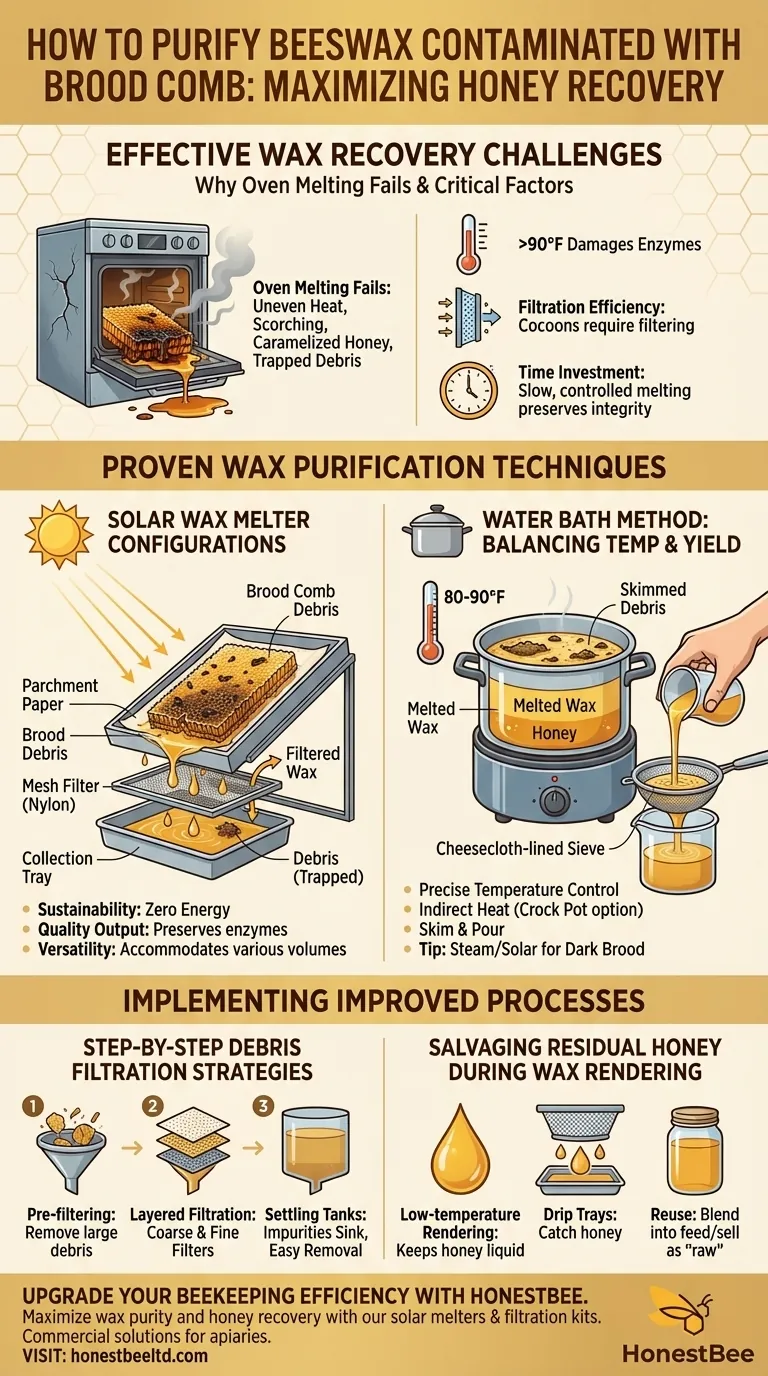

For beekeepers, efficiently purifying beeswax contaminated with brood comb debris while recovering residual honey is a common challenge. Traditional methods like oven melting often fall short, leaving behind impurities or wasting valuable honey. This guide explores advanced techniques—solar wax melters and water bath methods—to achieve cleaner wax and higher honey yields.

Effective Wax Recovery Challenges

Why Oven Melting Fails with Brood Comb Contamination

Oven melting, while straightforward, struggles with brood comb due to uneven heat distribution. High temperatures can scorch wax, degrade enzymes, and trap debris, reducing quality. Additionally, honey residues often caramelize, making recovery impossible.

Critical Factors in Wax-Honey Separation

Successful separation hinges on:

- Temperature control: Excessive heat (>90°F) damages wax enzymes and honey flavor.

- Filtration efficiency: Non-melting debris (e.g., cocoons) requires multi-stage filtering.

- Time investment: Slow, controlled melting preserves wax integrity.

Proven Wax Purification Techniques

Solar Wax Melter Configurations for Debris-Rich Wax

Solar wax melters leverage sunlight to gently melt wax, ideal for contaminated brood comb.

Advantages:

- Sustainability: Zero energy costs; fully solar-powered.

- Quality output: Slow melting preserves wax enzymes and honey residues.

- Versatility: Stainless steel models accommodate various hive systems and wax volumes.

Best Practices:

- Layer comb between parchment paper to prevent debris mixing.

- Angle the melter to direct filtered wax into a collection tray.

- Use a secondary mesh filter (e.g., nylon) to catch fine particles.

Water Bath Method: Balancing Temperature and Yield

A water bath (or double boiler) offers precise temperature control for delicate wax.

Steps:

- Heat water to 80–90°F—warm enough to melt wax but protect honey.

- Use a crock pot for indirect heat if stove monitoring is impractical.

- Skim floating debris; pour liquid wax through a cheesecloth-lined sieve.

Tip: Dark brood wax can be recycled by steaming or solar remelting to remove impurities.

Implementing Improved Processes

Step-by-Step Debris Filtration Strategies

- Pre-filtering: Remove large debris (e.g., wood splinters) before melting.

- Layered filtration: Combine coarse (metal mesh) and fine (nylon) filters.

- Settling tanks: Let melted wax cool slightly; impurities sink for easy removal.

Salvaging Residual Honey During Wax Rendering

- Low-temperature rendering: Keeps honey liquid for separation.

- Drip trays: Place under filtered wax to catch honey droplets.

- Reuse: Blend recovered honey into feed supplements or sell as "raw" byproduct.

Upgrade Your Beekeeping Efficiency with HONESTBEE

Maximize wax purity and honey recovery with HONESTBEE’s solar melters and filtration kits—designed for commercial apiaries and distributors. Explore our wholesale-focused solutions to streamline your rendering process today.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

Related Articles

- How Beekeepers Turn Wax Cappings From Waste to Profit

- How to Melt Beeswax Safely: Expert Methods to Avoid Fire Risks

- The Beekeeper's Paradox: Why Slow Heat Unlocks the True Value of Beeswax

- How to Melt Beeswax Safely: Science-Backed Protocols to Prevent Overheating and Fires

- The Unseen Engine of the Hive: Decoding the Economics of Wax Production