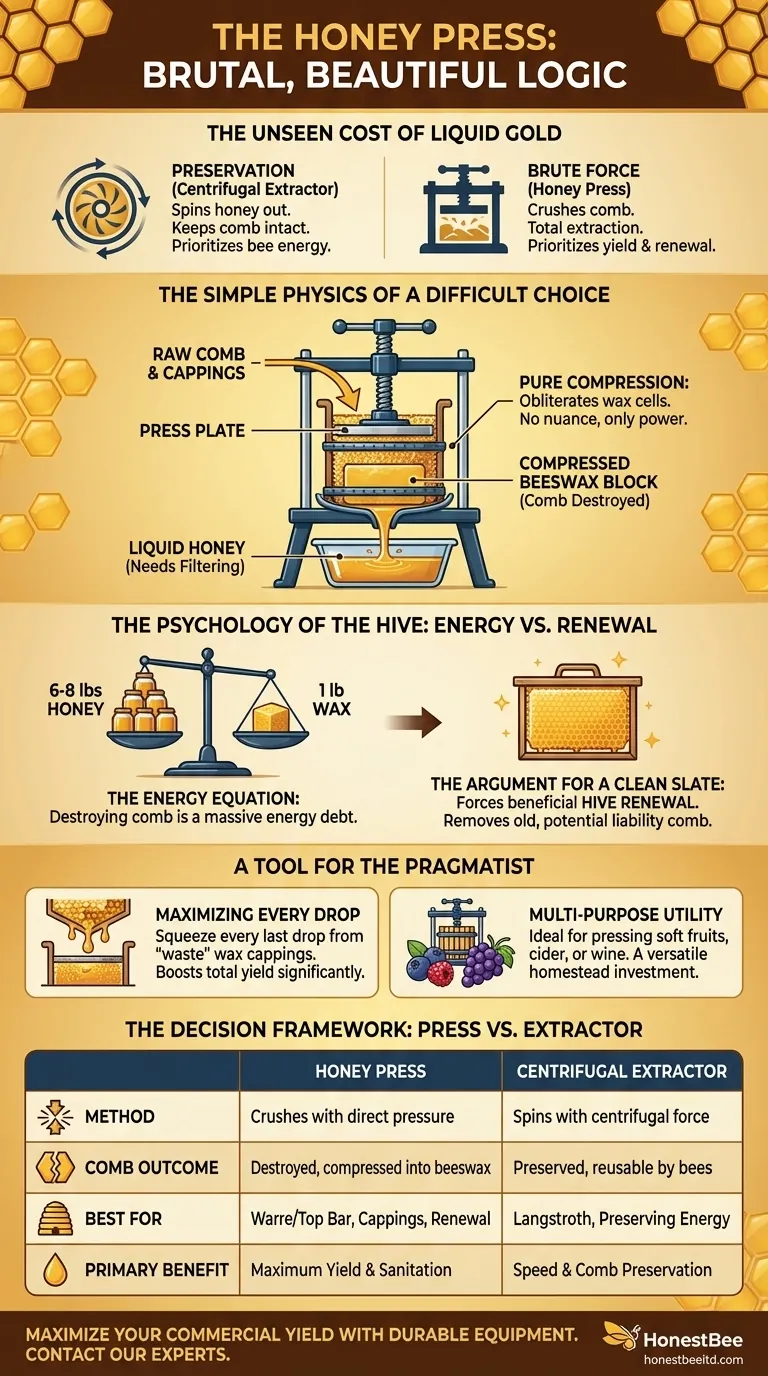

The Unseen Cost of Liquid Gold

Imagine holding a frame of honeycomb. It’s warm from the hive, heavy with honey, and perfect in its hexagonal geometry. This isn't just a container for a sweet product; it's an architectural marvel, an energy bank built by thousands of bees.

The central question every beekeeper faces is how to get the honey out. And hidden within that question is a profound choice about cost—not in dollars, but in energy.

There are two philosophies. One prizes preservation, using centrifugal force to spin honey out while keeping the delicate wax comb intact.

The other is far more direct. It prizes total extraction through brute force. This is the world of the honey press.

The Simple Physics of a Difficult Choice

A honey press operates on a principle of beautiful simplicity. It crushes the honeycomb to separate the honey from the wax. Understanding this mechanism is key to understanding its place in an apiary.

A Matter of Pure Compression

The process is mechanical and direct. Raw honeycomb, wax cappings, or burr comb are placed into a perforated basket. A press plate descends, usually driven by a heavy-duty screw, applying immense pressure.

This force obliterates the individual wax cells, rupturing them and releasing the honey. There is no nuance, only power.

What's Left Behind

The liquid honey flows through the perforations and collects in a basin below. It will be full of wax particles and debris, requiring careful filtering to become the clear, golden product we recognize.

Left behind in the basket is a dense, compressed block of beeswax. The intricate structure the bees worked so hard to build is gone forever. This outcome is not a side effect; it is the entire point.

The Psychology of the Hive: Energy vs. Renewal

The decision to use a press is less about mechanics and more about hive economics and philosophy. You are making a choice that directly impacts the energy reserves of your colony.

The Energy Equation

Bees expend a tremendous amount of energy to produce wax. It is estimated that they consume six to eight pounds of honey to secrete just one pound of wax. Drawing that wax into perfect comb costs even more.

Destroying the comb is like demolishing a factory that your workers just spent a third of their resources to build. They must now start over, diverting energy that could have been used for foraging, raising brood, or surviving winter.

The Argument for a Clean Slate

But destruction isn't always a negative. Old comb can accumulate pesticides and disease spores over time. It can become a liability for the colony's health.

Using a press forces a cycle of renewal. By systematically removing old comb, you are performing a "controlled burn" for the hive, ensuring the bees are always building on a fresh, clean foundation. For a commercial apiary focused on hive health and productivity, this is a powerful management tool.

A Tool for the Pragmatist

The honey press finds its home with beekeepers who are pragmatists, focused on efficiency, specific hive types, or multi-purpose utility.

Maximizing Every Drop

One of its most critical applications is processing wax cappings. When you uncap a frame to extract honey, those wax lids are saturated with the harvest's best honey. Throwing them away is wasteful.

A honey press allows you to squeeze every last drop from this "waste" product, significantly boosting your total yield. For a commercial operation, this reclaimed honey translates directly to the bottom line. It's the difference between a good harvest and a great one.

The Homesteader's Advantage

The simple, robust design of a press gives it value far beyond the apiary. The same mechanism used to crush honeycomb is perfectly suited to press juice from soft fruits, berries, or grapes. It can serve as a fruit press, a cider press, or a wine press. This versatility makes it an incredibly sound investment for a small farm or homestead.

The Decision Framework: Press vs. Extractor

The choice is not about which tool is "better," but which is the right tool for your specific goal. A professional operation understands that different tasks require different equipment.

| Feature | Honey Press | Centrifugal Extractor |

|---|---|---|

| Method | Crushes comb with direct pressure | Spins honey out with centrifugal force |

| Comb Outcome | Destroyed and compressed into beeswax | Preserved and reusable by the bees |

| Best For | Warre/Top Bar hives, wax cappings, hive renewal | Langstroth hives, preserving bee energy |

| Primary Benefit | Maximum honey yield and hive sanitation | Speed and comb preservation |

| Additional Uses | Excellent for pressing fruit, berries, and grapes | None |

For large-scale commercial apiaries and beekeeping equipment distributors, efficiency, durability, and yield are paramount. A high-quality honey press isn't just an alternative; it's a strategic asset for maximizing returns and maintaining hive health. HONESTBEE specializes in supplying this type of robust, wholesale beekeeping equipment, built to withstand the demands of commercial use.

If your operation is ready to maximize its yield with durable, reliable equipment built for the task, Contact Our Experts.

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Stainless Steel Honey Press Wax Press with Tank

Related Articles

- How to Optimize Centrifugal Honey Extraction for Different Hive Types

- How Honey Screw Presses Deliver Higher Yields With Less Waste

- Electric Wax Melters: How Modern Technology Enhances Efficiency and Savings

- The Last Drop: Maximizing Yield and Purity with a Stainless Steel Honey Press

- Beyond the Extractor: How Honey Presses Turn Waste into Profit for Commercial Apiaries