The Beekeeper's Dilemma: A Race Against the Calendar

For a honeybee colony, fall is not a season of gentle decline. It is a frantic, metabolic race against the dropping sun and the coming cold. Every calorie counts. The colony’s survival through winter hinges on its ability to gather and store enough energy to sustain its cluster for months of confinement.

The modern beekeeper’s role in this period shifts from passive manager to active survival engineer. The central challenge is clear: how do you deliver a massive caloric surplus to the colony, efficiently and safely, without triggering chaos like robbing or introducing new environmental dangers?

This isn't just about providing food. It's a logistical problem of scale, timing, and risk management.

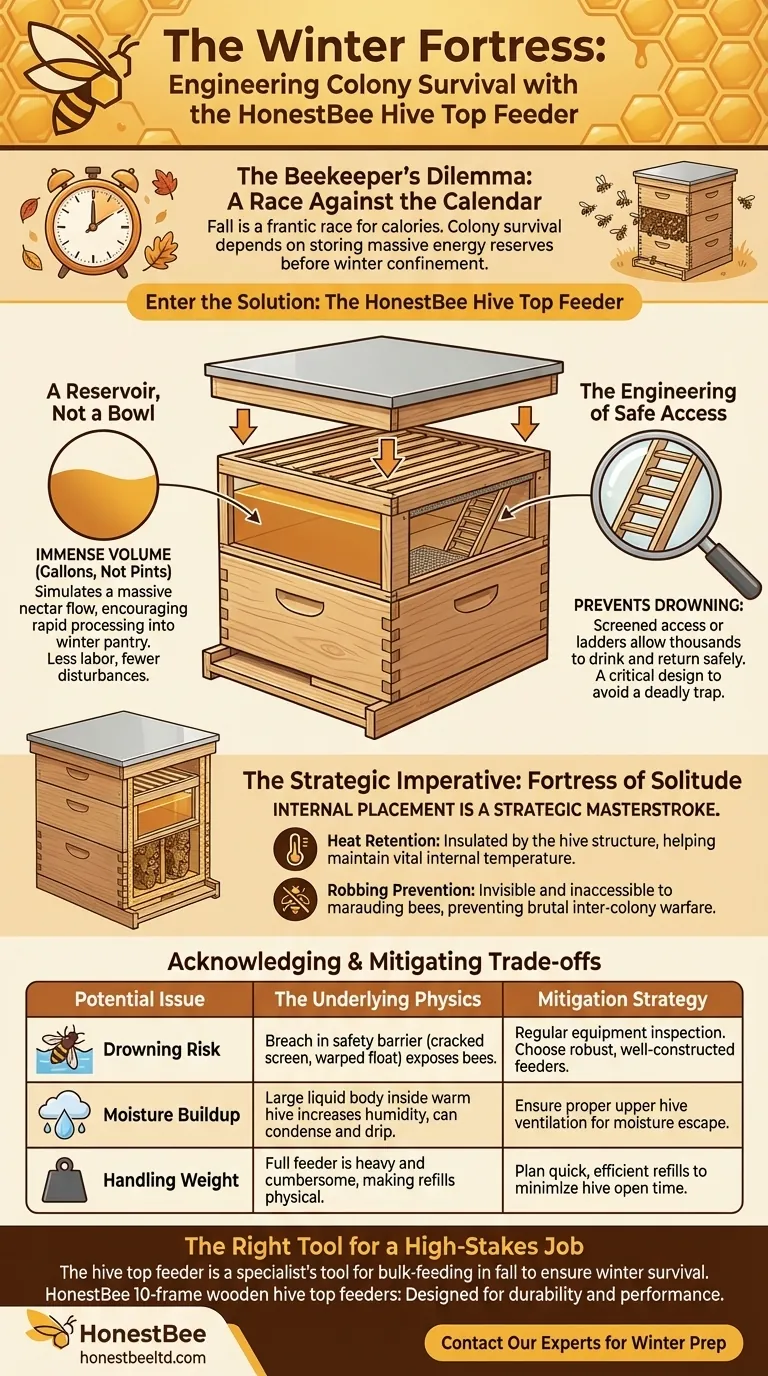

Anatomy of a Solution: The Hive Top Feeder

Enter the 10-frame wooden hive top feeder. It appears simple—a wooden box that sits atop the hive—but its design represents an elegant solution to a complex set of problems. It’s not just a feeding tray; it's a self-contained logistical system.

A Reservoir, Not a Bowl

The feeder's primary advantage is its immense volume. It can hold gallons of sugar syrup, not pints. This capacity changes the psychological dynamic for both the bees and the beekeeper.

For the beekeeper, it means fewer visits, which translates to less disturbance and lower labor costs—a critical factor in commercial operations.

For the bees, it simulates a massive, late-season nectar flow. This encourages them to take down the syrup with urgency and process it into stored "honey," rapidly building the winter pantry they instinctually know they need.

The Engineering of Safe Access

The most critical design element is also the most subtle: the mechanism that prevents bees from drowning. A feeder that kills the bees it's meant to save is a failed design.

Most hive top feeders use screened central access, wooden floats, or integrated "ladders." This allows thousands of bees to safely access the syrup's surface, drink, and return to the hive. It’s a beautifully simple solution to a fluid dynamics problem, ensuring the life-saving resource doesn’t become a deadly trap.

The Strategic Imperative: Fortress of Solitude

While many feeders exist, the hive top feeder is the tool of choice for the specific, high-stakes mission of winter preparation. Its placement inside the hive stack is a strategic masterstroke.

The Fall Calorie Rush

In autumn, beekeepers provide a heavy 2:1 sugar-to-water syrup. This thick mixture is less for immediate consumption and more for efficient storage. The hive top feeder's large reservoir is ideal for this task, allowing the colony to move gallons of it in a matter of days. The same space can also hold solid winter patties, providing versatility as temperatures drop.

A Defense Against Chaos

Placing the feeder inside the hive, directly under the main cover, creates a fortress.

- Heat Retention: The feeder is insulated by the hive structure itself, helping the colony maintain its vital internal temperature. An external feeder would force bees to break cluster and face the cold.

- Robbing Prevention: Robbing is a brutal form of warfare between colonies. An open or external food source can incite a frenzy that destroys a weaker hive. By being internal, the hive top feeder is virtually invisible and inaccessible to marauding bees from other hives.

Acknowledging the Trade-offs

No engineering solution is without its trade-offs. An effective manager understands the limitations and failure points of their tools.

| Potential Issue | The Underlying Physics | Mitigation Strategy |

|---|---|---|

| Drowning Risk | A breach in the safety barrier (e.g., a cracked screen or warped float) exposes bees to the main liquid reservoir. | Regular equipment inspection. Choose well-constructed feeders with robust and properly fitted ladders. |

| Moisture Buildup | A large body of liquid inside a warm hive will increase humidity. In cold weather, this can condense and drip. | Ensure proper upper hive ventilation to allow excess moist air to escape. |

| Handling Weight | A feeder full of syrup is heavy and cumbersome, making refills a physical task. | Plan refills to be quick and efficient to minimize the time the hive is open. |

The Right Tool for a High-Stakes Job

Your choice of feeder is a declaration of your objective. While a small entrance feeder might be perfect for stimulating a small colony in the spring, it is completely inadequate for the bulk-feeding required in the fall.

The hive top feeder is a specialist's tool. It is the choice you make when your goal is to efficiently and safely load a colony with the maximum amount of resources needed to survive the single greatest threat it faces: winter. For commercial apiaries, where efficiency and colony survival are directly tied to profitability, this isn't a luxury; it's a cornerstone of sound management.

At HONESTBEE, we build equipment for professionals who understand these stakes. Our 10-frame wooden hive top feeders are designed for durability and performance, ensuring you can execute your winter feeding strategy with confidence. To ensure your colonies are prepared for the coming season, Contact Our Experts

Visual Guide

Related Products

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- HONESTBEE Square Top Hive Bee Feeder Top Bee Feeder

- Professional Hive Top Bee Feeder for Beekeeping

- HONESTBEE Round Hive Top Bee Feeder for Syrup

- Professional In-Hive Bee Feeder HONESTBEE Frame for Beekeeping

Related Articles

- The Slippery Wall Problem: A Fatal Design Flaw in Bee Feeders

- The Paradox of Plenty: Why Warm Winters Are a Silent Threat to Bee Colonies

- How to Choose the Right Bee Feeder: Matching Capacity and Feeding Rates to Your Hive

- Optimizing Winter Beehive Survival: A Guide to Top Feeders for Cold-Weather Beekeeping

- How Pro Feeders Enhance Hive Health in Langstroth Beekeeping Systems