The Bottleneck in the Sweetest Business

Picture a commercial apiary during peak honey flow. The hives operate with a quiet, relentless efficiency—a perfect system of production. Then, the process moves indoors to the packaging room.

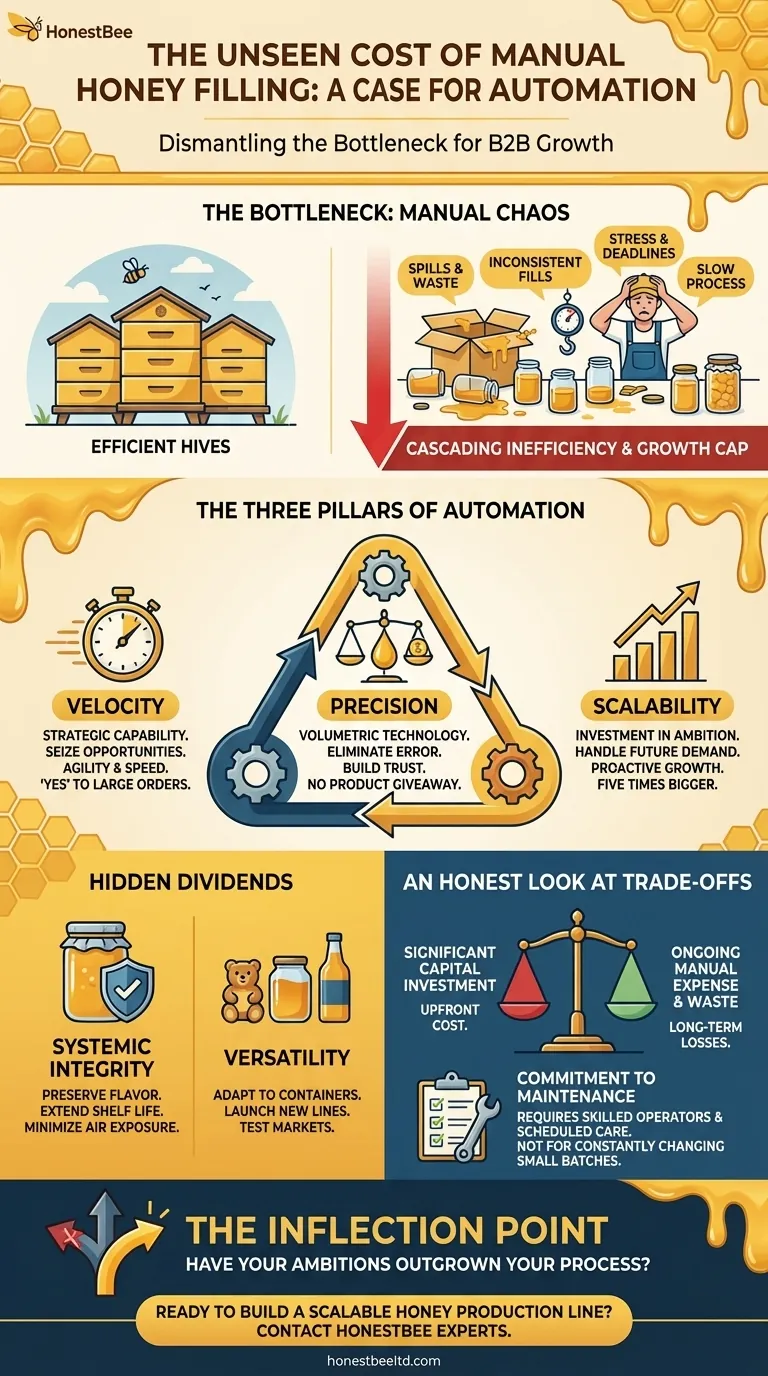

If it’s a manual operation, the scene shifts. The air is thick with the stress of meeting deadlines. Spills create sticky, slow-moving chaos. Every jar is filled by eye or by a simple scale, leading to tiny, costly variations.

This is the bottleneck. It's not just about being slow. It’s a source of cascading inefficiency, product waste, and a psychological cap on your business's growth. The decision to automate is about dismantling this bottleneck, piece by piece.

The Three Pillars of Production Freedom

Moving to an automatic filling machine is a fundamental shift in operational philosophy. It rests on three transformative advantages that address the core limitations of manual labor.

Velocity: Escaping the Tyranny of the Clock

The most obvious benefit of an automated filler is speed. But thinking of it in "jars per hour" misses the point.

True velocity is a strategic capability. It's the power to say "yes" to a sudden large order from a new distributor. It's the ability to clear a massive harvest in days, not weeks, preserving freshness and freeing up capital. A machine that fills thousands of containers an hour doesn't just make you faster; it makes your business more agile and opportunistic.

Precision: The Quiet Confidence of Consistency

Inconsistency is a hidden tax on your profits. An overfilled jar is free product given away. An underfilled jar can damage your brand's reputation with a customer who feels shorted. Manual filling, no matter how skilled the operator, invites human error into every single package.

Automatic fillers, often using volumetric technology, eliminate this variable. They dispense the exact same amount of honey, every single time. This isn't just about quality control; it's about building a foundation of trust. Every customer gets exactly what they paid for, and you stop losing money one gram at a time.

Scalability: Designing for a Future You Haven't Met Yet

The most significant psychological barrier to growth is often the fear that your operations can't handle success. You hesitate to pursue larger contracts because you know the chaos it would create in your packaging room.

An automatic filling machine is an investment in ambition. It provides the capacity to handle a future that is five times bigger than your present, without a proportional increase in labor or a decrease in quality. It allows you to think proactively about growth instead of reacting to the constraints of your current setup.

The Hidden Dividends of Automation

Beyond the core pillars, automation pays dividends in areas that are harder to quantify but just as critical.

Systemic Integrity and Versatility

Modern fillers do more than just dispense honey. They are engineered to protect it, often minimizing its exposure to air, which helps preserve its delicate flavor profile and extend shelf life.

Furthermore, these machines are not one-trick ponies. The best systems can be quickly configured for different container sizes and shapes—from small bear-shaped bottles to large glass jars. This built-in versatility means you can launch new product lines or test market different packaging without investing in entirely new equipment.

The Professional's Toolkit

Here’s a clear breakdown of the core benefits:

| Key Advantage | The Deeper Impact on Your Operation |

|---|---|

| Speed & Efficiency | Seize larger market opportunities and reduce per-unit labor costs. |

| Consistency & Precision | Eliminate product waste from overfills and build unwavering brand trust. |

| Scalability for Growth | Remove the operational fear of success; grow without constraint. |

| Enhanced Versatility | Adapt to new products and packaging, future-proofing your investment. |

An Honest Look at the Trade-Offs

No technology is a universal solution. Acknowledging the trade-offs is crucial for making the right strategic decision.

The Upfront Calculus: Investment vs. Expense

An automatic filling machine is a significant capital investment. This is the primary consideration. However, it’s critical to weigh this one-time cost against the slow, ongoing expenses of manual labor, product waste, and—most importantly—missed opportunities.

The Commitment to Maintenance

This is sophisticated equipment. It requires a commitment to a preventative maintenance schedule and operators who understand the machinery. A breakdown can halt production, so treating the machine as a core asset, not just a tool, is essential for long-term success.

For operations built around very small, highly customized, and constantly changing batches, the setup time might outweigh the speed advantage. In these niche cases, semi-automatic solutions can offer a more flexible middle ground.

The Inflection Point for Growth

The decision to automate is an answer to a simple question: Have your ambitions outgrown your current process?

For the commercial apiaries and distributors that HONESTBEE serves, this inflection point is a familiar milestone. It's the moment when the cost of not automating—in lost efficiency, wasted product, and held-back growth—becomes greater than the cost of the machine itself. Investing in the right filling technology isn't just an upgrade; it's the foundation for the next stage of your business.

Ready to build a more efficient, reliable, and scalable honey production line? Contact Our Experts

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Manual Honey Filling Machine Bottling Machine for Honey

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

Related Articles

- How to Choose a Honey Filling Machine: Balancing Efficiency, Customization, and Cost

- The 40°C Rule: How Gentle Heat Protects the Soul of Your Honey

- Unlock Self-Sufficiency: The HONESTBEE Semi-Automatic Bee Frame Machine – Your All-in-One Workshop Solution

- How to Make Bee Frames in a Factory: The Ultimate Guide to High-Volume Production with HONESTBEE Bee Frame Machines

- How Automated Frame-Making Revolutionizes Beehive Production Efficiency