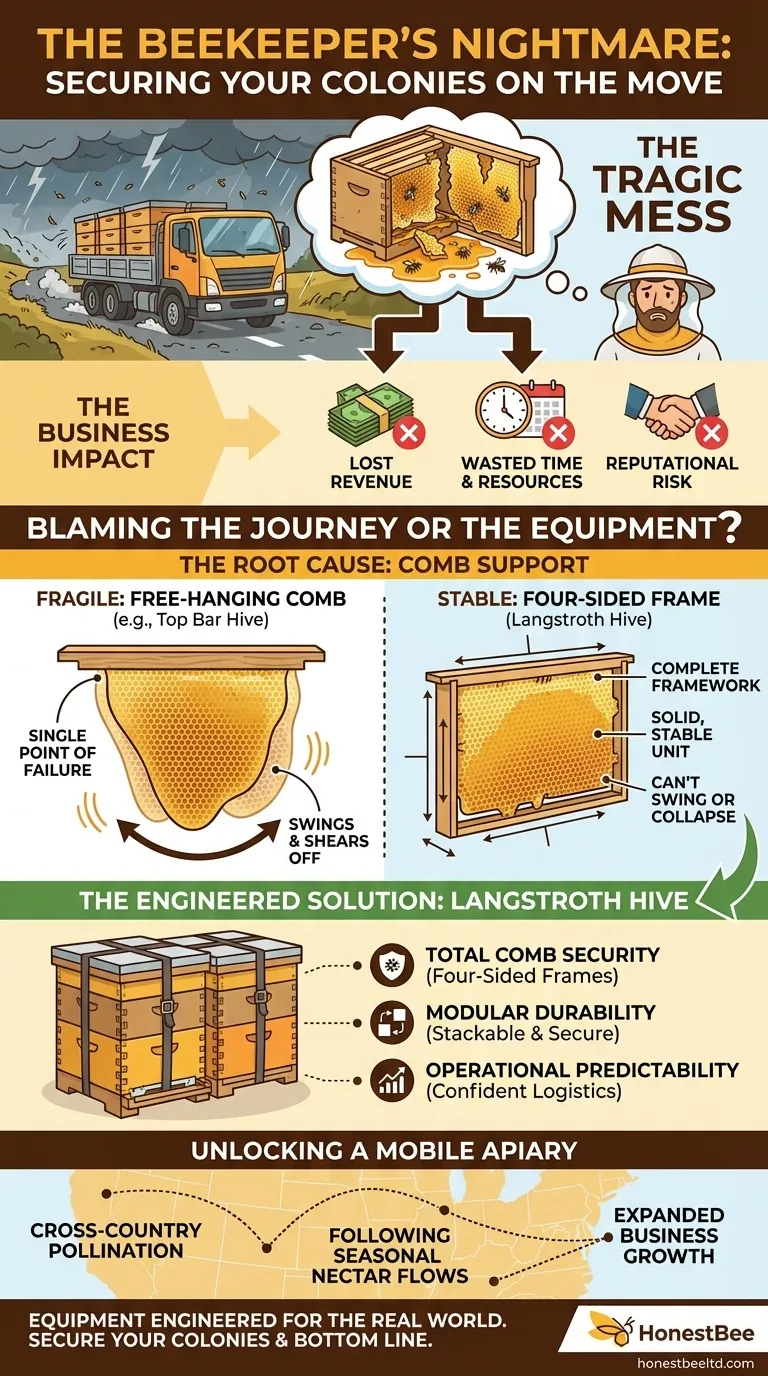

It’s a scenario that keeps commercial beekeepers up at night. You’ve spent months nurturing a strong colony, and now it's time to move it for a lucrative pollination contract or to a new nectar flow. But when you arrive and open the hive, you’re met with a scene of absolute devastation: a sticky, tragic mess of broken comb, spilled honey, and crushed bees. The entire colony, a source of future profit, is a total loss.

If this has happened to you, you’re not alone. And it’s not because you hit a pothole or took a corner too fast.

The Common Struggle: Blaming the Journey, Not the Equipment

When a hive move goes wrong, most beekeepers blame external factors. We tell ourselves we need to drive slower, add more padding, or find a smoother route. We invest time and effort into treating our hives like fragile glass, hoping for the best but fearing the worst.

This approach, however, is a gamble. And for a commercial operation, gambling is bad for business. Every lost colony represents:

- Lost Revenue: A direct hit to your honey production and pollination service income.

- Wasted Time & Resources: Months of labor and investment are wiped out in an instant.

- Reputational Risk: Failing to deliver healthy hives for pollination can damage your standing with farmers and clients.

The constant anxiety and unpredictable losses make it nearly impossible to scale an operation reliably. But what if the problem isn't the journey at all? What if the root cause is built directly into the hive itself?

The Root of the Problem: A Single Point of Failure

The difference between a successful move and a catastrophic failure comes down to a fundamental principle of structural engineering: how the honeycomb is supported.

The Fragility of Free-Hanging Comb

In some hive designs, like top bar hives, the bees build their comb downwards from a single wooden bar. Imagine a heavy, wax-and-honey-filled curtain hanging from a single rod. This structure is only attached at the very top. It has no side or bottom support.

During transport, every bump, tilt, and vibration causes this heavy comb to swing. A sudden jolt is all it takes for the wax to shear off the top bar, collapsing onto the bees and brood below. The "solutions" of driving carefully are just attempts to manage a fundamentally unstable design—they don't solve the core problem.

The Stability of a Four-Sided Frame

Now, consider the design of a Langstroth hive. Here, the bees build their comb inside a rigid, four-sided frame, like a painting secured in its frame. The comb is attached and supported on all sides—top, bottom, left, and right.

This complete framework makes the entire comb a solid, stable unit. It can’t swing, shear, or collapse. It’s a design built from the ground up to withstand the exact forces of movement and transport. The hive isn't fragile; it's a durable, modular piece of equipment.

The Solution Embodied: Equipment Engineered for the Real World

To eliminate the risk of transport disaster, you don’t need a better truck; you need a better hive. You need a system specifically engineered for the demands of a mobile, commercial apiary.

This is precisely why the Langstroth hive has become the global standard for professional beekeeping. Its design isn't an accident; it's a direct solution to the physical problem of comb instability. HONESTBEE specializes in providing these robust, professional-grade Langstroth hives and components because we understand that for a business, reliability isn't a feature—it's a requirement.

Our equipment directly addresses the root cause of transport failure by ensuring:

- Total Comb Security: The four-sided frames lock each comb in place, transforming a fragile liability into a secure asset.

- Modular Durability: The standardized boxes are designed to be stacked, strapped, and moved efficiently and safely, time and time again.

- Operational Predictability: You can plan your logistics and meet your contracts with confidence, knowing your equipment is built for the job.

Beyond the Fix: Unlocking a Truly Mobile Apiary

When you stop worrying about hives collapsing, you unlock a new level of operational freedom and profitability. With a fleet of reliable, easy-to-move Langstroth hives, your business can achieve what was previously too risky or impractical.

You can confidently pursue cross-country pollination contracts, which are often the most lucrative. You can strategically move your apiaries to follow seasonal nectar flows, dramatically increasing your honey yields. You can expand your business, manage your colonies with greater efficiency, and build a more resilient and profitable operation. The solution to a simple physics problem becomes the key to your business growth.

Your business depends on healthy, productive colonies that can be deployed where they are needed most. Don't let equipment with a built-in point of failure undermine your hard work and limit your potential. Our team understands the logistical challenges of large-scale beekeeping and is dedicated to supplying the durable, reliable equipment you need to succeed. Let's discuss how the right hardware can secure your colonies and your bottom line. Contact Our Experts.

Visual Guide

Related Products

- Langstroth Bee Hives Bee Keeping Box for Beginners Beekeeping

- Metal Bee Hive Stand Bee Box Stand for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Professional Grade Foldable Beehive Handles

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

Related Articles

- The Weight of Survival: Why Winter Beekeeping is a Test of Restraint

- How Medium Boxes Elevate Beekeeping Efficiency: Ergonomics, Hive Health & Cost Savings

- How to Choose Between Top Bar and Langstroth Hives for Effortless Beekeeping

- Comprehensive Guide to Attracting Bees to a Hive

- How Medium Boxes Make Beekeeping Easier While Protecting Your Hives