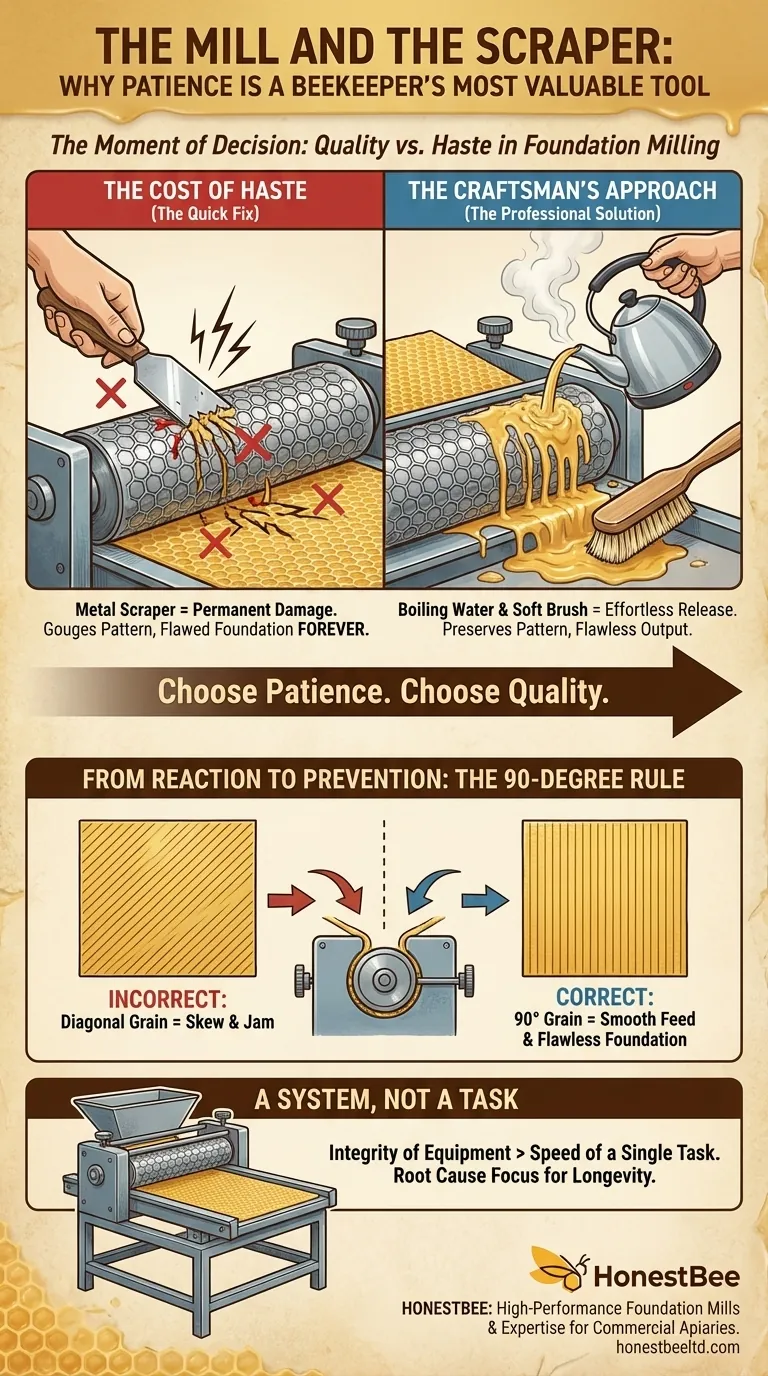

The Moment of Decision

Every beekeeper with a foundation mill knows the feeling. Production halts. A sheet has fed incorrectly, and now a thick, stubborn layer of wax clings to the intricate pattern of the rollers.

In that moment of frustration, the impulse is to fix it now. The nearest metal tool—a scraper, a screwdriver, a hive tool—looks like the perfect solution. It promises speed. It promises a quick return to work.

This is the most expensive mistake you can make. The real problem isn't the stuck wax; it's the choice you are about to make.

The Allure of the Quick Fix

Our minds are wired to solve immediate problems. The wax is there; the scraper will remove it. This is first-order thinking. It's effective for simple tasks, but disastrous when dealing with precision equipment.

The metal scraper feels satisfying. It offers tangible, immediate progress. But it ignores the second-order consequence: the unseen, permanent damage being inflicted on the heart of your operation.

This isn't a failure of skill, but of perspective. It's the triumph of impatience over investment.

The Scars of Haste

A foundation mill roller is a piece of precision engineering. Its surface is engraved with a perfect hexagonal pattern designed to be imprinted onto wax.

When a metal scraper gouges that surface, it doesn't just remove wax. It carves a permanent flaw into the steel. Every single foundation sheet that passes through those rollers from that moment on will carry an imprint of that mistake.

You aren't just cleaning wax. You are deciding the quality of every honeycomb you will produce for the life of the mill.

The Craftsman's Approach: Heat and Finesse

The professional solution is counter-intuitive. It requires less force, not more. It relies on principles of physics, not brute strength. It's a method of persuasion.

The goal is to convince the wax to let go, not to tear it away.

The Correct Procedure

- Apply Boiling Water: Heat is your primary tool. Pouring boiling water over the rollers instantly transfers thermal energy into the wax, melting it from a stubborn solid into a compliant liquid. Its bond with the metal breaks effortlessly.

- Use a Soft Brush: While the wax is liquid, a gentle brush with plastic or natural animal bristles is all that's needed. The bristles get into the fine grooves of the pattern, wiping the residue away without harming the underlying steel.

A hard rule for a long-lasting mill: Never let a metal tool touch the patterned roller surface.

Moving Upstream: From Reaction to Prevention

Stuck wax is rarely a random event. More often, it is a symptom of a flaw earlier in the process. Constantly cleaning your rollers is a sign that you are treating the symptom, not the cause.

The true cause often lies in the preparation of the raw wax sheets themselves.

The 90-Degree Rule

When a sheet of wax is dipped and cooled, it forms a "grain," much like wood. These are tiny, almost invisible ripples in the solidified wax.

- For flawless feeding: The grain must run at a perfect 90-degree angle to the sides of the sheet. This ensures it travels straight through the rollers.

- The primary cause of failure: If the grain runs diagonally, the sheet will inevitably skew, buckle, and jam as it enters the mill, causing the buildup you're trying to fix.

By mastering the dipping process, you don't just make better sheets. You make the problem of stuck wax almost disappear.

A System, Not a Task

Your foundation mill isn't just a machine; it's the heart of a system. Its health determines the quality of your output and the efficiency of your operation. The temptation to use a scraper is a decision to sacrifice the entire system for the sake of one frustrating moment.

Protecting that system requires discipline and a focus on root causes. It means valuing the integrity of your equipment over the speed of a single task. This philosophy is the foundation of any successful commercial apiary. High-quality, durable equipment is the starting point for producing flawless foundation sheets consistently.

At HONESTBEE, we supply commercial apiaries with the robust, high-performance foundation mills that a professional operation demands. We believe that the right equipment, combined with the right knowledge, is the key to longevity and success. Contact Our Experts

Visual Guide

Related Products

- Professional Honey Uncapping Roller for Efficient Harvesting

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Professional Multi-Function Stainless Steel Hive Tool

- Multi-Function Plier-Style Frame Grip Hive Tool

- Professional Honey Uncapping Fork Tool with Customizable Tine Options

Related Articles

- How to Uncap Honeycomb Safely: Professional Methods for Maximum Yield and Wax Preservation

- How to Master Essential Beekeeping Tools Safely and Efficiently

- How to Uncap Wax Like a Pro: Maximizing Honey Yield While Protecting Your Combs

- How Uncapping Forks Protect Honeycombs and Reduce Beekeeping Costs

- Precision Over Pace: The Strategic Role of the Uncapping Fork in Honey Harvesting