Modern beekeeping demands precision, efficiency, and durability—qualities the Beehive Frame Machine delivers through integrated automation and engineering. This article explores how its multi-process synergy elevates apiculture manufacturing, reduces operational costs, and scales seamlessly for commercial apiaries.

Optimized Workflow for Apiculture Frame Manufacturing

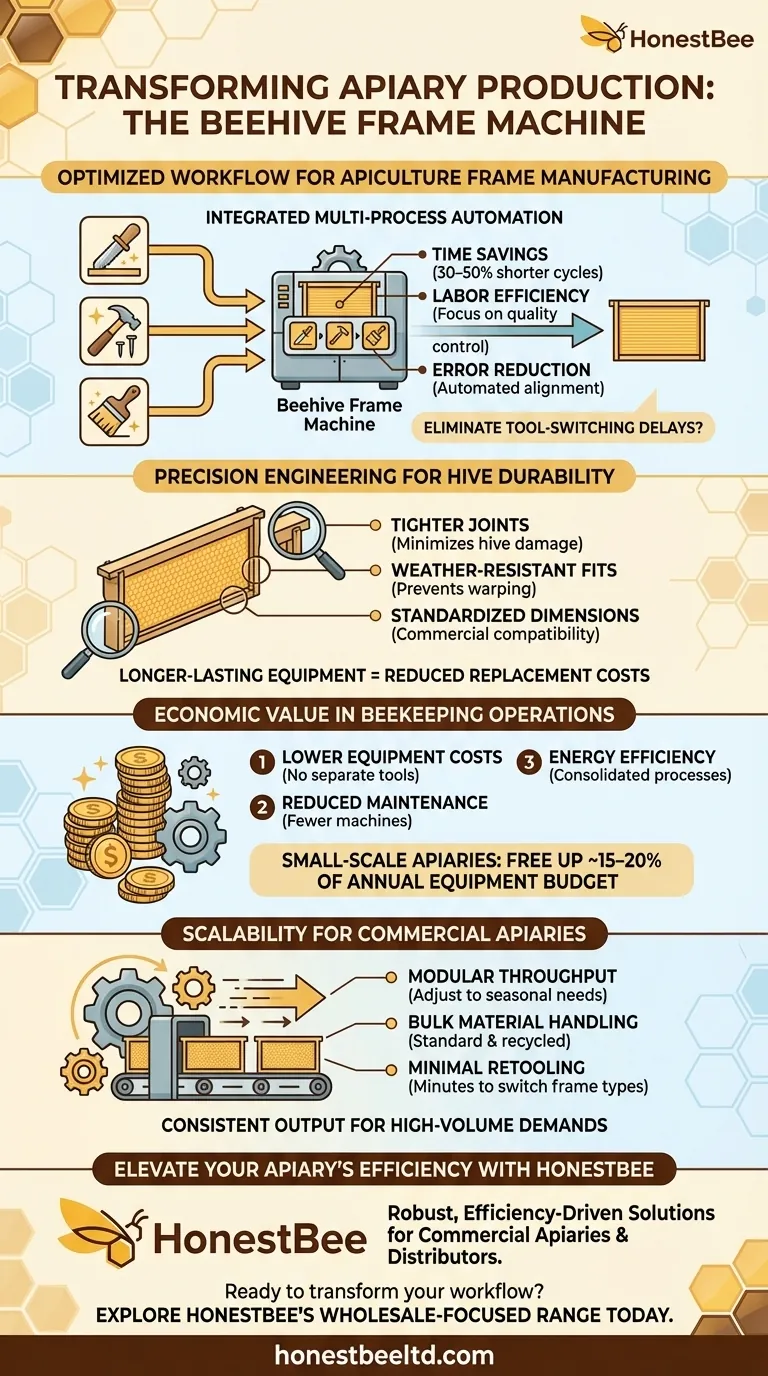

Integrated Multi-Process Automation

The Beehive Frame Machine consolidates cutting, assembly, and finishing into a single automated workflow. Traditional methods require separate tools for each step, creating bottlenecks and inconsistency. By unifying these processes:

- Time savings: Production cycles shorten by roughly 30–50% compared to manual methods.

- Labor efficiency: Reduces the need for specialized operators, allowing staff to focus on quality control.

- Error reduction: Automated alignment ensures every frame meets exact specifications.

Have you considered how eliminating tool-switching delays could streamline your apiary’s output?

Precision Engineering for Hive Durability

Durability begins with design. The machine produce frames with:

- Tighter joints: Minimizes hive damage during inspections or transport.

- Weather-resistant fits: Prevents warping in humid climates.

- Standardized dimensions: Ensures compatibility with commercial hive systems.

This precision translates to longer-lasting equipment, reducing replacement costs for beekeepers.

Economic Value in Beekeeping Operations

Cost Reduction Through Tool Consolidation

Replacing multiple devices with one machine cuts expenses in three ways:

- Lower equipment costs: No need to purchase separate cutting or assembly tools.

- Reduced maintenance: Fewer machines mean fewer parts to service.

- Energy efficiency: Consolidated processes consume less power than running standalone units.

For small-scale apiaries, this consolidation can free up roughly 15–20% of the annual equipment budget.

Scalability for Commercial Apiaries

The Beehive Frame Machine adapts to high-volume demands:

- Modular throughput: Adjust production speed to meet seasonal needs.

- Bulk material handling: Processes standard lumber or recycled materials efficiently.

- Minimal retooling: Switches between frame types (e.g., deep vs. medium) in minutes.

Large operations benefit from consistent output—whether producing hundreds of frames weekly or scaling for regional distribution.

Elevate Your Apiary’s Efficiency with HONESTBEE

The Beehive Frame Machine isn’t just a tool; it’s a strategic upgrade for beekeepers prioritizing quality and growth. HONESTBEE equips commercial apiaries and distributors with robust, efficiency-driven solutions—ensuring your operation stays ahead in a competitive market.

Ready to transform your beekeeping equipment workflow? Explore HONESTBEE’s wholesale-focused range today.

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- HONESTBEE Top Bar & Bottom Bar Forming Machine | Bee Frame Machine

Related Articles

- How to Make Bee Frames in a Factory: The Ultimate Guide to High-Volume Production with HONESTBEE Bee Frame Machines

- Unlock Self-Sufficiency: The HONESTBEE Semi-Automatic Bee Frame Machine – Your All-in-One Workshop Solution

- Revolutionize Your Workshop: The Ultimate Bee Frame Side Bar Forming Machine for Unmatched Efficiency & Customization

- How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges

- Unlock Peak Efficiency: The HONESTBEE Bee Frame Machine for Flawless Frame Assembly