The Allure of a Shortcut

Imagine a beekeeper after their first successful harvest. They hold a heavy frame, dripping with a chaotic mixture of golden honey and pale wax cappings. The immediate, intuitive thought is to apply heat—to simply melt it all down on a stovetop and let it separate.

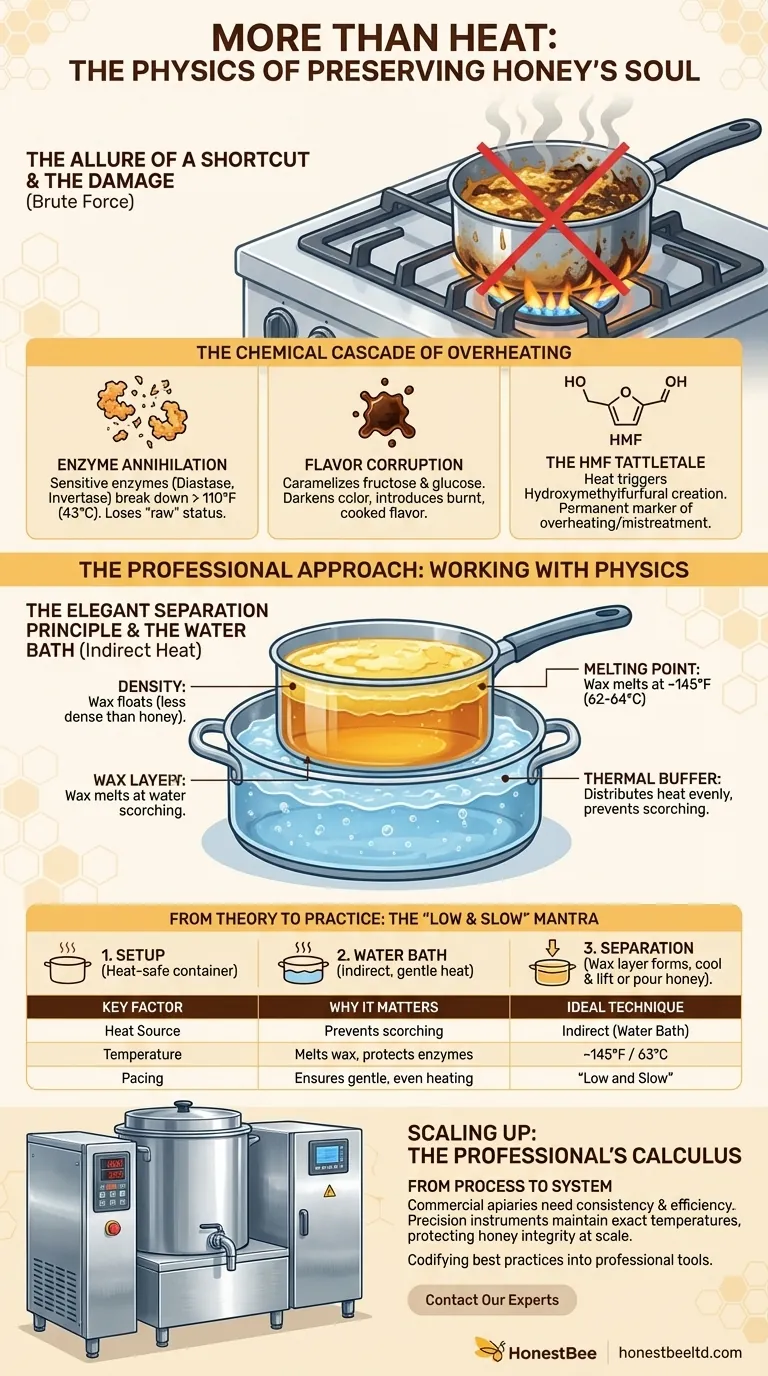

This impulse is rooted in a common psychological trap: the belief that faster and more powerful is always better. We apply this logic to cars, computers, and a hundred other things. But when dealing with a delicate biological product like honey, that instinct is destructive. It's the difference between a craftsman and a demolition crew.

The Unseen Damage of Brute Force

Applying direct, high heat to a honey-wax mixture doesn't just separate it; it permanently wounds the honey. The damage occurs on a chemical level, silently stripping away the very qualities that make it valuable.

The Chemical Cascade of Overheating

The destructive process unfolds in three distinct ways:

- Enzyme Annihilation: Raw honey is alive with beneficial enzymes like diastase and invertase. These compounds are incredibly sensitive to heat. Once temperatures climb past 110°F (43°C), these enzymes begin to break down, effectively pasteurizing the honey and erasing its "raw" status.

- Flavor Corruption: Overheating caramelizes honey's natural fructose and glucose. This chemical reaction darkens the color and introduces a generic, slightly burnt "cooked" flavor, masking the delicate and unique floral notes of its origin.

- The HMF Tattletale: Heat triggers the creation of a compound called Hydroxymethylfurfural (HMF). While not harmful in small amounts, high HMF levels are an irreversible chemical fingerprint. In the commercial world, HMF is a key marker used to identify honey that has been overheated, poorly stored, or is simply old. It's the evidence of mistreatment.

Working With Physics, Not Against It

The professional approach isn't a battle against the wax. It's an elegant process that uses the fundamental properties of the materials themselves to achieve a clean separation.

The Elegant Separation Principle

The solution lies in two simple facts of physics:

- Density: Beeswax is less dense than honey.

- Melting Point: Beeswax has a relatively low melting point, around 144-147°F (62-64°C).

By applying just enough gentle, controlled warmth to liquefy the wax, it will naturally float to the surface, forming a perfect layer above the denser, less viscous honey. The materials do the work for you.

The Water Bath: A Shield Against Chaos

The key to delivering this gentle warmth is indirect heat. A direct flame creates intense hot spots that will scorch the honey on contact.

A water bath—using a double boiler or placing your honey pot inside a larger crockpot of water—acts as a thermal buffer. It distributes the heat evenly and prevents the temperature from ever spiking to dangerous levels. It’s the difference between a controlled experiment and a fire.

From Theory to Practice: A Controlled Process

Achieving a perfect separation is straightforward when you respect the process. The mantra is "low and slow."

- Setup: Place your crushed comb or wax cappings into a heat-safe stainless steel or glass container.

- The Water Bath: Set this container inside a larger pot. Add water to the outer pot until it surrounds the bottom half of the inner one.

- Gentle Heating: Apply low heat. The goal is to slowly raise the water temperature until the wax is fully melted. Never let the water boil.

- Separation: Once a clear liquid wax layer forms on top, turn off the heat. You can either let the mixture cool completely—the wax will solidify into a hard disk you can lift off—or carefully pour the honey out from a spigot at the bottom.

| Key Factor | Why It Matters | Ideal Technique |

|---|---|---|

| Heat Source | Prevents scorching and caramelization | Indirect (Water Bath) |

| Temperature | Melts wax without damaging honey's enzymes | ~145°F / 63°C |

| Pacing | Ensures gentle, even heating | "Low and Slow" |

The Professional's Calculus: From Process to System

For a hobbyist, a simple crockpot setup is sufficient. But for commercial apiaries, where hundreds of pounds of honey must be processed, this principle must be scaled into a reliable system. Consistency, efficiency, and quality are paramount. How do you maintain that gentle, precise temperature control across large volumes?

This is where improvised solutions fall short and professional equipment becomes essential. Systems like the stainless steel tanks and dedicated wax melters supplied by HONESTBEE are not just containers; they are precision instruments. They are engineered to maintain exact temperatures, institutionalizing the "gentle heat" principle that protects the integrity of the honey. They transform a careful craft into a scalable, professional operation without compromising on quality.

Moving from a hobby to a business means codifying your best practices into your tools. For preserving the soul of your honey, the right equipment is everything. Contact Our Experts

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

Related Articles

- How to Melt Beeswax Safely: Science-Backed Protocols to Prevent Overheating and Fires

- Electric Wax Melters: How Modern Technology Enhances Efficiency and Savings

- How to Purify Beeswax Contaminated with Brood Comb: Maximizing Honey Recovery

- How to Melt Beeswax Safely: Expert Methods to Avoid Fire Risks

- How Beekeepers Turn Old Beeswax into Profitable Ventures