For dedicated beekeepers and small-scale beekeeping equipment workshops, the quest for quality, control, and cost-effectiveness in producing bee frames is ongoing. Purchasing pre-made frames can be expensive, and relying on multiple, separate machines for each component can be space-consuming and inefficient. HONESTBEE introduces a groundbreaking solution: the Semi-Automatic Bee Frame Making Machine, a versatile and compact powerhouse designed to empower you to produce complete hive frames – top bars, bottom bars, and side bars – all from a single, ingeniously designed unit.

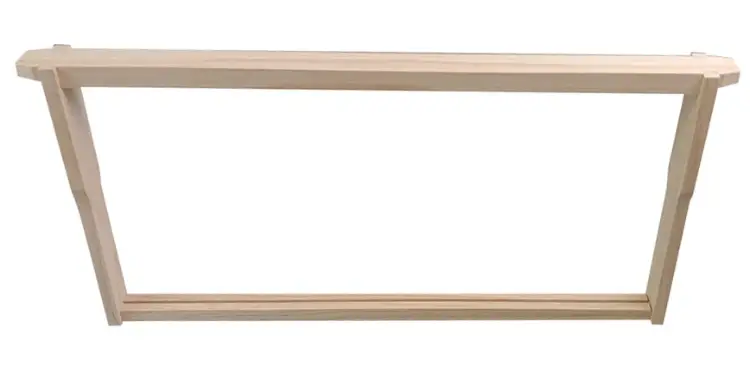

This isn't just a tool; it's your complete in-house frame factory, perfect for Langstroth, Dadant, and other frame styles, putting you in full control of your beekeeping equipment production.

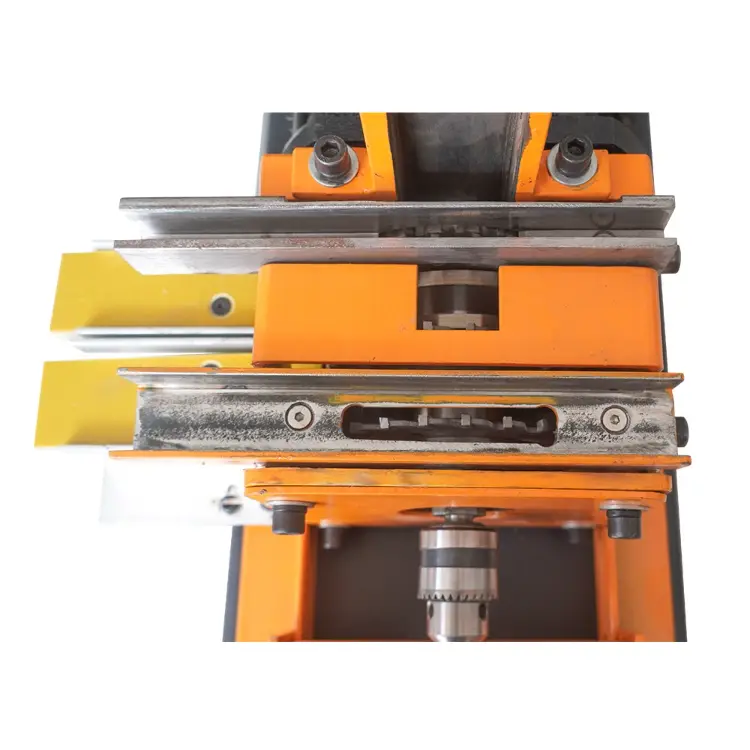

Meet the All-in-One Solution: One Machine, Every Frame Part

Unlike specialized single-task machines, this unit integrates multiple functions, allowing a single operator to process raw timber into finished frame components with precision and ease. Its compact, benchtop design, featuring a robust electric motor and clearly defined processing stations, makes it an ideal fit for workshops where space and efficiency are key.

Let's break down the incredible versatility demonstrated:

- Side Bar Drilling Holes:

- Function: Precisely drills multiple holes along the length of the side bars. An adjustable ruler/guide ensures accurate and repeatable hole spacing.

- Purpose: Essential for inserting bee frame eyelets, which are then used for wiring the frame to support beeswax foundation. This step is crucial for creating strong, well-supported combs.

- Side Bar Double End Grooving:

- Function: Mills a groove into both ends of the side bars.

- Purpose: This creates a secure interlocking joint when the side bars meet the top and bottom bars, significantly enhancing the frame's structural integrity and squareness. (Often used in Hoffman-style or similar self-spacing frames).

- Side Bar Double End Edge Milling:

- Function: Shapes the edges of the side bar ends, often creating the characteristic "shoulders" of Hoffman self-spacing frames.

- Purpose: Hoffman frames are designed to provide correct bee space between frames automatically, simplifying hive management. This milling creates that vital self-spacing feature.

- Bottom Bar Double End Straight Tenon Forming:

- Function: Cuts a straight tenon (a projecting piece of wood) on both ends of the bottom bar.

- Purpose: These tenons fit snugly into the grooves or mortises of the side bars, forming a strong and stable base for the frame.

- Bottom Bar Grooving:

- Function: Mills a central groove along the length of the bottom bar.

- Purpose: This groove is designed to securely hold the bottom edge of the beeswax foundation sheet, preventing it from bowing or detaching.

- Top Bar Double End Grooving:

- Function: Mills a groove into both ends of the top bar.

- Purpose: Similar to side bar end grooving, this prepares the top bar to interlock securely with the side bars, contributing to a robust frame structure.

- Top Bar Grooving (for embedding bee foundation):

- Function: Creates a groove along the underside of the top bar.

- Purpose: This is the primary groove for inserting and securing the beeswax foundation sheet within the frame. Some beekeepers also use this groove with a wedge strip for extra foundation security.

- Top Bar Double End L-Tenon Forming:

- Function: Creates an "L" shaped tenon on both ends of the top bar. This is a common feature for many frame designs, including Langstroth.

- Purpose: These L-tenons rest on the frame rests within the hive body, allowing the frame to be easily hung and removed while maintaining correct spacing.

Why the HONESTBEE Semi-Automatic Bee Frame Machine is Your Workshop's Best Friend

This multi-functional bee frame machine offers a compelling array of benefits, especially for individual beekeepers and smaller-scale commercial operations:

- Unmatched All-in-One Convenience:

- The Advantage: Eliminates the need for multiple separate machines (drill press, router table, tenoning jig, specific grooving machines).

- Your Gain: Saves significant workshop space, reduces setup time between different operations, and simplifies the overall workflow. One machine handles it all!

- Significant Cost-Effectiveness:

- The Advantage: A lower initial investment compared to purchasing several specialized machines. Allows you to utilize your own timber.

- Your Gain: Drastically reduces the cost per frame compared to buying pre-manufactured frames. Offers a faster return on investment and greater control over material costs.

- Precision and Consistency for Superior Frames:

- The Advantage: Machined components ensure uniformity in dimensions, hole placement, and joint quality.

- Your Gain: Produce frames that are consistently square, strong, and perfectly dimensioned. This leads to easier hive management, better comb construction by bees, and longer-lasting equipment.

- Tailored to Your Beekeeping Style – Langstroth, Dadant & More:

- The Advantage: While ideal for Langstroth and Dadant frame production due to its versatile grooving and tenoning capabilities, the adjustable guides and tooling options can often be adapted for other frame styles or custom requirements.

- Your Gain: Flexibility to produce the specific frame types you and your customers need without being locked into a single pre-made standard.

- Empowerment and Control Over Your Supply:

- The Advantage: Produce frames on demand, to your exact quality standards.

- Your Gain: No more waiting for suppliers or being subject to price fluctuations of pre-made frames. Gain self-sufficiency and the ability to respond quickly to your needs or customer orders.

- Global Electrical Compatibility:

- The Advantage: Standard single-phase 220V operation, with the crucial ability for HONESTBEE to customize the machine for single-phase 110V or other specific local voltage requirements.

- Your Gain: Use the machine anywhere in the world without the need for cumbersome voltage converters.

Mastering Your Frame Production: Operation & Best Practices

This HONESTBEE bee frame machine is designed for user-friendliness, but understanding its operation ensures optimal results and safety:

- Preparation is Key:

- Start with good quality, appropriately dried timber, pre-cut to the basic lengths for your top bars, bottom bars, and side bars.

- Ensure the correct drill bit or cutting tool is securely installed in the machine's chuck/spindle for the desired operation.

- Adjust the integrated rulers and guides precisely for the specific dimensions of the component and the operation you are performing.

- Operational Workflow (One Function at a Time):

- Select Function: Mentally (or by adjusting tooling if necessary) choose the operation you want to perform (e.g., side bar drilling).

- Adjust Guides: Set the fences and depth stops according to your frame part specifications.

- Power On: Switch on the main motor.

- Process Timber: Carefully feed the wooden component into the machine against the guides, allowing the drill or cutter to perform its function. For operations like end tenoning or grooving, you will typically push the wood piece towards the cutter. For drilling, you align the wood and advance it onto the drill bit.

- Repeat for all identical parts requiring that specific operation.

- Switch Function: If moving to a different operation (e.g., from drilling side bars to grooving top bars), power off the machine, change tooling if necessary, and readjust guides.

- Safety First – Your Priority:

- Always wear appropriate Personal Protective Equipment (PPE): Safety glasses are essential. Dust masks and hearing protection are also highly recommended.

- Keep Hands Clear: Be constantly aware of the rotating cutter/drill bit. Use push sticks or hold-downs where appropriate, especially for smaller pieces.

- Secure Workpiece: Ensure the wood is held firmly against the guides during operation.

- One Operator: This machine is designed for single-person operation.

- Understand Your Machine: Before first use, thoroughly familiarize yourself with all controls, adjustment points, and potential hazards.

- Maintenance for Longevity:

- Keep the machine clean from sawdust buildup, which can affect accuracy and become a fire hazard.

- Regularly check that drill bits and cutting tools are sharp. Dull tools lead to poor cuts and strain the motor.

- Inspect moving parts and ensure all bolts and fixtures are secure.

The HONESTBEE Advantage vs. Alternative Methods

- Buying Pre-Made Frames:

- Pros: Convenient.

- Cons: Significantly more expensive per frame, no control over wood quality or construction precision, subject to supplier availability.

- Manual Methods (Hand tools, basic drill press, router):

- Pros: Low initial tool cost.

- Cons: Extremely time-consuming, highly labor-intensive, difficult to achieve consistent precision, physically demanding, not practical for more than a few frames.

- Using Multiple Separate Benchtop Machines:

- Pros: Can achieve good results.

- Cons: Higher overall investment, requires much more workshop space, significant time spent moving between machines and setting up for each different operation.

- The HONESTBEE Semi-Automatic Bee Frame Machine:

- Pros: The optimal balance of affordability, versatility, space-saving design, and precision for beekeepers and small workshops. One machine performs multiple critical operations, offering a clear path to self-sufficient, high-quality frame production.

Is This Your Path to Frame Self-Sufficiency and Enhanced Quality?

If you are a beekeeper managing a growing number of hives, or a small business supplying local beekeepers, and you're looking for:

- A way to significantly reduce the cost of your bee frames?

- Greater control over the quality and design of your frames?

- The ability to produce frames for Langstroth, Dadant, or even custom hives?

- A space-saving, versatile bee frame machine solution?

- A method to turn timber into a valuable asset efficiently?

Then the HONESTBEE Semi-Automatic Bee Frame Making Machine is the strategic investment your workshop needs.

Take Control of Your Bee Frame Production with HONESTBEE's Versatile Machine!

Stop compromising on frame quality or paying premium prices for pre-made equipment. The HONESTBEE Semi-Automatic Bee Frame Machine empowers you to produce professional-grade bee frames for Langstroth, Dadant, and other hive types, all within your own workshop. Increase your efficiency, ensure precision, and gain true self-sufficiency.

Contact HONESTBEE today to learn more about this all-in-one bee frame making solution. Let's discuss your specific needs, voltage requirements, and how this incredible machine can become the cornerstone of your beekeeping equipment production!

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

Related Articles

- How to Make Bee Frames in a Factory: The Ultimate Guide to High-Volume Production with HONESTBEE Bee Frame Machines

- Mastering Bee Frame Production: A Factory-Scale Guide with Advanced Bee Frame Machine Solutions

- Scaling Up Your Beekeeping Operation: How an HonestBee Bee Frame Machine Fuels Growth

- How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges

- Revolutionize Your Workshop: The Ultimate Bee Frame Side Bar Forming Machine for Unmatched Efficiency & Customization