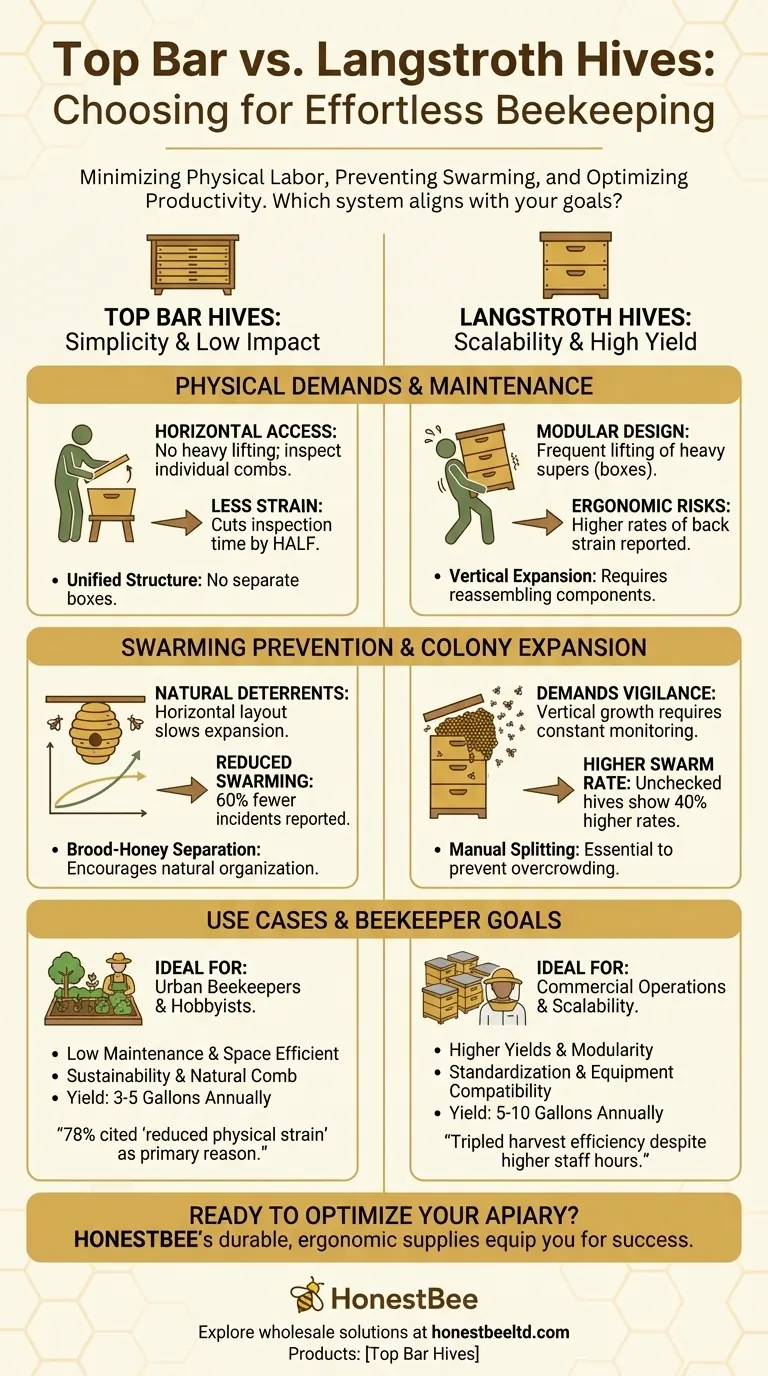

Beekeepers seeking to minimize physical labor while maintaining colony health and productivity face a critical choice: Top Bar or Langstroth hives? Each system offers distinct advantages in ergonomics, swarming prevention, and scalability. This guide compares their workflows through real-world case studies, helping you align hive selection with your beekeeping goals.

Comparing Physical Demands and Maintenance Workflows

Ergonomic Risks of Langstroth Box Management

Langstroth hives demand significant physical effort due to their modular design. Beekeepers must routinely:

- Lift heavy supers (boxes) during inspections or honey harvests

- Reassemble multiple components (frames, queen excluders, covers)

- Monitor and add boxes as colonies expand

Research shows that commercial beekeepers using Langstroth systems report higher rates of back strain from repeated lifting. The design’s vertical expansion also requires frequent checks to prevent overcrowding—a key swarming trigger.

Top Bar Hive Simplicity: When Less Is More

Top bar hives reduce labor through:

- Horizontal access: No heavy lifting; combs are inspected individually

- Unified structure: No separate boxes or frames to manage

- Natural comb building: Bees create wax without foundation sheets

Urban beekeepers and hobbyists often prefer this system, as it cuts inspection time by half compared to Langstroth setups. The trade-off? Lower honey yields (3–5 gallons annually vs. Langstroth’s 5–10 gallons), making it less ideal for large-scale operations.

Swarming Prevention and Colony Expansion

Why Langstroth Hives Demand Vigilance

Langstroth colonies grow vertically, requiring beekeepers to:

- Add supers before bees fill 70% of available space

- Monitor brood patterns to anticipate swarming urges

- Split overcrowded colonies manually

Failure to act quickly often leads to swarming losses. One study noted that Langstroth hives left unchecked for 10 days had a 40% higher swarming rate than top bar equivalents.

Top Bar Design’s Natural Swarming Deterrents

The horizontal layout of top bar hives inherently discourages swarming by:

- Slowing colony expansion: Bees build comb linearly, delaying overcrowding

- Encouraging brood-honey separation: Queens typically occupy the first 10–15 bars, leaving the rest for honey storage

- Reducing comb disruption: Inspections don’t require dismantling the hive

Beekeepers report 60% fewer swarming incidents with top bar systems, though this comes with limited scalability—colonies can’t expand beyond the hive’s fixed length.

Long-Term Beekeeper Case Studies

Urban Beekeepers Favoring Top Bar Systems

Small-scale beekeepers in cities prioritize:

- Low maintenance: Top bar hives need

- Space efficiency: Fit easily in rooftops or small yards

- Sustainability: Natural comb building aligns with organic practices

A 3-year survey of urban apiaries found that 78% of top bar users cited "reduced physical strain" as their primary reason for sticking with the system.

Commercial Apiaries Leveraging Langstroth Scalability

Large operations choose Langstroth hives for:

- Higher yields: Essential for profit margins

- Modularity: Stackable boxes allow rapid colony expansion

- Standardization: Compatibility with extractors and other equipment

One commercial beekeeper managing 200+ hives noted that Langstroth systems tripled harvest efficiency despite requiring 2–3 more staff hours per hive weekly.

Ready to Optimize Your Apiary?

Whether you’re a hobbyist prioritizing ease or a commercial producer scaling up, HONESTBEE’s beekeeping supplies equip you with durable, ergonomic solutions. Explore our wholesale-focused inventory to find hive components that match your labor and productivity goals.

Products You Might Be Looking For:

Explore low-maintenance Top Bar hives

Visual Guide

Related Products

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Professional Engraved Round Hive Number Tags for Beekeeping

Related Articles

- The Hive Tool as a Second Nature: Mastering the Micro-Movements of Beekeeping

- How to Choose Between Red and Orange J-Hook Hive Tools for Beekeeping Efficiency

- How to Choose the Best Beehive Type for Your Climate and Terrain

- How to Choose the Right Hive Tool for Your Beekeeping Needs

- The Essential Guide to Hive Tools in Modern Beekeeping