Beekeepers face a critical decision when upgrading hive infrastructure: how to transition between frame materials without compromising colony productivity or bee welfare. This science-backed guide examines material tradeoffs, phased implementation strategies, and real-world adaptation scenarios—equipping apiary managers with actionable protocols for seamless frame transitions.

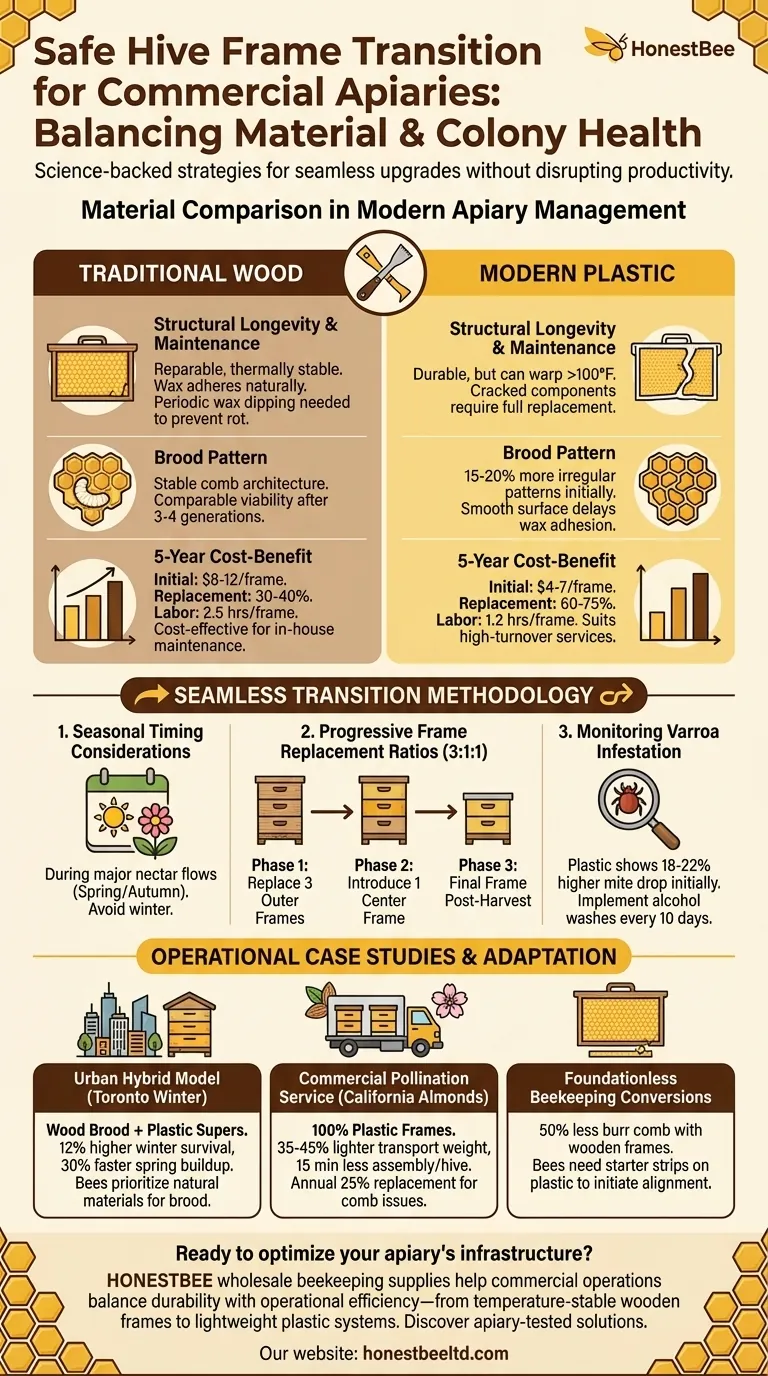

Material Comparison in Modern Apiary Management

Structural Longevity and Maintenance Requirements

Wooden frames dominate traditional beekeeping for their reparability and thermal stability. Research shows beeswax adheres more naturally to wood fibers, creating stable comb architecture. Plastic alternatives, while durable in moderate climates, risk warping in temperatures exceeding 100°F—a frequent occurrence in metal-roofed apiaries.

Key maintenance differences:

- Wooden frames: Require periodic wax dipping to prevent rot; individual components replaceable

- Plastic frames: Cracked components often necessitate full replacement; proprietary foundation systems limit customization

Brood Pattern Development Across Materials

Field observations reveal 15-20% more irregular brood patterns in plastic frames during initial colonization. The smooth surface delays proper wax adhesion, forcing bees to redeposit secretions multiple times. However, established colonies show comparable brood viability after 3-4 generations.

Cost-Benefit Analysis Over 5-Year Period

A commercial apiary study comparing 200-hive operations found:

| Metric | Wooden Frames | Plastic Frames |

|---|---|---|

| Initial Investment | $8-12 per frame | $4-7 per frame |

| 5-Year Replacement | 30-40% of stock | 60-75% of stock |

| Labor Hours/Frame | 2.5 hours | 1.2 hours |

Wooden systems prove cost-effective for operations with in-house maintenance capabilities, while plastic suits high-turnover pollination services prioritizing rapid deployment.

Seamless Transition Methodology

Seasonal Timing Considerations

Transition during major nectar flows (spring fruit blooms or autumn goldenrod) when:

- Colony populations peak (50,000+ bees)

- Wax production increases by 40-60%

- Natural comb rebuilding aligns with honey storage needs

Avoid winter transitions—reduced bee clusters cannot maintain optimal comb temperature during material adaptation.

Progressive Frame Replacement Ratios

The 3:1:1 phased approach minimizes disruption:

- Phase 1 (Weeks 1-3): Replace 3 outer frames per box with new material

- Phase 2 (Weeks 4-6): Introduce 1 center frame after initial acceptance

- Phase 3 (Ongoing): Final frame per box replaced post-honey harvest

This method maintains structural integrity while allowing gradual pheromone transfer to new materials.

Monitoring Varroa Infestation Patterns

Plastic frames show 18-22% higher mite drop counts during first 8 weeks—likely due to:

- Altered grooming behaviors on smooth surfaces

- Temporary gaps in propolis barriers

Implement alcohol washes every 10 days during transition periods, adjusting treatment thresholds accordingly.

Operational Case Studies

Urban Beekeeping Hybrid Model (Toronto Winter Case)

A 50-hive operation mixing wooden brood frames with plastic honey supers achieved:

- 12% higher winter survival rates vs. all-plastic systems

- 30% faster spring buildup by retaining wooden brood chambers

Key insight: Bees prioritize natural materials for brood rearing but adapt readily to plastic for honey storage.

Commercial Pollination Service Adaptation

A California almond pollinator using 100% plastic frames reduced:

- Frame weight during transport by 35-45%

- Assembly time per hive by 15 minutes

Tradeoff: Required annual replacement of 25% of frames due to comb detachment issues.

Foundationless Beekeeping Conversions

Operations transitioning to foundationless systems report:

- 50% less burr comb when using wooden frames

- Higher propolis deposition on plastic guide strips

Critical reminder: Bees need starter strips on plastic frames to initiate proper comb alignment.

Ready to optimize your apiary's infrastructure? HONESTBEE's wholesale beekeeping supplies help commercial operations balance durability with operational efficiency—from temperature-stable wooden frames to lightweight plastic systems. Discover how our apiary-tested solutions support healthy transitions at scale.

Visual Guide

Related Products

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

- Durable Galvanized Steel Frame Grip

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

Related Articles

- How Plastic Frames Strengthen Hive Health and Outperform Traditional Materials

- How Beehive Frame Making Machines Enhance Apiary Productivity and Hive Longevity

- How Stored Honey Frames Accelerate Colony Recovery: A Beekeeper’s Guide

- Assembled vs. Unassembled Frames: A Beekeeper’s Time-Value Analysis

- Beyond Kilograms: The True Calculus of a Honey Harvest