Yes, you can absolutely use a wax melter for beeswax, but the term "wax melter" covers several distinct methods. The critical factor is not the device itself, but its ability to provide gentle, indirect heat. Using the wrong type of heat can scorch the wax or, more dangerously, bring it to its flashpoint.

The most important principle for melting beeswax is using slow, indirect heat to preserve its quality and prevent a fire hazard. The best "melter" is simply the tool that achieves this safely for your specific volume of wax, whether it's a double boiler, a crock pot, or a solar melter.

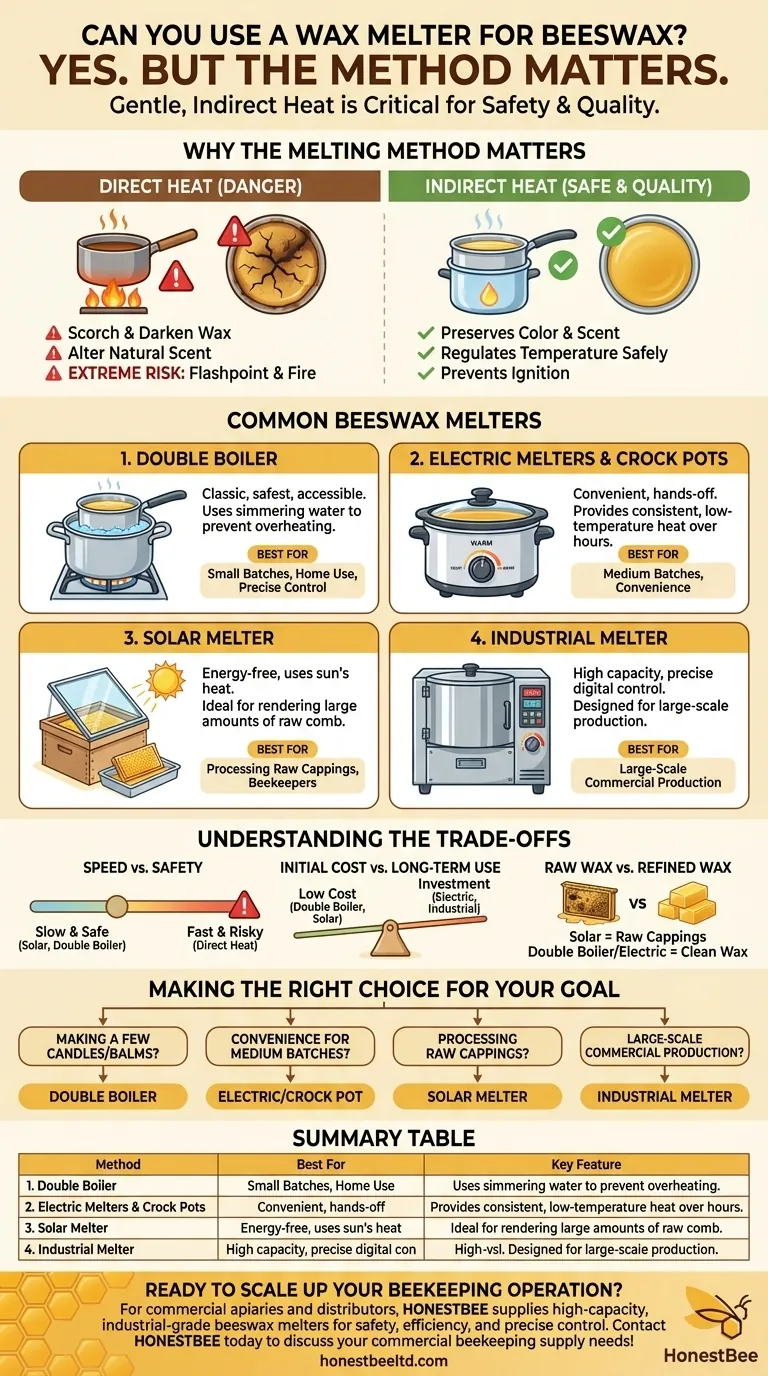

Why the Melting Method Matters

Beeswax is a natural and flammable material. How you melt it directly impacts both safety and the quality of your final product.

The Dangers of Direct Heat

Applying high, direct heat (like placing a pot directly on a stove burner) is extremely risky. Beeswax has a flashpoint, a temperature at which its vapors can ignite. Using indirect heat methods keeps the temperature safely regulated.

Preserving Wax Quality

Overheating can also scorch and darken the beeswax, altering its natural color and subtle honey scent. Gentle heat preserves these desirable qualities, which is especially important for products like candles and cosmetics.

Common Types of Beeswax Melters

The right tool depends on your goal, from making a single candle to processing large quantities of raw cappings from a beehive.

The Double Boiler Method

This is the classic, safest, and most accessible method for small-scale melting. By placing a smaller pot with wax inside a larger pot of simmering water, you ensure the wax never exceeds the boiling point of water (212°F / 100°C). This provides perfect temperature control.

Electric Melters and Crock Pots

Dedicated electric wax melters or standard kitchen crock pots are excellent for convenience. They provide slow, consistent, and low-temperature heat over several hours. Simply set the device to its "warm" or "low" setting for a safe and hands-off process.

Solar Melters

A solar melter is a simple, energy-free device ideal for beekeepers looking to render and clarify large amounts of raw comb or cappings. It uses the sun's heat inside an insulated box to gently melt the wax, which then drips through a filter and is collected in a clean tray. This is a slow but very effective method for processing impure wax.

Industrial Melters

For large-scale commercial operations, industrial-grade melters offer high capacity and precise digital temperature regulation. They are designed for efficiency and safety when handling significant volumes of beeswax for production.

Understanding the Trade-offs

Choosing a method involves balancing speed, convenience, and the scale of your project.

Speed vs. Safety

Faster melting almost always involves higher, more dangerous heat. Methods like solar melting are very slow but incredibly safe. A double boiler offers a moderate speed with excellent safety. Never sacrifice safety for speed.

Initial Cost vs. Long-Term Use

A double boiler setup can be improvised with existing kitchen equipment for no cost. A crock pot or dedicated electric melter is a modest investment for added convenience, especially if you melt wax regularly.

Raw Wax vs. Refined Wax

Solar melters excel at the initial, messy job of separating raw wax from honey and debris. Double boilers and crock pots are better suited for re-melting clean, refined blocks of wax for projects like candle making.

Making the Right Choice for Your Goal

Select your method based on the task at hand to ensure a safe and successful outcome.

- If your primary focus is making a few candles or balms at home: Use the double boiler method for its unmatched safety and control with small batches.

- If your primary focus is convenience for medium-sized batches: An electric crock pot or dedicated wax melter will streamline your process.

- If your primary focus is processing raw cappings from your beehives: A solar melter is the most efficient and economical tool for the job.

- If your primary focus is large-scale commercial production: Invest in an industrial beeswax melter designed for volume and precise temperature control.

By understanding the principles of indirect heat, you can confidently choose the right tool to master the process safely.

Summary Table:

| Method | Best For | Key Feature |

|---|---|---|

| Double Boiler | Small Batches, Home Use | Safest, Precise Temp Control |

| Electric/Crock Pot | Medium Batches, Convenience | Hands-off, Consistent Low Heat |

| Solar Melter | Processing Raw Cappings | Energy-free, Ideal for Beekeepers |

| Industrial Melter | Large-Scale Production | High Capacity, Digital Control |

Ready to scale up your beekeeping operation?

For commercial apiaries and beekeeping equipment distributors, HONESTBEE supplies high-capacity, industrial-grade beeswax melters designed for safety, efficiency, and precise temperature control. Our wholesale-focused operations ensure you get the professional equipment you need to process large volumes of wax reliably.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs!

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- How to permanently decrystallize honey? Embrace Its Natural State for Maximum Quality

- At what temperature does honey flow? Preserve Quality with the Perfect 95°F Sweet Spot

- Why is it important to heat honey slowly and evenly? Preserve Flavor, Nutrients & Value

- What are the negative effects of overheating honey? Preserve Your Honey's Natural Quality

- What is melter honey used for? A Low-Cost Ingredient for Bakers and Brewers