It's a familiar scene for many honey producers: the end of a long bottling run. A sticky film seems to cover every surface. A crate of finished jars shows frustratingly inconsistent fill levels—some just a little too low, others slightly overfilled. And despite your best efforts, drips and strings have marred the otherwise beautiful packaging. It feels less like a professional process and more like a constant battle against the product itself.

If this sounds like your operation, you are not alone. And the root of the problem is more complex than just "honey is thick."

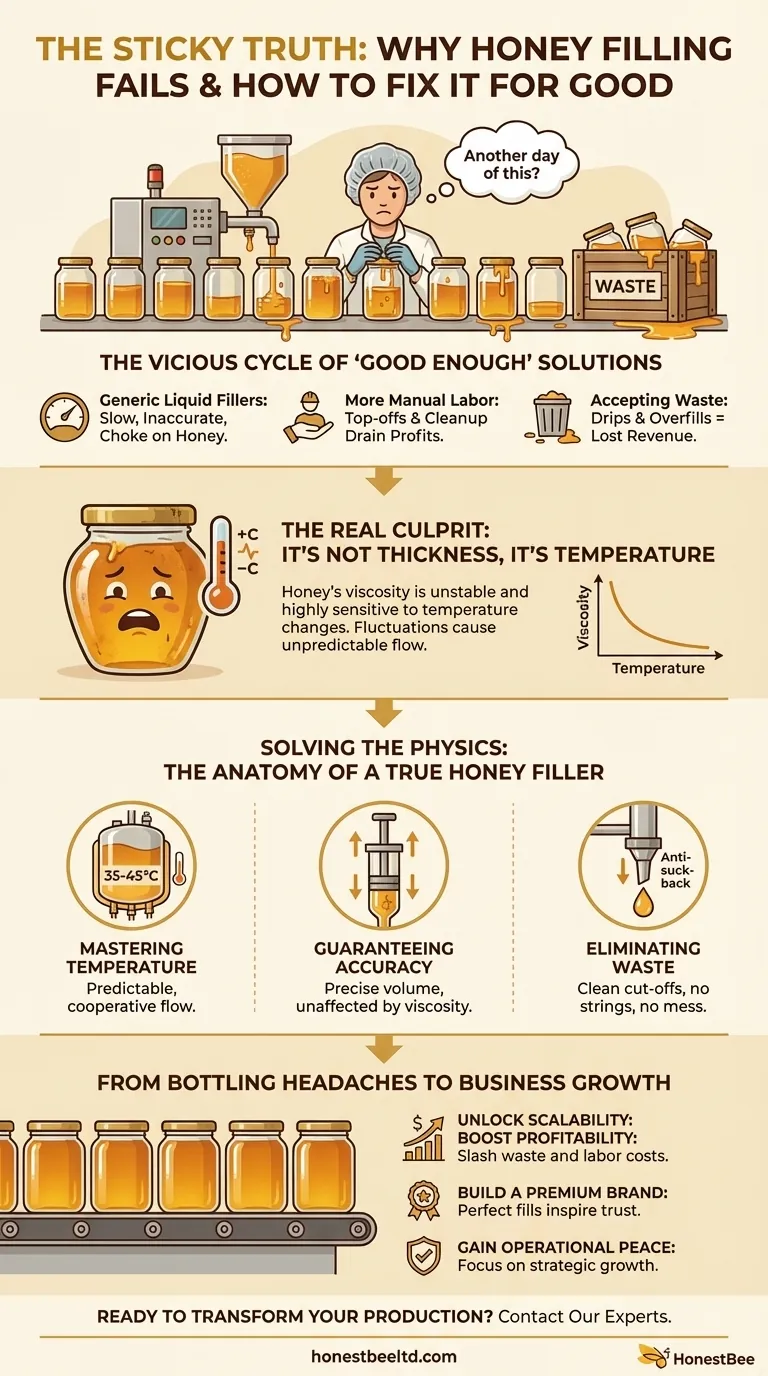

The Vicious Cycle of 'Good Enough' Solutions

When faced with bottling challenges, most businesses try to muscle their way through the problem. The common "solutions" are often just workarounds that create new problems:

- Using generic liquid fillers: Standard gravity fillers, designed for free-flowing liquids like water, choke on honey. This leads to painfully slow production rates and wildly inaccurate fills.

- Assigning more manual labor: Relying on staff to manually top-off jars or spend hours on cleanup is a direct drain on your profits. It's a process that can't scale as your business grows.

- Accepting the waste: Small drips and overfills on every jar add up. Over a year, this "cost of doing business" can represent a significant amount of lost product and revenue.

These struggles aren't just operational headaches; they are business liabilities. They cap your production capacity, increase your cost-per-jar, and risk damaging your brand's reputation with every inconsistently filled product that reaches a store shelf.

The Real Culprit: It's Not Thickness, It's Temperature

Here is the turning point: the fundamental mistake is treating honey's viscosity as a constant. It's not. The real enemy of a consistent bottling line isn't honey's thickness; it's honey's instability.

Honey's viscosity—its resistance to flow—is extremely sensitive to temperature. A drop of just a few degrees can cause it to thicken dramatically, while a slight increase makes it flow much more easily.

This is the hidden variable that wreaks havoc on your consistency. A machine that fills perfectly in a warm afternoon might under-fill bottles on a cool morning. Why do the "common solutions" fail? Because they are fighting the symptom (thickness) while completely ignoring the root cause (uncontrolled temperature). You can't achieve a predictable output when a core physical property of your product is fluctuating all day long.

Solving the Physics: The Anatomy of a True Honey Filler

To tame this instability, you don't need a stronger machine; you need a smarter one. You need an integrated system designed from the ground up to control the physics of honey. This is where professional-grade equipment moves beyond simple pumping and becomes a precision instrument.

1. Mastering Temperature for Predictable Flow

The first step is to stop fighting viscosity and start managing it. A purpose-built honey filler does this with a heated, jacketed tank and heated nozzles. This system maintains the honey at a precise, consistent temperature (typically 35-45°C), transforming it from a stubborn, unpredictable mass into a predictable, cooperative liquid that flows smoothly every time.

2. Guaranteeing Accuracy with the Right Pump

With flow stabilized, the next challenge is ensuring every jar gets the exact same amount. This is the job of a Piston Filler. As a positive displacement pump, it measures by volume, not flow. It isolates a precise amount of honey in a cylinder and dispenses it. This mechanism is unaffected by minor viscosity changes, delivering machine-like accuracy, jar after jar.

3. Eliminating Waste with Clean Cut-offs

Finally, to solve the mess and waste, the system needs a clean ending. Specialized anti-drip nozzles are designed for this. They use features like a "suck-back" or a positive shut-off valve to instantly and cleanly cut the honey stream, preventing the strings and drips that waste product and require extensive cleanup.

This combination of temperature control, volumetric filling, and anti-drip technology isn't a collection of features; it's a complete solution engineered to address the fundamental scientific challenges of honey.

From Bottling Headaches to Business Growth

When you stop fighting a losing battle with your honey and instead use a system designed to control it, everything changes. The benefits extend far beyond a cleaner workspace.

- You unlock scalability: You can now confidently take on larger orders from distributors, knowing your process can handle the volume efficiently and consistently.

- You boost profitability: With waste eliminated, labor costs for cleanup slashed, and throughput dramatically increased, your cost-per-jar plummets.

- You build a premium brand: Every jar that leaves your facility is a perfect representation of your quality, with clean packaging and a precise fill line that inspires consumer trust.

- You gain operational peace of mind: Your focus can shift from overseeing a frustrating, manual process to strategic activities—like finding new customers and growing your business.

This isn't just about investing in a better machine; it's about adopting a professional process that allows your business to reach its full potential. By understanding and solving the root cause of your bottling issues, you transform a major operational bottleneck into a competitive advantage. If your ambition is to grow from a local supplier to a regional powerhouse, mastering your packaging process is non-negotiable.

Ready to see how a system engineered for honey's unique properties can transform your production line? Our team specializes in equipping commercial apiaries and distributors with solutions that deliver accuracy, efficiency, and growth. Let's discuss the specific challenges of your operation and design a system that works for you. Contact Our Experts.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

Related Articles

- How Honey Bottle Designs Combine Convenience, Safety, and Sustainability

- The Unseen Cost of Manual Honey Filling: A Case for Automation

- Containing Liquid Gold: The Silent Engineering Inside Every Honey Jar

- How Bee Behavior and Weather Dictate Optimal Honey Harvest Times

- How to Choose Honey Containers That Ensure Safety, Compliance, and Quality