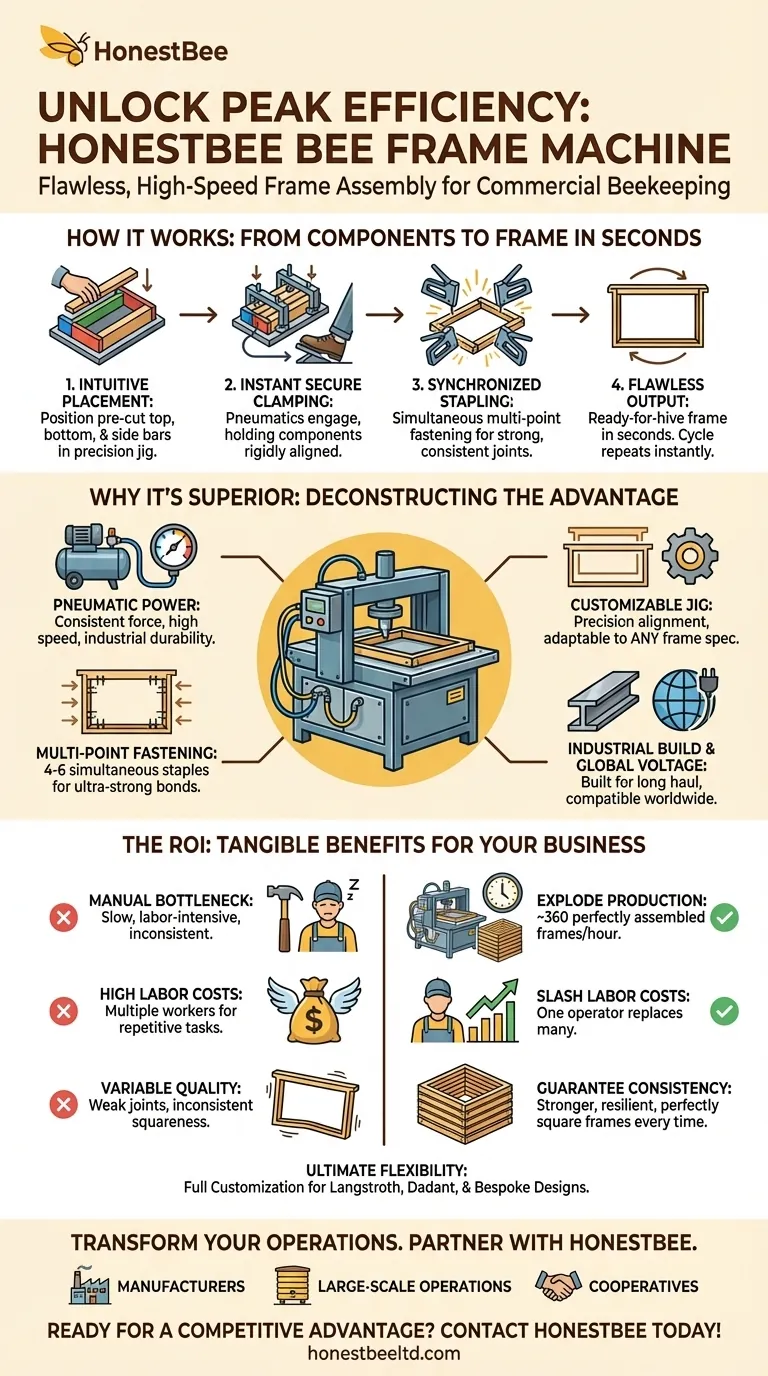

In the demanding world of commercial beekeeping and equipment supply, time is honey, and quality is king. The painstaking process of manually assembling and nailing thousands of bee frames can be a significant drain on resources, a bottleneck in production, and a source of inconsistent quality. Imagine transforming this labor-intensive task into a streamlined, high-speed operation that delivers perfectly square, robustly assembled frames every single time. This isn't just an improvement; it's a revolution in your workshop, brought to you by the HONESTBEE Bee Frame Machine: Frame Stapling Machine.

This isn't merely a tool; it's a strategic investment engineered to significantly reduce your labor costs, skyrocket your output, and elevate the quality of your bee frames, whether you're crafting Langstroth, Dadant, or any custom specification.

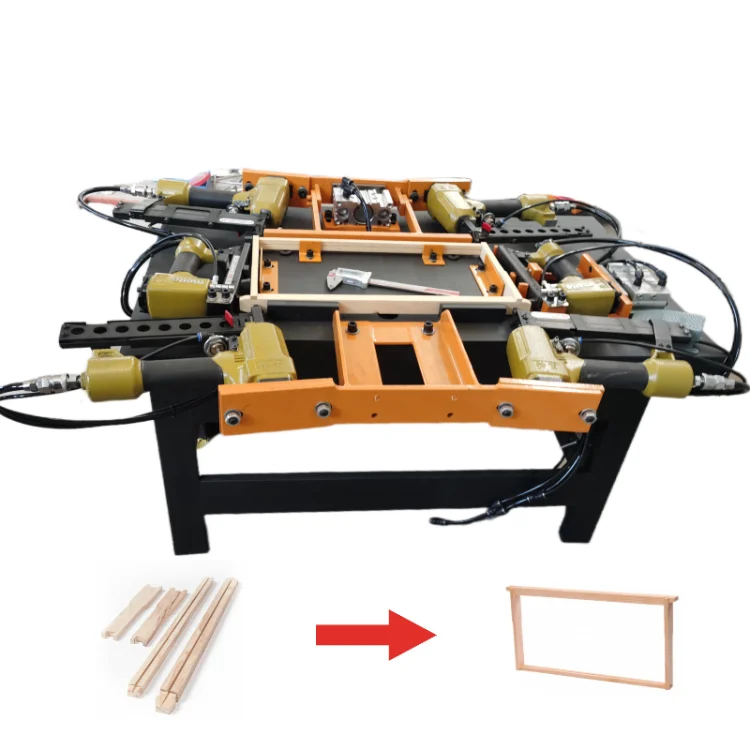

From Components to Complete Frames in Seconds: A Look at the Powerhouse in Action

- Intuitive Component Placement: The operator easily positions pre-cut wooden top bars, bottom bars, and side bars into the brightly colored, precision-engineered jig. This jig is the heart of the machine's accuracy, ensuring perfect alignment.

- Instant Secure Clamping: With a simple activation (a foot pedal for hands-free operation), a network of pneumatic clamps engages instantly, holding every component rigidly in place. This eliminates any movement or misalignment during the critical fastening stage.

- Synchronized, Powerful Stapling: Strategically mounted pneumatic staple guns fire simultaneously, driving multiple U-shaped staples deep into the frame joints. This action is swift, precise, and delivers consistent pressure for an incredibly strong bond.

- Flawless Output, Ready for the Hive: In mere seconds, a perfectly assembled, square, and robust bee frame is ready. The operator removes it, and the machine is immediately prepared for the next cycle.

Deconstructing the Advantage: Why the HONESTBEE Bee Frame Machine Excels

Understanding the engineering behind this machine reveals why it's a superior solution for serious bee frame production:

- The Might of Pneumatics: This bee frame machine harnesses the reliable power of compressed air. Pneumatic systems are known for their:

- Consistent Force: Delivering the same stapling power every time, unlike manual nailing where fatigue can lead to variations.

- Speed: Rapid cycling for high-speed assembly.

- Durability: Pneumatic tools are built for industrial environments and offer a long operational life with proper maintenance.

- The Genius of the Customizable Jig: This isn't a one-size-fits-all compromise.

- Precision Alignment: Ensures every frame is perfectly square and components are accurately positioned.

- Adaptability is Key: We will custom-design and build the jig to your exact frame specifications. Whether you produce Langstroth (deep, medium, or shallow), Dadant, British Standard, National, Smith, or even a completely unique proprietary frame design, your HONESTBEE bee frame machine will be tailored to fit. This is a core advantage that sets our machine apart.

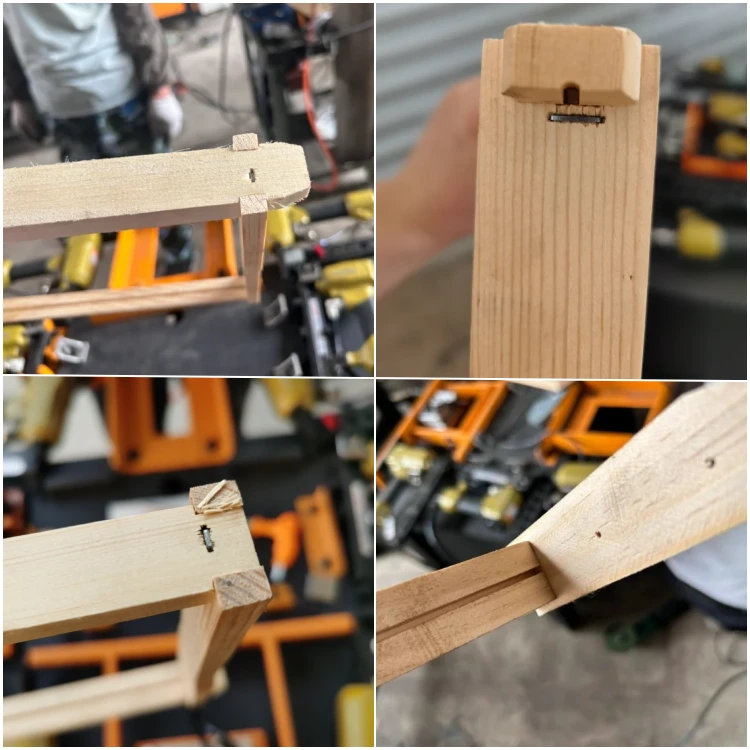

- Multi-Point, Synchronized Fastening:

- Simultaneous Stapling: By firing multiple staples at once (configurable for 6 or 4 U-shaped staples per frame), the machine secures all critical joints in a single, ultra-fast operation. This eliminates the need to rotate the frame or fasten joints individually.

- Strategic Placement: Staplers are positioned for optimal joint strength, often at an angle to maximize holding power and prevent splitting.

- Engineered for the Long Haul:

- Industrial-Grade Construction: A robust steel frame, high-quality pneumatic components, and durable fittings mean this machine is built to withstand the rigors of continuous, high-volume operation.

- Professional Finish: The clean lines, organized pneumatic hosing, and durable paint finish not only look professional but also contribute to easier maintenance and longevity.

- Global Electrical Compatibility: While the standard is single-phase 220V, we understand global needs. We will customize the machine for single-phase 110V or other specific voltages based on your local requirements.

Transforming Your Operations: The Tangible Benefits

Investing in the HONESTBEE Pneumatic Bee Frame Machine isn't an expense; it's a pathway to significant operational gains:

- Explode Your Production Capacity:

- The Problem Solved: Manual assembly is a major bottleneck.

- The HONESTBEE Solution: Achieve an output of approximately 360 perfectly assembled frames per hour. This allows you to meet peak season demands, fulfill large orders promptly, and scale your business without proportionally increasing your workforce.

- Slash Labor Costs, Boost Profitability:

- The Problem Solved: High labor input for a repetitive task.

- The HONESTBEE Solution: One operator can achieve the output of several manual assemblers. This translates directly to lower labor costs per frame and a healthier bottom line.

- Guarantee Uncompromising Quality & Consistency:

- The Problem Solved: Manual nailing leads to variations in squareness, staple depth, and overall strength.

- The HONESTBEE Solution: Every frame is a perfect replica. Consistent squareness means easier hive management and better comb building by bees. Uniform staple placement ensures lasting durability. This quality reflects positively on your brand.

- Produce Stronger, More Resilient Frames:

- The Problem Solved: Weak joints lead to frame failure during inspections or extraction.

- The HONESTBEE Solution: Pneumatically driven staples provide superior holding power compared to manual nailing, resulting in frames that can endure years of use and the stresses of honey harvesting.

- Ultimate Flexibility with Full Customization:

- The Problem Solved: Needing different machines or complex changeovers for various frame types.

- The HONESTBEE Solution: As emphasized, this bee frame machine is built around your needs. From Langstroth deeps to Dadant shallows, from standard Hoffman sidebars to custom end bar profiles, we tailor the machine for seamless production. This makes you agile and responsive to diverse market demands.

(Image: A close-up of different types of wood joints on bee frames (e.g., butt joint, rabbet joint if applicable to the frames being stapled), with text "Strong, Precise Joints, Every Time.")

Operational Know-How: Using Your HONESTBEE Bee Frame Machine

While designed for simplicity, understanding the operation ensures optimal performance and safety:

- Preparation:

- Ensure your wooden frame components (top bars, bottom bars, side bars) are accurately pre-cut to your specifications.

- Connect the machine to a suitable air compressor capable of delivering ≥0.7 Mpa of consistent pressure.

- Load the pneumatic staple guns with the appropriate size and type of U-shaped staples for your wood and frame design.

- Assembly Process:

- Place the side bars into their designated slots in the jig.

- Position the top bar and bottom bar onto the side bars within the jig.

- Activate the machine. The pneumatic clamps will secure the components.

- The staple guns will automatically fire, securing all joints.

- Release the clamps and remove the fully assembled frame.

- Repeat.

- Safety First:

- Always wear appropriate Personal Protective Equipment (PPE), including safety glasses. Hearing protection may also be advisable in a busy workshop.

- Ensure all guards are in place.

- Keep hands clear of the clamping and stapling mechanisms during operation.

- Familiarize yourself with the emergency stop features.

- Maintenance:

- Regularly drain any moisture from your air compressor and air lines.

- Keep the machine clean from sawdust and debris.

- Occasionally lubricate pneumatic staplers as per their manufacturer's recommendations.

- Inspect staple guns for wear and ensure they are functioning correctly.

- HONESTBEE provides support for spare parts and accessories to ensure the longevity of your investment.

Why the HONESTBEE Machine Outperforms Other Methods

- Manual Nailing: Extremely slow, labor-intensive, high inconsistency, physically demanding. Not viable for commercial scale.

- Individual Power Nailers/Staplers (without a jig): Faster than manual, but still prone to misalignment, requires significant skill for consistency, and is much slower than an integrated system.

- Basic Jigs with Manual Fastening: Improves alignment but doesn't offer the speed or consistent fastening power of a fully pneumatic system.

- The HONESTBEE Pneumatic Bee Frame Machine: An integrated, specialized solution that combines precise clamping with simultaneous, powerful pneumatic stapling. It's purpose-built for high-speed, high-quality, and high-volume bee frame assembly, making it the superior choice for professionals.

Is the HONESTBEE Pneumatic Bee Frame Machine Your Next Strategic Advantage?

If your business involves producing bee frames in quantity, and you're looking to enhance efficiency, quality, and profitability, the answer is a resounding YES. This bee frame machine is specifically for:

- Commercial Beekeeping Equipment Manufacturers & Suppliers: Drastically increase your production capacity and offer consistently superior frames.

- Large-Scale Beekeeping Operations: Gain control over your frame supply, reduce long-term costs, and ensure you always have quality frames ready.

- Beekeeping Cooperatives: Provide an invaluable resource for members to produce frames efficiently.

Don't Let Inefficient Assembly Limit Your Growth. Partner with HONESTBEE.

The HONESTBEE Pneumatic Bee Frame Machine: Frame Stapling Machine is more than just equipment; it's a commitment to excellence, efficiency, and the success of your beekeeping enterprise. As your trusted wholesale supplier, we are dedicated to providing robust, customizable, and high-performance solutions.

Ready to transform your bee frame production from a chore into a competitive advantage? Contact HONESTBEE today! Let's discuss your unique frame requirements – whether for Langstroth, Dadant, British Standard, or bespoke designs – and configure the perfect, high-efficiency bee frame machine solution to drive your business forward.

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

Related Articles

- How Beehive Frame Making Machines Enhance Apiary Productivity and Hive Longevity

- How the Beehive Frame Machine Transforms Apiary Equipment Production

- Beyond the Hammer: The Psychological Calculus of a Bee Frame Machine

- Scaling Up Your Beekeeping Operation: How an HonestBee Bee Frame Machine Fuels Growth

- Mastering Bee Frame Production: A Factory-Scale Guide with Advanced Bee Frame Machine Solutions