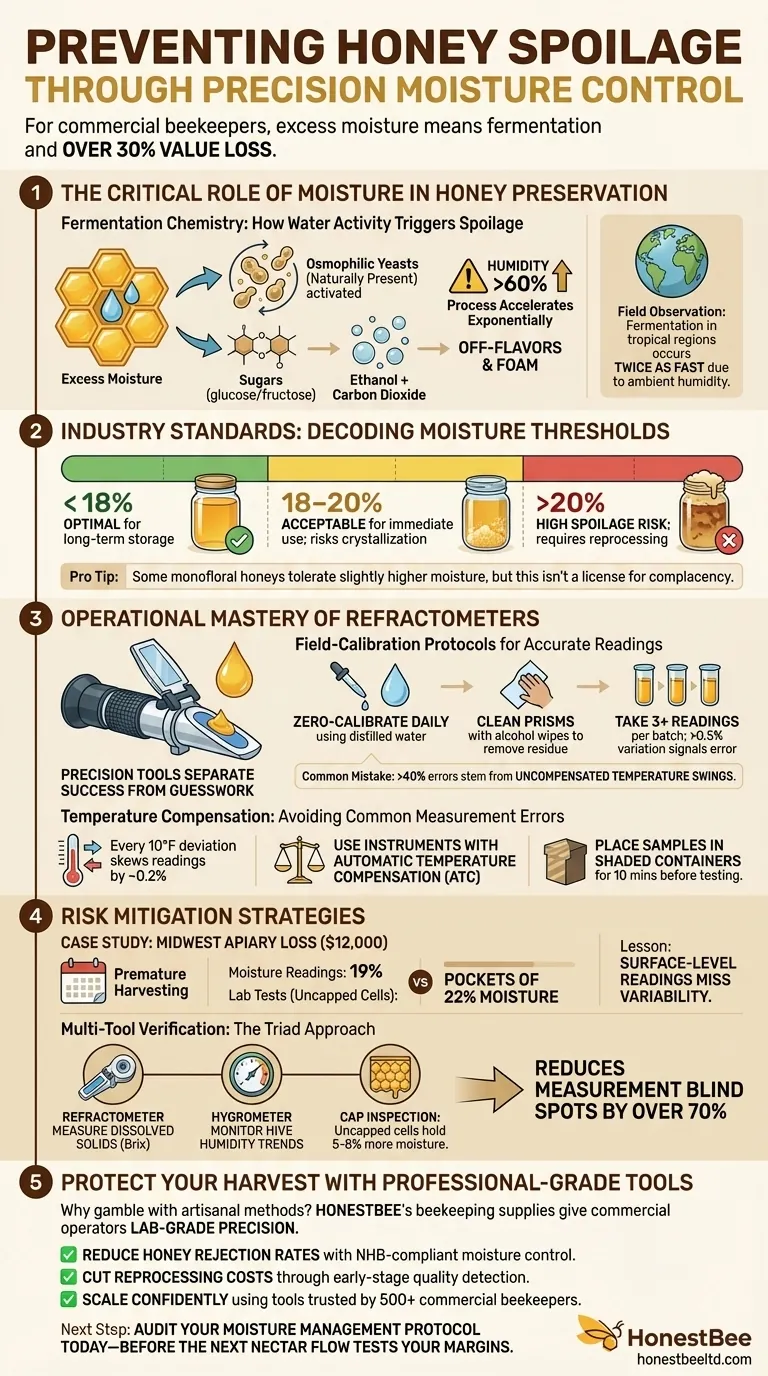

For commercial beekeepers, honey spoilage isn't just a quality issue—it's a direct threat to profitability. Research shows that improperly stored honey with excess moisture can lose over 30% of its market value due to fermentation. This guide breaks down the science of moisture control and field-tested techniques to preserve honey quality at scale.

The Critical Role of Moisture in Honey Preservation

Honey’s shelf stability hinges on one factor: keeping water activity below fermentation thresholds.

Fermentation Chemistry: How Water Activity Triggers Spoilage

When honey absorbs moisture:

- Osmophilic yeasts (naturally present in honey) activate

- Sugars convert to ethanol and carbon dioxide—creating off-flavors and foam

- The process accelerates exponentially in humidity above 60%

Field observation: Beekeepers in tropical regions report fermentation occurring twice as fast as in arid climates due to ambient humidity.

Industry Standards: Decoding 17-20% Brix Scale Thresholds

The National Honey Board’s research confirms:

- <18% moisture: Optimal for long-term storage

- 18-20%: Acceptable for immediate use but risks crystallization

- >20%: High spoilage risk; requires reprocessing

Pro Tip: Some monofloral honeys (e.g., black locust) tolerate slightly higher moisture without fermenting—but this isn’t a license for complacency.

Operational Mastery of Refractometers

Precision tools separate successful operations from guesswork.

Field-Calibration Protocols for Accurate Readings

- Zero-calibrate daily using distilled water

- Clean prisms with alcohol wipes to remove sugar residues

- Take 3+ readings per batch—variation >0.5% signals measurement errors

Common Mistake: Over 40% of refractometer errors stem from uncompensated temperature swings.

Temperature Compensation: Avoiding Common Measurement Errors

- Every 10°F deviation from calibration temp skews readings by ~0.2%

- Use instruments with automatic temperature compensation (ATC)

- Field fix: Place samples in shaded containers for 10 mins before testing

Risk Mitigation Strategies

Case Study: Financial Losses from Premature Harvesting

A Midwest apiary lost $12,000 in 2022 by harvesting frames during a humid spell. Their moisture readings showed 19%—but later lab tests revealed pockets of 22% moisture in uncapped cells.

Lesson: Surface-level readings miss variability within the hive.

Multi-Tool Verification: Combining Refractometers with Hygrometers

- Refractometers: Measure dissolved solids (Brix)

- Digital hygrometers: Monitor hive humidity trends

- Cap inspection: Uncapped cells often hold 5-8% more moisture

This triad approach reduces measurement blind spots by over 70% compared to single-tool reliance.

Protect Your Harvest With Professional-Grade Tools

Why gamble with artisanal methods when HONESTBEE’s beekeeping supplies give commercial operators lab-grade precision in the field? Our wholesale-focused equipment helps distributors and large apiaries:

✅ Reduce honey rejection rates with NHB-compliant moisture control

✅ Cut reprocessing costs through early-stage quality detection

✅ Scale confidently using tools trusted by 500+ commercial beekeepers

Next Step: Audit your moisture management protocol today—before the next nectar flow tests your margins.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Thermostatic Conical Honey Melter

- Natural Wood Honey Dipper for Tea Coffee and Desserts

- Modern Honeycomb Pattern Wooden Honey Dipper for Stirring and Drizzling

Related Articles

- Mastering Honey Refractometer Basics: A Guide to Precision and Profitability

- How to Accurately Test Honey Readiness: Science-Backed Methods for Beekeepers

- The Second Half of the Measurement: Protecting the Integrity of Your Honey Refractometer

- From Profit to Spoilage: The One Number Every Commercial Beekeeper Must Know

- From Ambiguity to Certainty: The Practical Case for Digital Honey Refractometers