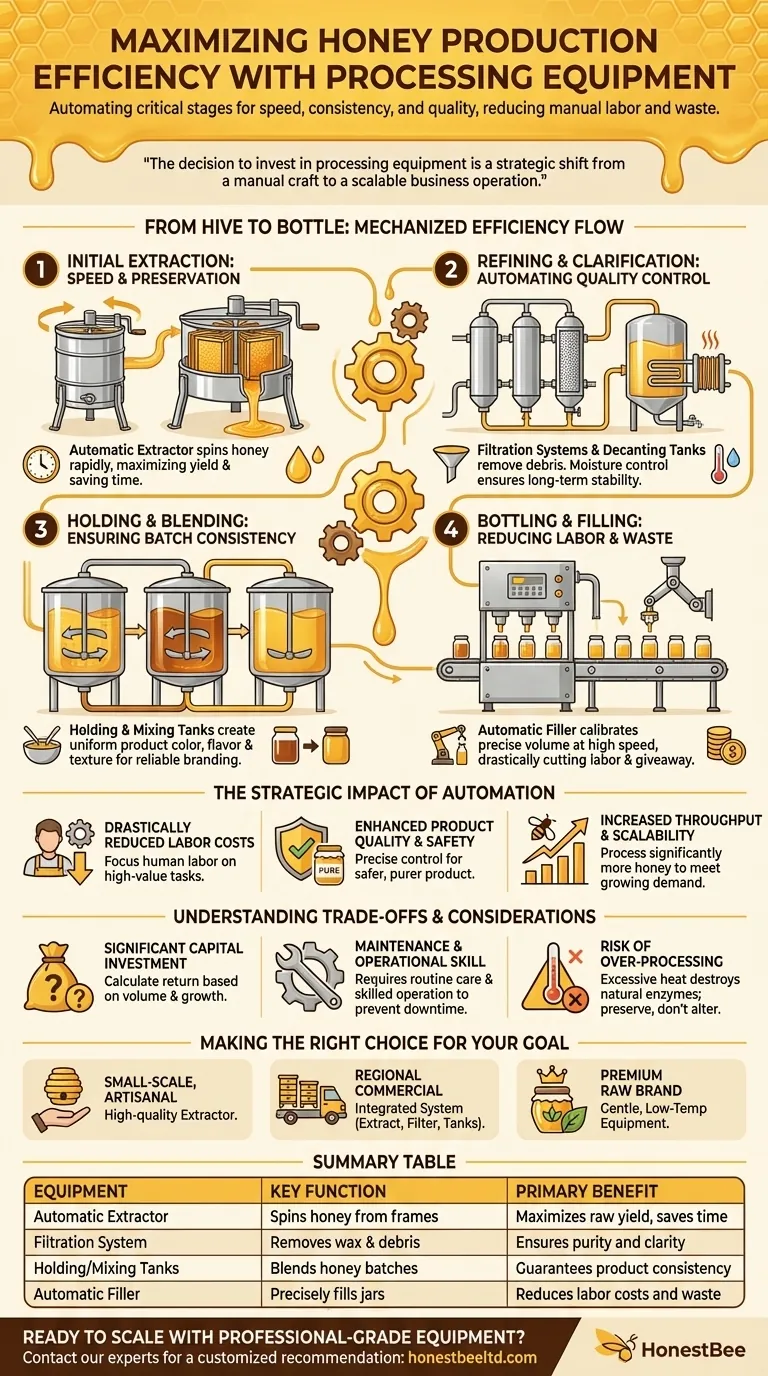

In short, honey processing equipment maximizes efficiency by automating the critical, labor-intensive stages of production. Specialized machinery for extraction, filtration, moisture control, and bottling allows you to produce more honey in less time, with greater consistency and higher quality, directly reducing manual labor and operational waste.

The decision to invest in processing equipment is a strategic shift from a manual craft to a scalable business operation. It's not just about producing more honey faster; it's about gaining precise control over product quality, consistency, and safety, which are the foundations of a profitable brand.

From Hive to Bottle: Key Stages of Mechanized Efficiency

Modern honey processing transforms a series of disconnected, manual tasks into a single, streamlined workflow. Each piece of equipment is designed to optimize a specific stage of the process, ensuring maximum yield and quality.

Initial Extraction: Speed and Preservation

An automatic honey extractor is the first major step in mechanization. Using centrifugal force, it spins honey out of the comb far more rapidly and completely than manual crushing or draining methods.

High-quality, corrosion-free stainless steel units ensure the honey is not contaminated. This initial speed is critical, as it sets the pace for the entire production line and maximizes the raw honey yield from each frame.

Refining and Clarification: Automating Quality Control

After extraction, honey contains impurities like wax particles, pollen, and other hive debris. Filtration systems and decanting tanks automate the removal of these solids.

Furthermore, equipment like heat exchangers or vacuum plants allows for precise control over the honey's moisture content. Lowering moisture to the industry standard (typically below 18%) is essential for preventing fermentation and ensuring long-term shelf stability, a task that is difficult and inconsistent to manage manually.

Holding and Blending: Ensuring Batch Consistency

Large holding and mixing tanks are crucial for creating a uniform final product. They allow producers to blend honey from different harvests to achieve a consistent color, flavor profile, and texture.

This homogenization is key to building a reliable brand. When customers buy your honey, they expect the same quality in every jar, and blending tanks make this consistency achievable at scale.

Bottling and Filling: Reducing Labor and Waste

Finally, automatic filling machines handle the last stage of the process. These systems can be calibrated to fill jars to a precise volume or weight at high speed, dramatically reducing the labor costs and product giveaway associated with manual bottling.

The Strategic Impact of Automation

Investing in this equipment goes beyond simple convenience. It fundamentally changes the economic model of your operation.

Drastically Reduced Labor Costs

Automation directly replaces the most repetitive and time-consuming manual tasks. This frees up human labor to focus on higher-value activities like apiary management, marketing, and quality assurance.

Enhanced Product Quality and Safety

Mechanized systems provide a level of precision that manual processing cannot match. Consistent filtration, moisture control, and adherence to sanitation standards result in a safer, purer, and more valuable product that builds consumer trust.

Increased Throughput and Scalability

The primary benefit is the ability to process significantly more honey in the same amount of time. This increased throughput is what allows a small operation to scale up to meet growing market demand without a proportional increase in labor or facility size.

Understanding the Trade-offs and Considerations

While the benefits are clear, a move to mechanization requires a clear-eyed assessment of the challenges.

Significant Capital Investment

Honey processing equipment represents a major upfront cost. The return on this investment must be carefully calculated based on your current production volume and growth projections.

Maintenance and Operational Skill

While reliable equipment minimizes interruptions, it does require routine maintenance and cleaning. Your team will need the skills to operate and care for the machinery to prevent costly downtime.

The Risk of Over-Processing

Improper use of equipment, especially heat exchangers, can damage the product. Excessive heat can destroy the delicate enzymes and aromas in raw honey, diminishing its quality and market value. It is critical to use equipment to preserve, not alter, the honey's natural characteristics.

Making the Right Choice for Your Goal

The right equipment depends entirely on the scale and ambition of your honey business.

- If your primary focus is small-scale, artisanal production: A high-quality stainless steel extractor is your most important first investment to improve efficiency without sacrificing quality.

- If you are scaling into a regional commercial operation: An integrated system including extraction, filtration, and holding tanks is necessary to ensure the batch consistency and safety required for retail markets.

- If your brand is built on premium, raw honey: Invest in gentle, low-temperature processing equipment that preserves the honey's natural enzymes and delicate flavor profile.

Ultimately, strategic investment in processing equipment is what transforms honey production from a labor-intensive craft into a streamlined and profitable business.

Summary Table:

| Equipment | Key Function | Primary Benefit |

|---|---|---|

| Automatic Extractor | Spins honey from frames | Maximizes raw yield, saves time |

| Filtration System | Removes wax & debris | Ensures purity and clarity |

| Holding/Mixing Tanks | Blends honey batches | Guarantees product consistency |

| Automatic Filler | Precisely fills jars | Reduces labor costs and waste |

Ready to scale your honey production with professional-grade equipment?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, efficient machinery needed to automate extraction, filtration, and bottling. Our wholesale-focused operations are designed to help you maximize yield, ensure consistent quality, and grow your business profitably.

Contact our experts today for a customized equipment recommendation to meet your production goals.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What should a beekeeper do after extracting honey from supers? A Guide to Harvest Management

- What are the main types of honey extractors? Choose the Right Model for Your Apiary

- What are some tips for using a honey extractor effectively? Maximize Your Honey Yield and Protect Your Comb

- Why is preserving honeycomb integrity important, and how do automated extractors help? Boost Hive Health & Honey Yields

- What equipment do you need to process honey? A Complete Guide for Every Scale of Operation