Resolving a film jam in a honey stick machine requires a methodical approach that addresses the immediate blockage and its underlying cause. The primary steps involve inspecting and cleaning the machine's sensors, clearing any physical obstructions from the film path, and verifying the alignment of the guide rollers. These actions address the most common failure points that lead to a halt in production.

A film jam is not simply a blockage to be cleared; it is a symptom of a deeper issue within the system. The most effective solution involves moving beyond the immediate fix to diagnose the root cause, whether it's related to sensors, mechanical alignment, or the film material itself.

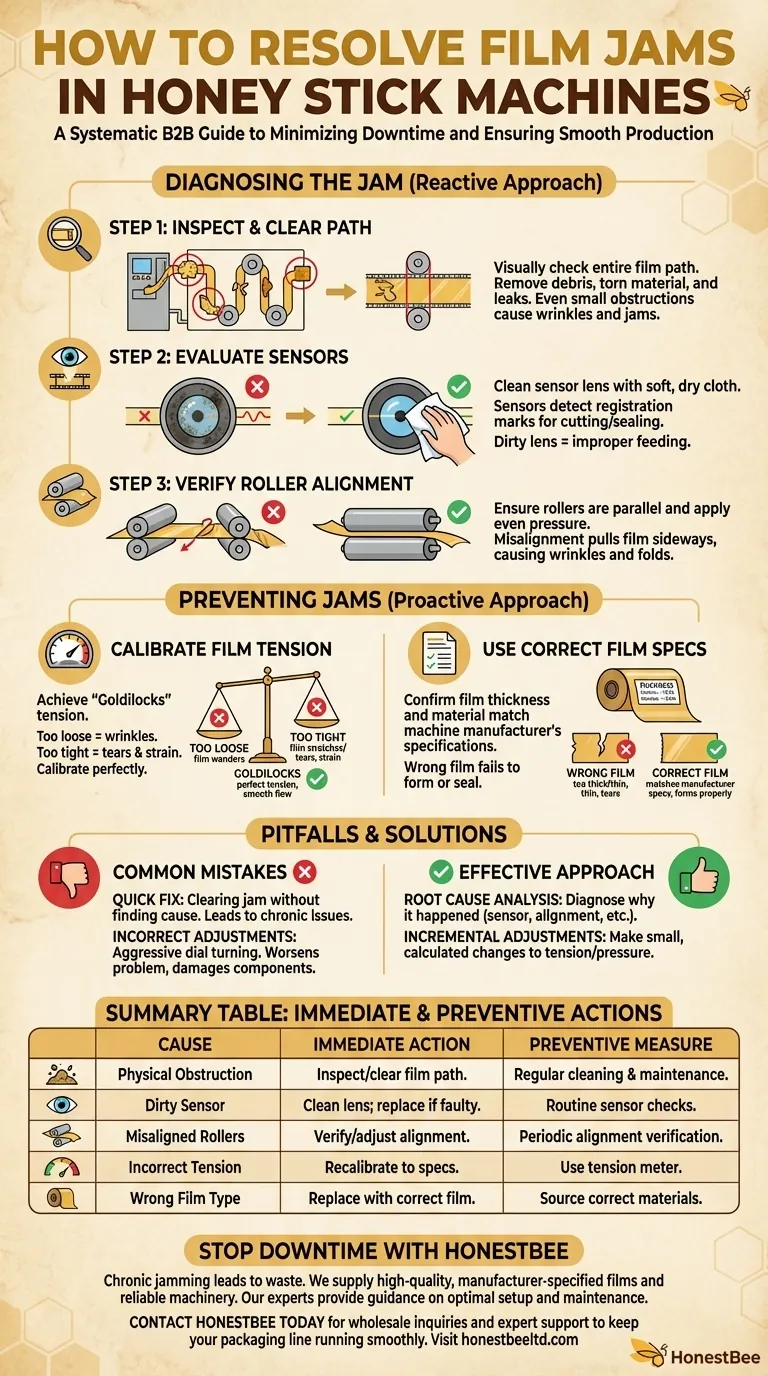

A Systematic Approach to Diagnosing Film Jams

To minimize downtime and prevent recurrence, it's crucial to diagnose the problem in a structured way rather than simply pulling out the jammed material. This process moves from the most likely and easiest-to-fix issues to more complex mechanical adjustments.

Step 1: Inspect the Film Path for Obstructions

The most direct cause of a jam is a physical blockage. Before making any adjustments, conduct a thorough visual inspection of the entire path the film travels.

Look for bunched-up film, pieces of torn material, or solidified honey that may have leaked. Carefully remove any debris, as even a small obstruction can cause the film to wrinkle and jam.

Step 2: Evaluate the Machine's Sensors

Honey stick machines rely on sensors, often an optical "eye-mark" sensor, to detect registration marks on the film and control the cutting and sealing process.

If the sensor's lens is dirty, it cannot read the mark correctly, causing the machine to stop or feed film improperly, leading to a jam. Clean the sensor lens gently with a soft, dry cloth. If jams persist despite a clean sensor, it may be malfunctioning and require replacement.

Step 3: Verify Roller Alignment

The rollers guide the film through the machine, from the unwinding roll to the forming and sealing station. Proper alignment is critical for smooth transit.

If the rollers are misaligned, they will pull the film to one side, causing it to wrinkle or fold over on itself, which inevitably leads to a jam. Ensure the rollers are parallel to each other and apply even, gentle pressure across the width of the film.

Preventing Jams Before They Start

Resolving jams is reactive. A proactive strategy focuses on calibration and material selection to ensure the machine runs smoothly from the start. This is the key to consistent, high-volume production.

The Critical Role of Film Tension

Film tension must be calibrated perfectly. It's a "Goldilocks" scenario where either extreme causes problems.

If the tension is too loose, the film can wander or wrinkle before it enters the forming tube, causing a blockage. If the tension is too tight, the film can stretch, tear, or put excessive strain on the machine's motors and seals.

Using the Correct Film Specifications

The machine is engineered to work with film of a specific thickness and material type. Using the wrong film is a common but often overlooked cause of operational issues.

Film that is too thick may not form or seal properly, while film that is too thin is prone to tearing and wrinkling under tension. Always confirm that the film you are using matches the specifications recommended by the machine's manufacturer.

Understanding the Pitfalls

In the rush to restart production, operators can make mistakes that either fail to solve the problem or create new ones. Understanding these common pitfalls is essential for effective troubleshooting.

Quick Fix vs. Root Cause Analysis

The most common mistake is clearing a jam without investigating why it happened. Simply pulling out the bunched-up film gets the machine running again, but it does not fix the misaligned roller or dirty sensor that will cause another jam minutes later. This leads to chronic downtime and material waste.

The Cost of Incorrect Adjustments

When faced with a jam, it can be tempting to start tightening dials for film tension or roller pressure. However, making aggressive adjustments without a clear diagnosis can worsen the problem. Over-tightening rollers can damage the film, while excessive tension can strain the machine's components. Always make small, incremental adjustments.

Making the Right Choice for Your Goal

Your immediate response should be tailored to your operational priority, whether it's getting the line running now or improving its long-term reliability.

- If your primary focus is resolving an immediate jam: Methodically check for physical blockages, clean the machine sensors, and visually inspect roller alignment.

- If your primary focus is preventing recurring jams: Calibrate your film tension carefully and verify you are using film with the correct thickness and material for your specific machine.

By shifting from reactive fixes to proactive diagnostics, you transform machine downtime into a reliable production asset.

Summary Table:

| Common Cause of Jam | Immediate Action | Preventive Measure |

|---|---|---|

| Physical Obstruction | Inspect and clear film path of debris. | Regular cleaning and maintenance. |

| Dirty/Malfunctioning Sensor | Clean sensor lens; replace if faulty. | Implement routine sensor checks. |

| Misaligned Rollers | Verify and adjust roller alignment. | Schedule periodic alignment verification. |

| Incorrect Film Tension | Recalibrate to manufacturer's specs. | Use a tension meter for precise setup. |

| Wrong Film Type | Replace with manufacturer-specified film. | Always source correct film materials. |

Stop Production Downtime Caused by Film Jams

Chronic jamming in your honey stick machines leads to wasted time, materials, and revenue. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, manufacturer-specified films and reliable machinery designed to work in harmony, drastically reducing the risk of blockages.

Our experts can help you select the right materials and provide guidance on optimal machine setup and maintenance. Ensure smooth, high-volume production and maximize your operational efficiency.

Contact HONESTBEE today for wholesale inquiries and expert support to keep your packaging line running smoothly.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What is the role of industrial honey filling equipment in enhancing honey export potential for international markets?

- How do automated honey filling and processing machines control Nosema disease? Enhance Biosecurity in Your Apiary

- What are the primary benefits of utilizing automated honey-filling machines? Scale Your Commercial Honey Processing

- What are the advantages of using an automatic honey filling machine? Ensure Superior Quality and Moisture Control

- What are the different types of filling mechanisms used in honey filling machines? Choose the Right Tech for Your Honey

- What role do honey filling machines play in enhancing the value of organic honey? Protect Purity and Scale Your Brand

- How do industrial-grade automated honey filling machines ensure product quality? 5 Key Benefits for Premium Honey Brands

- What is the process of a sachet filling machine? Optimize Your Packaging Line for Accuracy & Speed