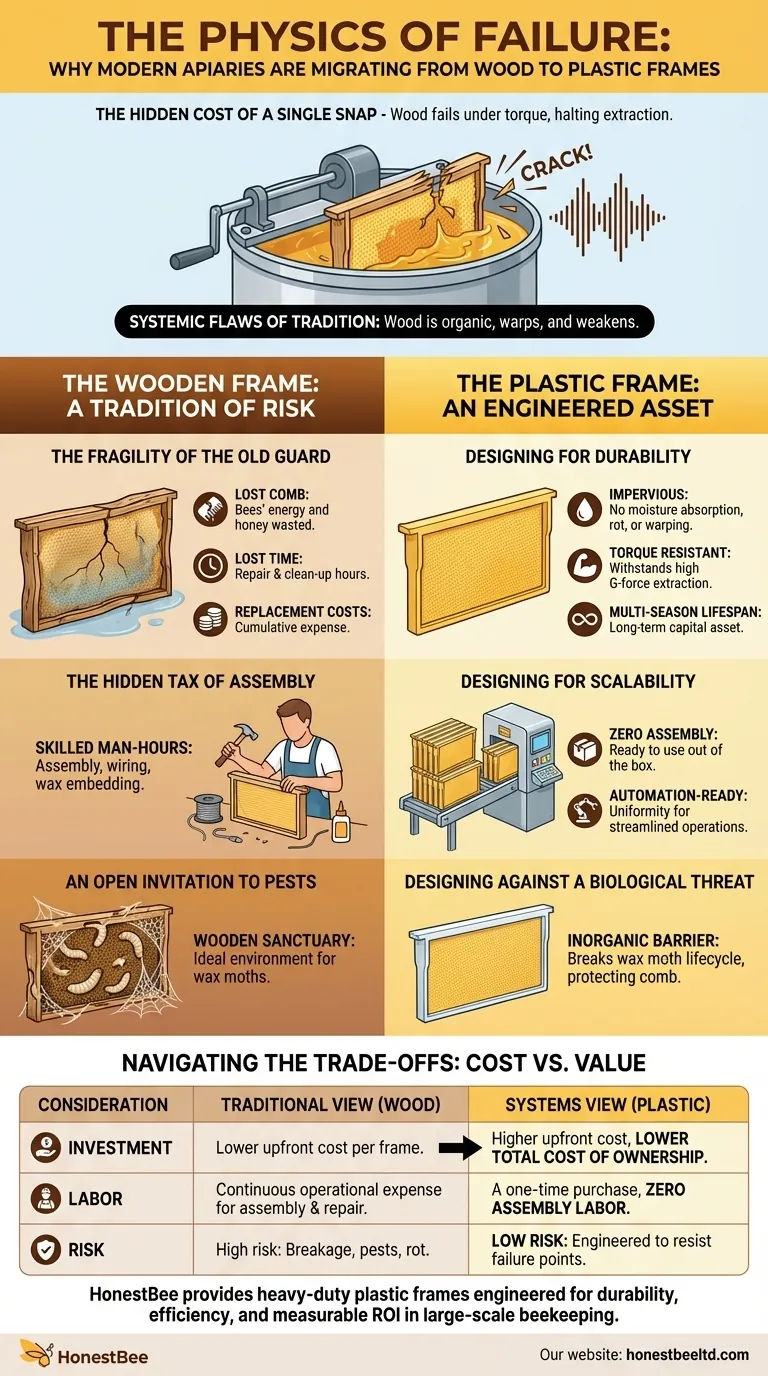

The Hidden Cost of a Single Snap

The honey house is a place of high-stakes choreography. It’s loud. The air is thick with the scent of beeswax and warm honey. An extractor spins at high G-force, a centrifuge designed to turn a season's work into liquid gold.

Then comes a sound that cuts through the hum: the sharp, splintering crack of wood.

The machine shudders to a stop. Inside, a wooden frame has failed under torque, exploding into pieces. The priceless drawn comb is destroyed, honey is slung unevenly, and the entire extraction process is halted. This single point of failure isn't just an inconvenience; it's a symptom of a systemic vulnerability built into the very architecture of a traditional hive.

The Systemic Flaws of Tradition

For centuries, wood was the only choice. It represents a rich history, but for a commercial apiary, relying on it introduces variables that silently erode efficiency and profit. The choice of frame material is not about tradition versus modernity; it’s a decision about risk management.

The Fragility of the Old Guard

Wood is an organic material. It absorbs moisture, it warps, and it weakens over time. Under the immense stress of a commercial extractor, or even just the repeated prying of a hive tool, it eventually gives out.

Every broken frame is a cascade of costs:

- Lost Comb: Bees expend enormous energy (and honey) to draw out a wax foundation. Destroyed comb is a massive setback in hive productivity.

- Lost Time: Every minute spent repairing frames or cleaning up a failed extraction is a minute not spent managing other hives.

- Replacement Costs: While a single wooden frame is inexpensive, the cumulative cost of constant replacement across hundreds or thousands of hives is a significant operational expense.

The Hidden Tax of Assembly

Before a wooden frame can even enter a hive, it demands labor. It must be assembled, squared, glued, and wired. Then, a sheet of wax foundation must be carefully embedded. This process, repeated thousands of times, represents a substantial investment in skilled man-hours—a hidden tax on every honey box you deploy.

An Open Invitation to Pests

Wax moths are a devastating parasite. Their larvae don't just eat wax; they tunnel through it, destroying the comb's integrity and leaving behind a mess of webbing. Wooden frames offer the perfect environment for them to thrive, burrowing into the soft wood to pupate and continue their destructive cycle. The frame itself becomes a Trojan horse for the hive’s biggest threat.

An Engineered Solution for a Biological System

The shift to plastic frames is not about abandoning nature. It’s about applying an engineering mindset to solve the inherent physical limitations of wood. A well-designed plastic frame is a tool for optimizing a biological manufacturing process.

Designing for Durability

A single-piece, molded plastic frame is fundamentally stronger. It is an integrated system of foundation and structure, designed to be rigid and uniform.

- It is impervious to moisture and will not warp or rot.

- It withstands the immense torque of extraction without flinching.

- Its lifespan is measured in many seasons, not just one or two.

This isn't just about avoiding breakage; it's about predictable, repeatable performance. It transforms the frame from a consumable good into a long-term capital asset.

Designing for Scalability

For commercial operations, efficiency is scalability. Plastic frames, often pre-coated with beeswax, are ready to use out of the box.

- Zero Assembly: The labor-intensive process of building frames is completely eliminated. This frees up countless hours, allowing operators to manage more hives more effectively.

- Automation-Ready: Their perfect uniformity makes them ideal for automated uncapping lines, further streamlining honey house operations.

This reduction in labor creates leverage. It allows an apiary to grow without a linear increase in its workforce.

Designing Against a Biological Threat

Plastic is inorganic. A wax moth larva cannot tunnel into it. By using plastic frames, you break the pest's lifecycle. It removes the wooden sanctuary where they pupate, protecting your most valuable in-hive asset: the drawn comb. It’s a simple material change that acts as a powerful, built-in pest management system.

Navigating the Trade-offs: Cost vs. Value

No solution is without its considerations. The arguments for wood often center on initial cost and bee acceptance, but a deeper look reveals a different story.

| Consideration | The Traditional View (Wood) | The Systems View (Plastic) |

|---|---|---|

| Investment | Lower upfront cost per frame. | Higher upfront cost, but a far lower total cost of ownership. |

| Labor | A continuous operational expense for assembly & repair. | A one-time purchase that eliminates assembly labor costs. |

| Risk | High risk of loss from breakage, pests, and rot. | Low risk; engineered to resist the most common points of failure. |

| Bee Acceptance | Bees readily accept natural wax on wood. | May require a thin extra wax coat, a minor task for major gains. |

The choice becomes clear when you stop thinking about the cost of a frame and start thinking about the value of your time, the security of your comb, and the long-term resilience of your operation.

As a leading wholesale supplier to commercial apiaries, HONESTBEE is focused on providing equipment that delivers a measurable return on investment. Our heavy-duty plastic frames are engineered for the realities of large-scale beekeeping, where durability and efficiency are not just conveniences—they are the foundation of a profitable business.

If you are ready to move beyond treating symptoms and start optimizing your entire system, we can help. Contact Our Experts

Visual Guide

Related Products

- Wooden Bee Hive Frames for Beekeeping and Wholesale

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Copper Bee Frame Eyelets for Beekeeping

- Heavy-Duty Nylon Beehive Hive Strap with Stainless Steel Cinch Buckle

- HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

Related Articles

- Tired of Sagging Comb? The Hidden Cost of "Cheap" Beekeeping Frames

- How to Wire Beehive Frames for Maximum Durability and Honey Production

- How to Choose Beehive Frames: Balancing Bee Health, Honey Yield, and Beekeeper Convenience

- Beyond Extraction: Why Foundationless Frames Are the Key to High-Value Comb Honey

- The Architecture of Instinct: Why Three Numbers Define a Beehive's Success