It's one of the most frustrating moments for a commercial beekeeper. Your hives are thriving, the nectar flow was strong, and you’ve invested countless hours ensuring your bees are healthy. Yet, when it comes to the harvest, your production numbers aren't scaling as you expected. You watch as other apiaries seem to fill orders effortlessly, while you’re stuck in a cycle of slow, labor-intensive extraction, wondering where the bottleneck is. Is it your process? Your team? Or is it something more fundamental?

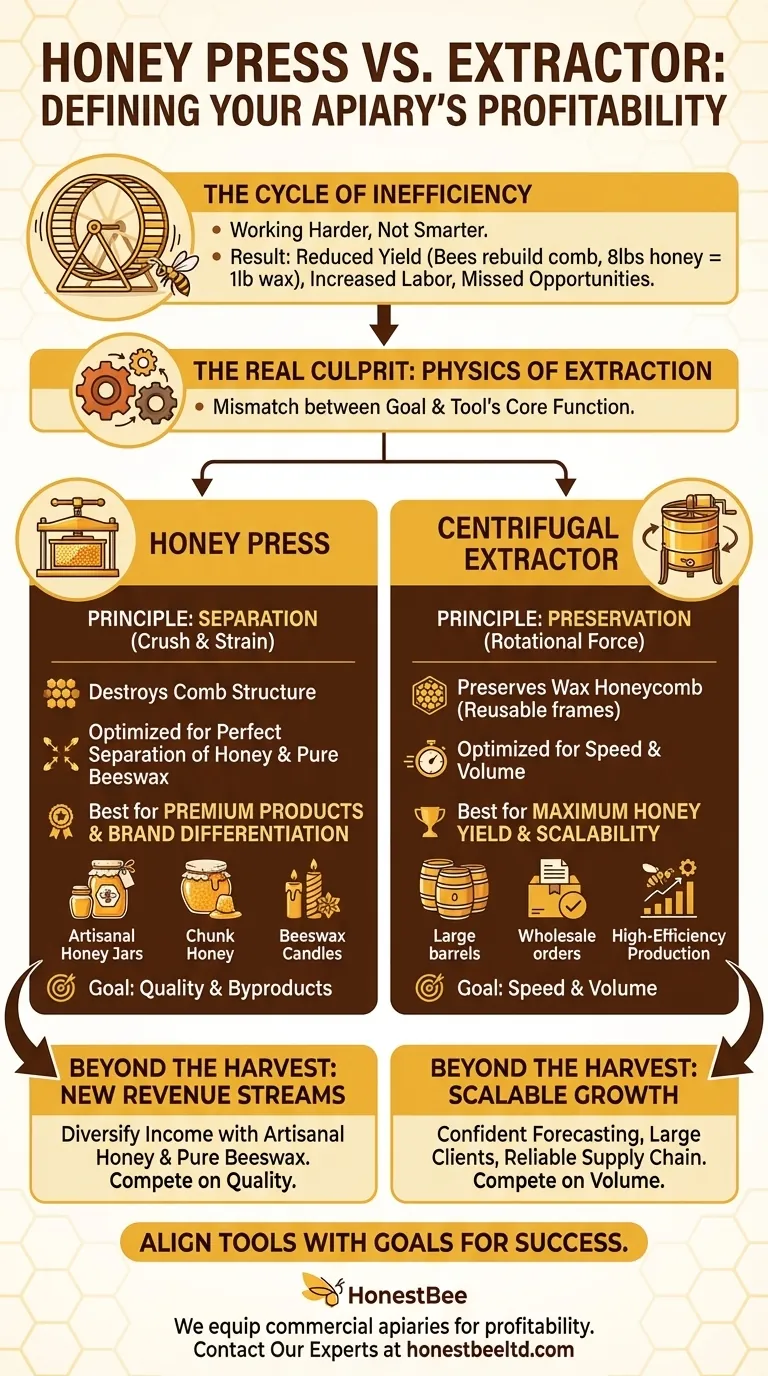

The Cycle of Inefficiency: Working Harder, Not Smarter

This isn't an uncommon struggle. Many apiaries, in an effort to increase output, simply try to push their existing equipment harder. They might run their centrifugal extractor at a higher speed, only to find they're blowing out and destroying precious comb that now needs to be rebuilt by the bees. Or, they invest in a honey press for its simplicity, only to discover their bees are spending weeks rebuilding comb instead of making more honey, severely hampering the next harvest.

These "solutions" only address the symptoms, not the cause. The business consequences are real and damaging:

- Reduced Honey Yield: Forcing bees to constantly rebuild comb is a massive energy drain. Bees consume about eight pounds of honey to produce just one pound of wax. That's honey that could have gone into a jar.

- Increased Labor Costs: Damaged equipment and inefficient processes mean more man-hours spent on cleanup, repair, and a slower extraction rate per frame.

- Missed Opportunities: When your production is unpredictable, you can't confidently commit to large wholesale orders. This limits your growth and can damage your reputation as a reliable supplier.

You're caught in a loop: working harder during the harvest only to find you're falling further behind for the next one.

The Real Culprit: It's Not Your Bees, It's the Physics of Extraction

The turning point comes when you stop asking "How can I extract faster?" and start asking "What is my extraction method actually designed to do?" The bottleneck isn't your effort; it’s a fundamental mismatch between your business goal and your equipment's core function.

The choice between a honey press and a centrifugal extractor isn't a simple matter of preference. It's a choice between two entirely different physical principles with direct business outcomes.

The Principle of Preservation: Centrifugal Extraction

A centrifugal extractor uses rotational force to sling honey out of the cells. Its entire design is optimized for one primary goal: to preserve the wax honeycomb. An intact comb can be returned to the hive, giving the bees a massive head start on the next honey flow. This method is built for speed and volume.

The Principle of Separation: The Honey Press

A honey press, through its "crush and strain" method, applies pressure to physically squeeze the honey out. This process inherently destroys the comb's structure. Its design is optimized not for comb preservation, but for a perfect separation of honey and pure beeswax. This method is built for quality and byproducts.

The "common struggles" mentioned earlier fail because they fight against these core principles. Speeding up an extractor to the breaking point negates its core benefit of preservation. Trying to rush the pressing process won't magically make the comb reusable. The problem was never the tool itself, but choosing a tool designed for one outcome while expecting another.

Aligning Your Tools with Your Goals: The Right Equipment for the Job

To truly solve this problem, you need to equip your operation based on its primary business model. It's about choosing the tool that directly enables your strategy.

For Maximum Honey Yield and Scalability

If your business is built on volume—supplying distributors, fulfilling large orders, and maximizing pounds of honey per hive—then comb reuse is non-negotiable. You need a tool designed explicitly to preserve that comb. This is where a durable, efficient centrifugal extractor becomes the cornerstone of your operation. It directly solves the root cause of production lag by eliminating the need for bees to rebuild, turning your apiary into a high-efficiency honey production engine.

For Premium Products and Brand Differentiation

If your goal is to create high-margin products—artisanal honey with unique floral notes, coveted chunk honey, and pure, high-quality beeswax for cosmetics or candles—then perfect separation is your priority. A honey press is the ideal instrument for this. It is designed to yield pristine beeswax and allows you to capture the distinct character of honey from individual combs, turning your harvest into a premium, value-added product line.

Beyond the Harvest: Unlocking New Revenue Streams for Your Apiary

When you align your equipment with your business strategy, you don't just fix a bottleneck; you open up entirely new possibilities.

With the right high-capacity extractors, you can move from struggling to meet demand to confidently forecasting your output, taking on larger clients, and scaling your operation predictably. You become a reliable powerhouse in the honey supply chain.

With a high-quality honey press, you diversify your income streams beyond bulk honey. You can build a premium brand around unique, single-source honeys and tap into the lucrative market for pure beeswax. You stop competing solely on price and start competing on quality and uniqueness.

Ultimately, choosing the right equipment isn't just a technical decision; it's the most important strategic decision you'll make for the profitability and future of your apiary.

Whether your strategy is built on maximizing volume or cultivating premium quality, having the right partner is critical. At HONESTBEE, we don't just sell equipment; we equip commercial apiaries and distributors for success by providing the specific tools that align with their business goals. Let our team help you analyze your operational needs and build a more profitable, efficient, and scalable business. To discuss your unique project and see how our wholesale-focused solutions can help you thrive, Contact Our Experts.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

Related Articles

- The Extractor's Edge: Why Preserving Comb is the Key to Apiary Profitability

- How to Choose the Right Honey Extractor for Your Beekeeping Scale

- Tangential vs Radial Honey Extractors: How to Choose for Your Beekeeping Needs

- How to Choose the Right Honey Extraction Method for Your Beekeeping Needs

- How to Optimize Centrifugal Honey Extraction for Different Hive Types