Modern beekeeping demands efficiency without compromising the natural needs of honeybee colonies. For commercial apiaries and equipment distributors, investing in specialized machinery like beehive frame making machines isn’t just about speed—it’s about precision, durability, and long-term cost savings. This article explores how these machines optimize frame production, improve hive performance, and deliver measurable returns for large-scale operations.

Optimizing Beehive Frame Production with Precision Engineering

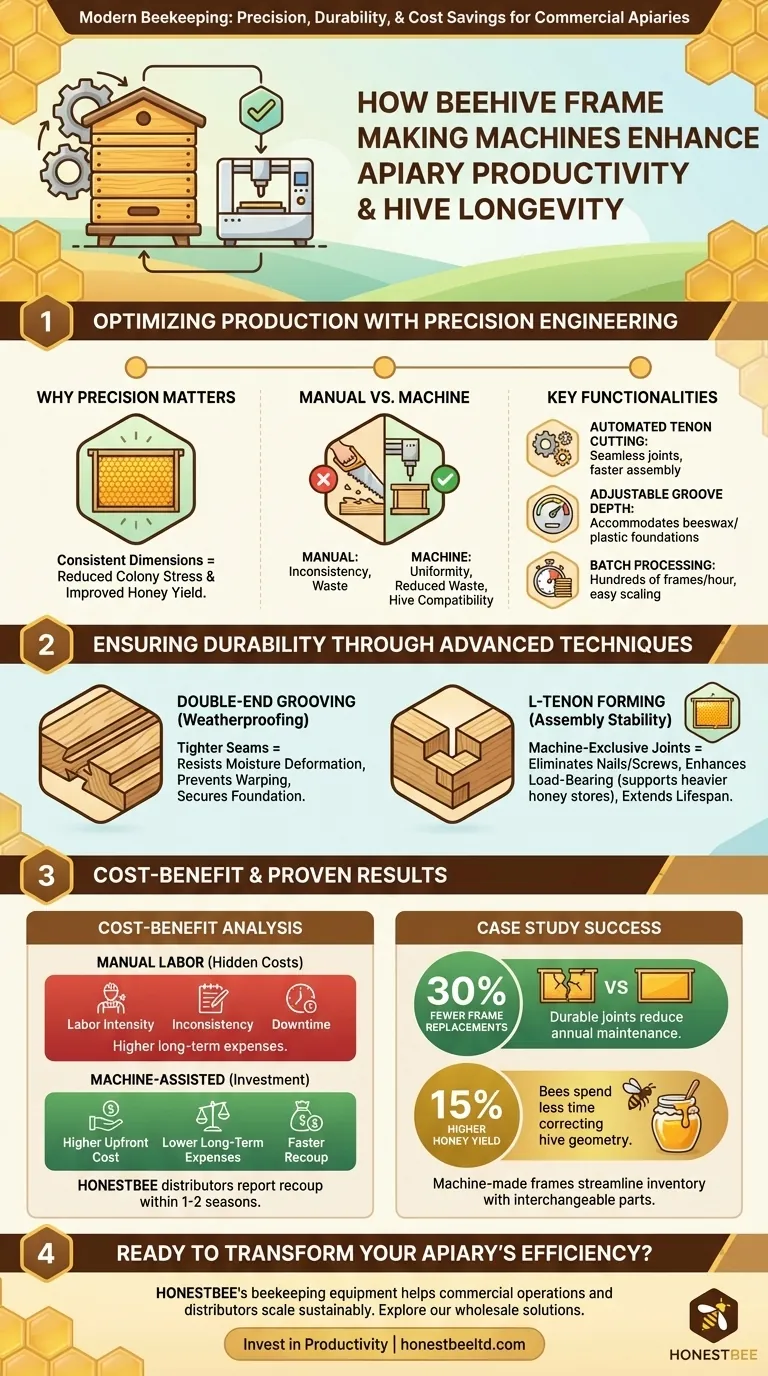

Why Precision Matters in Beehive Frame Manufacturing

Beehive frames are the backbone of a healthy colony. Ill-fitting or irregular frames disrupt hive organization, forcing bees to expend energy repairing gaps or building excess burr comb. Research shows that consistent frame dimensions reduce colony stress and improve honey yield.

Manual frame production often leads to minor variances in wood joints, while machines ensure:

- Uniformity: Every frame matches Langstroth or other standard hive dimensions.

- Reduced Waste: Automated cutting minimizes material errors.

- Hive Compatibility: Interchangeable parts simplify equipment management for large apiaries.

Key Functionalities and Their Impact on Hive Performance

Modern frame making machines integrate features like:

- Automated Tenon Cutting: Creates seamless joints for faster assembly.

- Adjustable Groove Depth: Accommodates different foundation types (e.g., beeswax vs. plastic).

- Batch Processing: Produces hundreds of frames per hour, ideal for commercial scaling.

For beekeepers using traditional beeswax foundations—the preferred choice for its eco-friendliness and bee adaptability—machine-made frames ensure foundations snap in securely, reducing mid-season repairs.

Cost-Benefit Analysis: Manual vs. Machine-Assisted Production

While manual labor suits small-scale operations, commercial apiaries face hidden costs:

- Labor Intensity: Hand-cutting frames requires skilled workers and time.

- Inconsistency: Even minor errors accumulate across thousands of frames.

- Downtime: Bees may abandon poorly built frames, delaying honey flows.

Machines offset these issues with higher upfront costs but lower long-term expenses. Distributors like HONESTBEE report that apiaries recoup investments within 1–2 seasons through improved productivity.

Ensuring Durability Through Advanced Woodworking Techniques

The Role of Double-End Grooving in Weatherproofing Frames

Hive frames endure humidity, temperature swings, and propolis buildup. Double-end grooving—a machine-exclusive technique—creates tighter seams between wood components, preventing:

- Warping: Grooves lock joints to resist moisture deformation.

- Foundation Slippage: Beeswax stays firmly embedded season after season.

How L-Tenon Forming Improves Frame Assembly Stability

L-tenons (interlocking wood joints) are nearly impossible to craft manually at scale. Machine-formed tenons:

- Eliminate Nails/Screws: Reduce hive contaminants and splinter risks.

- Enhance Load-Bearing: Support heavier honey stores without sagging.

Wooden frames remain the gold standard for repairability, and machine precision extends their lifespan by years.

Case Studies: Success Stories from Commercial Beekeepers

A Midwest apiary using HONESTBEE’s equipment saw:

- 30% Fewer Frame Replacements: Durable joints reduced annual maintenance.

- 15% Higher Honey Yield: Bees spent less time correcting hive geometry.

Another distributor noted that machine-made frames streamlined inventory for clients, as all components were reliably interchangeable.

Ready to Transform Your Apiary’s Efficiency?

HONESTBEE’s beekeeping equipment helps commercial operations and distributors scale sustainably. Explore our wholesale solutions to invest in productivity that benefits both your business and the bees.

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

Related Articles

- How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges

- Mastering Bee Frame Production: A Factory-Scale Guide with Advanced Bee Frame Machine Solutions

- Beyond the Hammer: The Psychological Calculus of a Bee Frame Machine

- How to Make Bee Frames in a Factory: The Ultimate Guide to High-Volume Production with HONESTBEE Bee Frame Machines

- How the Beehive Frame Machine Transforms Apiary Equipment Production