The Harvest Day Equation

Imagine the scene: hundreds of heavy frames, rich with honey, stacked and waiting. The air is thick with the scent of beeswax and nectar. This is the moment of truth for any beekeeping operation, where months of hard work are converted into a tangible product.

But between the hive and the bottle lies a critical bottleneck: extraction.

The efficiency of this single process dictates the pace of the entire operation. It's a physical problem that quickly becomes an economic one. The central question isn't just how to get the honey out, but how to do so with the least amount of time, labor, and damage to your valuable combs. The answer lies in the simple, yet profound, physics of the honey extractor.

The Geometry of Force

At its heart, a honey extractor is a centrifuge. But the difference between a tool for a hobbyist and a machine for a commercial apiary lies in a single variable: the orientation of the frame. This geometric distinction changes everything.

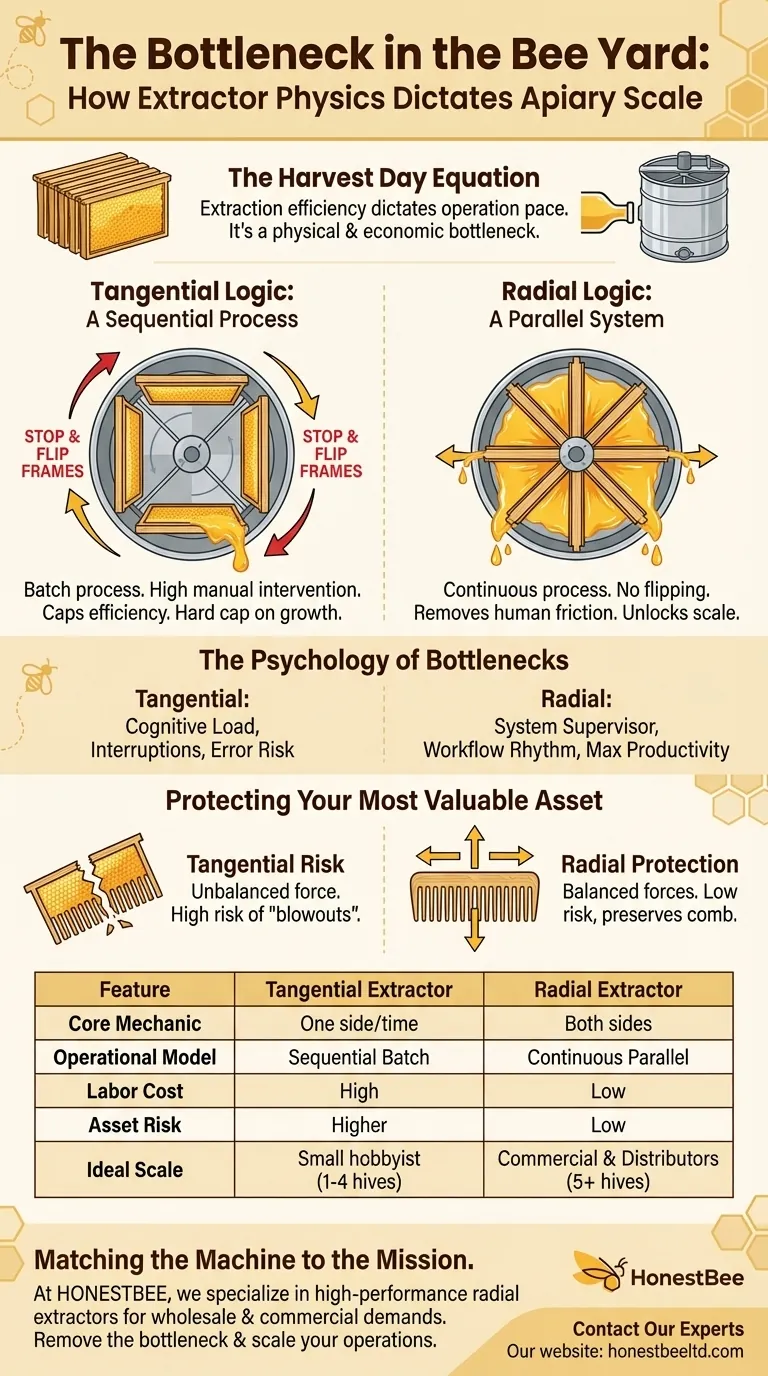

Tangential Logic: A Sequential Process

A tangential extractor positions frames with one flat side facing the outer wall. Think of a passenger pinned against the wall of a spinning carnival ride.

When the machine spins, centrifugal force pulls honey from the outward-facing cells only. To harvest the other side, the process must stop. Each frame must be manually removed, flipped, and re-inserted.

This is a batch process. It's simple, and for a handful of hives, it's perfectly manageable. But it introduces a hard cap on efficiency, dictated entirely by manual intervention.

Radial Logic: A Parallel System

A radial extractor arranges frames like the spokes of a wheel, with the top bar facing outward. This is an act of mechanical elegance.

As the drum spins, the slight upward angle of a bee's honeycomb cell aligns perfectly with the force vectors. Honey is pulled from both sides of the frame simultaneously.

There is no need to stop. There is no need to flip frames. The process is continuous, removing the primary point of human friction from the system.

The Psychology of Bottlenecks

The cost of the tangential method isn't just the time spent flipping frames. That's the obvious cost. The hidden costs are often more significant.

Manual intervention introduces cognitive load and interruption. It breaks the rhythm of the workflow. Each stop-and-flip cycle is a chance for error, fatigue, or distraction. For a commercial operation, where time is money, these micro-interruptions compound into hours of lost productivity.

A radial extractor transforms the operator's role from a manual laborer into a system supervisor. The focus shifts from flipping frames to managing the flow of the entire harvest. This is the key to unlocking scale.

Protecting Your Most Valuable Asset

Beyond labor, there is the question of asset integrity. A well-drawn comb is a masterpiece of bee engineering and a crucial asset for the colony's future productivity.

In a tangential extractor, the weight of the honey on the inner side of the comb presses against the delicate wax foundation as the first side is extracted. Spinning too fast can "blow out" the comb, destroying this valuable asset.

Radial extractors exert a balanced, symmetrical force across the frame. This dramatically reduces the risk of comb damage, preserving the infrastructure your bees need to thrive. It’s a gentler, safer, and ultimately more professional approach.

Matching the Machine to the Mission

The choice between these two designs is not a matter of preference; it is a strategic decision about your operational model. You must match the tool to the scale of your ambition.

| Feature | Tangential Extractor | Radial Extractor |

|---|---|---|

| Core Mechanic | One side at a time; requires manual flipping | Both sides simultaneously; a "set it and forget it" process |

| Operational Model | Sequential Batch Processing | Continuous Parallel Processing |

| Labor Cost | High; creates a workflow bottleneck | Low; maximizes operator efficiency |

| Asset Risk | Higher risk of comb "blowouts" if not careful | Low risk; balanced forces protect the comb |

| Ideal Scale | Small hobbyist (1-4 hives) | Commercial operations & distributors (5+ hives) |

For commercial apiaries and beekeeping equipment distributors, the goal is always to maximize yield while minimizing operational drag. A tangential extractor, while functional, imposes a ceiling on your growth. A motorized, radial extractor is an investment in efficiency that pays for itself in saved labor and protected assets.

At HONESTBEE, we specialize in supplying durable, high-performance radial extractors designed for the demands of wholesale and commercial operations. We understand that your equipment is the engine of your profitability.

If you're ready to remove the bottleneck from your harvest and scale your operations, we can help you choose the right machine for your mission. Contact Our Experts

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

Related Articles

- How to Ethically Harvest Honey Without Compromising Bee Colony Survival

- How Honey Extractors Revolutionize Sustainable Beekeeping

- From Honey Hunter to Honey Manager: How to Double Yields Without Adding Hives

- How to Choose the Right Honey Extraction Method for Your Beekeeping Needs

- Centrifugal Extractors vs. Honey Presses: Choosing the Right Tool for Your Beekeeping Goals