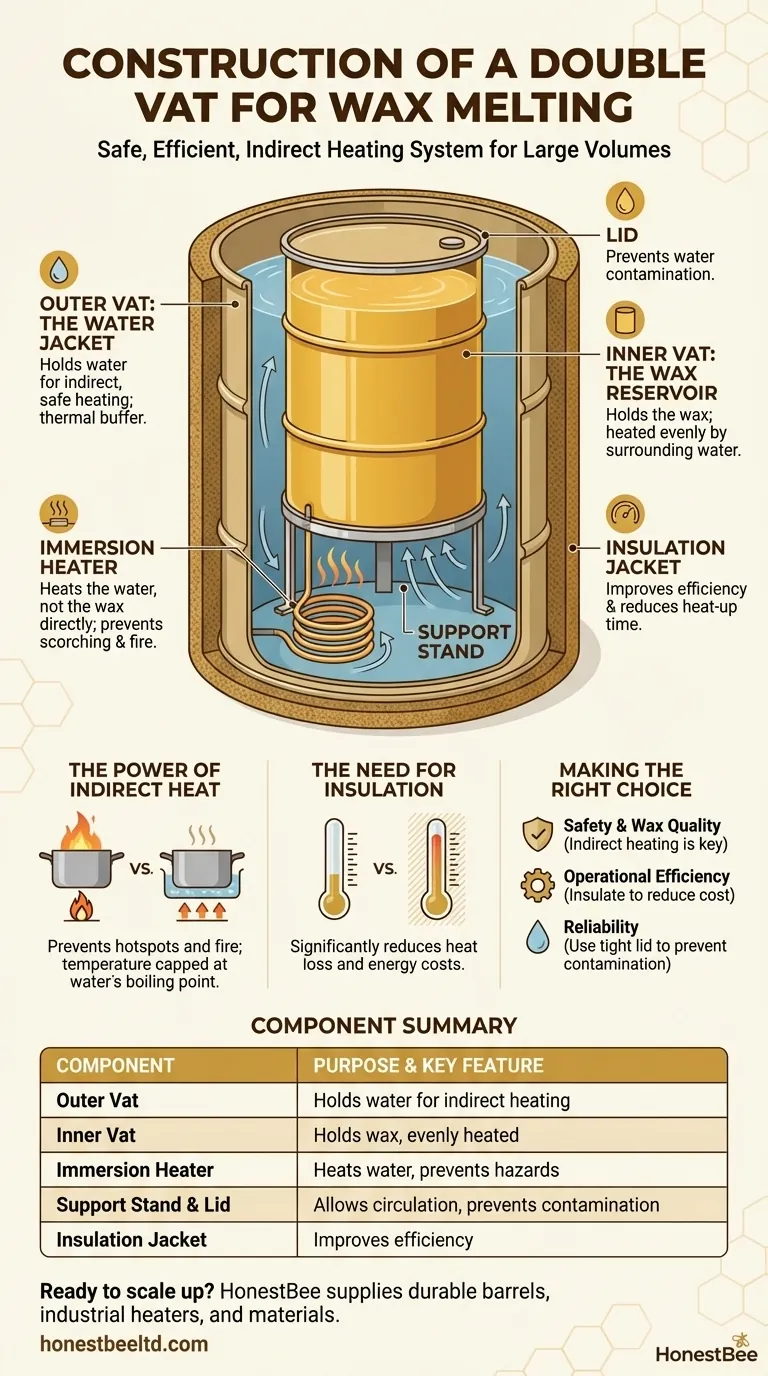

At its core, a double vat for melting wax is a purpose-built double boiler system designed for large volumes. It consists of a smaller barrel for the wax mounted inside a larger barrel that holds a heated water bath. This construction provides gentle, indirect heat, which is essential for safely melting wax without scorching it or creating a fire hazard.

The fundamental purpose of the double-vat design is not just to melt wax, but to control the heat transfer precisely. By heating a surrounding water jacket, you ensure the wax melts evenly and safely, avoiding the dangerous hotspots and fire risks associated with direct heating.

Deconstructing the Double Vat System

Understanding the role of each component is key to appreciating why this design is so effective for processing large quantities of wax. The entire system is built around the principle of creating a controlled, indirect heat source.

The Outer Vat: The Water Jacket

The foundation of the system is the outer barrel, typically a 15-gallon drum approximately 27 inches high with a 14.5 to 15-inch wide top.

This larger vat's sole purpose is to hold water, creating a "water jacket" around the inner wax container. It acts as a thermal buffer, absorbing the intense, direct energy from the heat source.

The Heating Element: The Immersion Heater

An electric immersion heater is installed near the bottom of the outer vat.

Placing the heater in the water—and never in the wax itself—is the most critical aspect of this design. It heats the water, which in turn gently and uniformly heats the inner vat through convection and conduction.

The Inner Vat: The Wax Reservoir

A smaller barrel, usually 7.5 to 8 gallons (20-22 inches high, 10-inch top), is placed inside the outer vat. This is where the wax is actually held.

This inner container is never directly exposed to the heating element. Its entire surface is heated evenly by the surrounding hot water, preventing the wax from burning.

The Support Stand and Lid

A simple 5-inch tall stand, often made from a sturdy metal bucket, is placed at the bottom of the outer vat. This stand elevates the inner barrel, allowing water to circulate freely underneath it for consistent heating from all sides.

The inner barrel must be covered with a tight-fitting metal lid. This prevents water condensation from dripping into the hot wax, which could cause dangerous spattering and contaminate your final product.

Key Principles for Efficiency and Safety

The specific components are less important than the principles they serve. A safe and effective system prioritizes controlled heating, insulation, and the separation of water from wax.

The Power of Indirect Heat

This entire construction is an up-scaled version of a standard double boiler. Direct heat is difficult to control and can easily create hotspots that exceed the flash point of wax, leading to scorching or fire.

By heating the water first, you create a large thermal mass that transfers heat slowly and evenly. The temperature of the wax can never exceed the boiling point of water (212°F / 100°C), keeping the process well within a safe operating range.

The Need for Insulation

To improve performance and reduce energy costs, the exterior of the large vat is wrapped in a hot-water heater jacket.

Without insulation, a significant amount of energy is lost to the surrounding air. An insulating jacket dramatically reduces this heat loss, allowing the vat to reach and maintain its target temperature faster and with less electricity.

Understanding the Trade-offs

While highly effective, this design has practical considerations you must account for.

Slower Heat-Up Times

Safety comes at the cost of speed. Indirect heating is inherently slower than applying a direct flame. You must plan for the significant time it takes to heat the large volume of water before the wax even begins to melt.

Water Level Management

The water in the outer vat will evaporate over time. You must monitor and maintain the water level to ensure the immersion heater remains fully submerged. If the heater is exposed to air while operating, it can be damaged or pose a fire risk.

Construction and Sourcing

This is not an off-the-shelf product. It requires sourcing the correct size barrels and components and performing the assembly yourself. This requires a basic level of mechanical aptitude and access to the necessary parts.

Making the Right Choice for Your Goal

Building a double vat requires balancing safety, efficiency, and effort. Your primary goal should guide your construction choices.

- If your primary focus is safety and wax quality: The double-vat method of indirect heating is non-negotiable to prevent scorching and fire.

- If your primary focus is operational efficiency: Adding an external insulating jacket is the single most important step to reduce heat-up times and energy costs.

- If your primary focus is reliability and low maintenance: Ensuring the inner vat has a tight-fitting lid is crucial to prevent water contamination, a common source of problems in wax processing.

By understanding these core construction principles, you can build a robust system that provides safe, consistent, and high-quality results for your wax melting needs.

Summary Table:

| Component | Purpose & Key Feature |

|---|---|

| Outer Vat (Water Jacket) | Holds water for indirect, safe heating; typically a 15-gallon drum. |

| Inner Vat (Wax Reservoir) | Holds the wax; heated evenly by the water jacket; typically a 7.5-8 gallon barrel. |

| Immersion Heater | Heats the water, not the wax directly; prevents scorching and fire hazards. |

| Support Stand & Lid | Allows water circulation and prevents water contamination of the wax. |

| Insulation Jacket | Wraps the outer vat to improve efficiency and reduce heat-up time and energy costs. |

Ready to scale up your wax processing with professional-grade equipment?

Building a reliable, high-capacity double vat requires the right components for safety and efficiency. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable barrels, industrial immersion heaters, and insulating materials needed to construct a robust system.

Contact our experts today to discuss your specific needs and ensure your wax melting operation is built for maximum safety and productivity.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- What is the proper way to store processed beeswax? Expert Guide to Maintaining Wax Purity and Quality

- What are the methods for melting and clarifying beeswax? Safely Render Wax with Indirect Heat

- What is the biological safety value of using industrial wax melting equipment? Ensure Pathogen-Free Beeswax Recovery

- What is the best container to melt wax in? Choose the Safest Method for Your Project

- How should beeswax be melted? Safe Methods to Preserve Quality and Avoid Fire Hazards

- What are the environmental benefits of using a Solar Wax Melter? Achieve Zero-Emission Wax Processing

- Is there a single best method for cleaning raw beeswax? Find the Perfect Workflow for Your Apiary

- What are the technical advantages of using a solar wax melter? Master Premium Beeswax Extraction Today