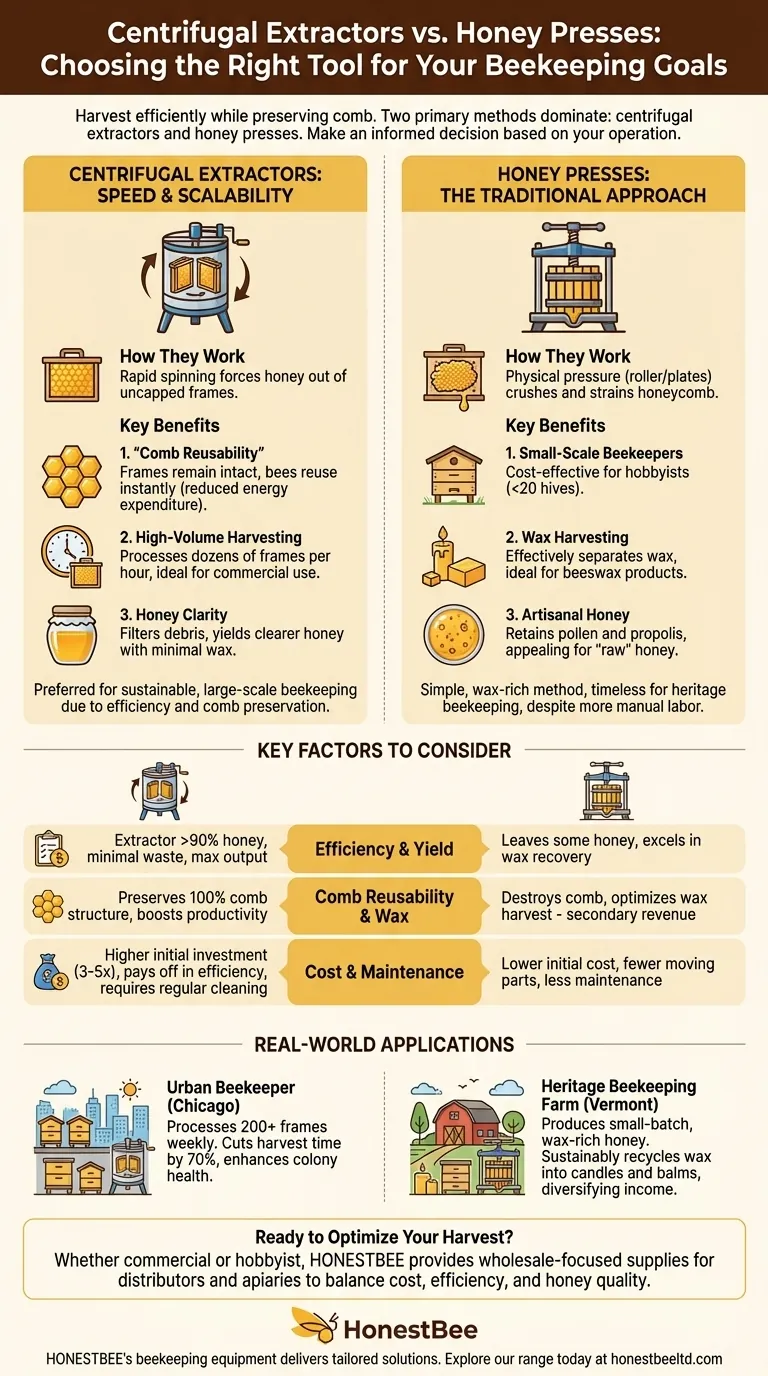

For beekeepers, harvesting honey efficiently while preserving comb integrity is a top priority. Two primary methods dominate the market: centrifugal extractors and honey presses. Each offers distinct advantages depending on your operation size, honey yield goals, and comb management preferences. This guide breaks down their functional differences, cost considerations, and real-world applications to help you make an informed decision.

Choosing the Right Honey Extraction Machine

How Centrifugal Extractors Work: Speed and Scalability

Centrifugal extractors use rapid spinning to force honey out of uncapped frames without damaging the comb. This method is ideal for beekeepers who prioritize:

- Comb Reusability: Frames remain intact, allowing bees to reuse them immediately—reducing the energy they expend rebuilding wax.

- High-Volume Harvesting: Extractors can process dozens of frames per hour, making them suitable for commercial operations.

- Honey Clarity: The centrifugal action filters out debris, yielding clearer honey with minimal wax residue.

Research shows that centrifugal models are the preferred choice for sustainable, large-scale beekeeping due to their efficiency and comb preservation.

The Traditional Approach: Mechanics of Honey Presses

Honey presses employ physical pressure (roller drums or plates) to crush and strain honeycomb. This method suits:

- Small-Scale Beekeepers: Presses are cost-effective for hobbyists or those with under 20 hives.

- Wax Harvesting: The crush-and-strain method separates wax more effectively, ideal for beekeepers selling beeswax products.

- Artisanal Honey: Pressed honey often retains more pollen and propolis, appealing to consumers seeking "raw" honey.

While presses require more manual labor, their simplicity and wax yield make them a timeless tool for heritage beekeeping.

Key Factors to Consider

Efficiency and Honey Yield Comparison

- Centrifugal Extractors: Extract over 90% of honey per frame, with minimal waste. Best for maximizing output in large apiaries.

- Honey Presses: May leave behind small amounts of honey in crushed comb but excel in wax recovery.

Impact on Honeycomb Reusability and Wax Preservation

- Extractors: Preserve 100% of comb structure; bees reuse frames instantly, boosting hive productivity.

- Presses: Destroy comb but optimize wax harvest—useful if wax is a secondary revenue stream.

Cost and Maintenance for Small vs. Large Operations

- Initial Investment: Centrifugal models cost significantly more (often 3–5x the price of presses) but pay off in long-term efficiency.

- Maintenance: Presses have fewer moving parts, reducing repair needs. Extractors require regular cleaning to prevent motor issues.

Real-World Applications

Case Study: Urban Beekeeper Using a Centrifugal Extractor

A rooftop apiary in Chicago processes 200+ frames weekly. Their radial extractor pays for itself in two seasons by:

- Cutting harvest time by 70% compared to manual pressing.

- Eliminating comb-rebuilding labor for bees, enhancing colony health.

Case Study: Heritage Beekeeping Farm with Honey Presses

A family-run farm in Vermont uses bucket presses to:

- Produce small-batch, wax-rich honey for local markets.

- Sustainably recycle wax into candles and balms, diversifying income.

Ready to Optimize Your Harvest?

Whether you’re a commercial grower prioritizing speed or a hobbyist valuing tradition, HONESTBEE’s beekeeping equipment delivers tailored solutions. Our wholesale-focused supplies help distributors and apiaries balance cost, efficiency, and honey quality—ensuring every harvest meets your goals.

Explore HONESTBEE’s range today and equip your operation with the right extraction tools.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

Related Articles

- How Honey Extractors Revolutionize Sustainable Beekeeping

- How to Ethically Harvest Honey Without Compromising Bee Colony Survival

- The Bottleneck in the Bee Yard: How Extractor Physics Dictates Apiary Scale

- How to Choose the Right Honey Extraction Method for Your Beekeeping Needs

- The Physics of Patience: Mastering Honey Extractor Speed to Save Your Combs