At their core, automated honey extractors ensure consistent quality by applying a precise and uniform extraction speed. This controlled centrifugal force extracts honey evenly from the comb without generating excessive heat or shearing forces, which preserves the honey's delicate enzymes, flavor profile, and natural viscosity.

The true value of automation in honey production is not found in a single machine, but in an integrated system. Consistent quality is the result of controlled extraction, followed by automated filtering and packaging, which collectively minimize human variability and the risk of contamination.

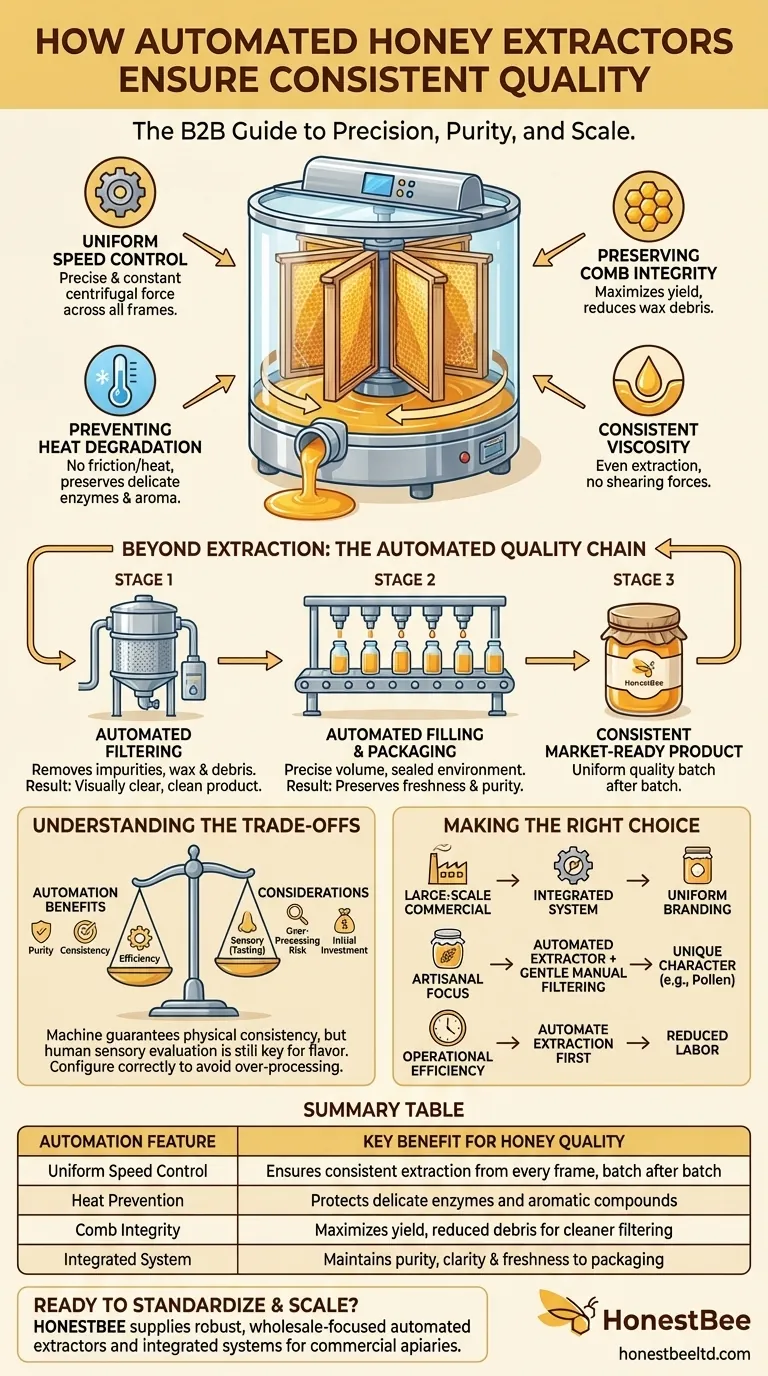

The Core Principle: Precision in Extraction

The extractor itself is the first and most critical step in achieving consistency. Its primary advantage over manual methods is the ability to eliminate variability in the force and duration applied to the honeycombs.

Uniform Speed Control

An automated extractor maintains a pre-set rotational speed. This ensures every frame is subjected to the same centrifugal force, resulting in a uniform extraction process batch after batch. This is foundational for creating a standard product.

Preventing Heat Degradation

Aggressive or inconsistent manual cranking can generate friction and heat, which can degrade the sensitive enzymes and aromatic compounds in raw honey. Automation applies force smoothly and efficiently, protecting the honey’s natural quality.

Preserving Comb Integrity

By gradually ramping up to and maintaining an optimal speed, automated systems can extract the maximum amount of honey without shattering the delicate wax comb. This not only increases yield but also reduces the amount of wax debris that needs to be filtered out later.

Beyond Extraction: The Automated Quality Chain

While the extractor is key, achieving true market-ready consistency involves automating the entire workflow. The quality gained in extraction can be lost in subsequent steps if they are not handled with equal precision.

The Role of Automated Filtering

After extraction, honey is often passed through an automated filtering machine. This removes impurities such as wax particles, bee parts, and other debris. The result is a visually clear, clean product with a consistent texture free of unwanted particles.

Ensuring Purity with Automated Filling

The final stage is packaging, where honey filling machines play a critical role. These systems provide a clean, sealed environment for bottling. They ensure precise fill volumes and minimize the honey's exposure to air and potential contaminants, preserving its freshness and purity right up to the point of sale.

Understanding the Trade-offs

Automation offers tremendous benefits for consistency, but it is not without considerations. Understanding the limitations is key to using the technology effectively.

Automation vs. Sensory Evaluation

A machine can guarantee physical consistency—purity, clarity, and viscosity—but it cannot taste the honey. Quality control for flavor and aroma remains a human task. Automation ensures the baseline is consistent, while sensory tasting confirms the final product quality.

The Risk of Over-Processing

Poorly configured automation can be detrimental. For example, using filters that are too fine can strip honey of beneficial pollen particles, removing the unique character of its floral source. Similarly, setting extraction speeds too high can still introduce heat and shear.

Initial Investment and Scale

The primary barrier to a fully automated system is the significant capital investment. For small-scale, artisanal beekeepers, the cost may outweigh the benefits if their goal is not mass-market uniformity but rather showcasing the unique variability of each harvest.

Making the Right Choice for Your Goal

The level of automation you should adopt depends entirely on your production goals.

- If your primary focus is large-scale commercial branding: An integrated system of extraction, filtering, and filling is essential to deliver the uniform product consumers expect.

- If your primary focus is preserving artisanal character: A high-quality automated extractor is key, but you may choose more gentle, manual filtering to retain unique properties like high pollen content.

- If your primary focus is improving operational efficiency: Automating the extraction process first offers the most significant reduction in manual labor for most small to medium-sized operations.

Ultimately, automation provides you with precise control over the variables that determine honey's physical quality, freeing you to focus on producing the best possible product.

Summary Table:

| Automation Feature | Key Benefit for Honey Quality |

|---|---|

| Uniform Speed Control | Ensures consistent extraction from every frame, batch after batch. |

| Heat Prevention | Protects delicate enzymes and aromatic compounds from degradation. |

| Comb Integrity Preservation | Maximizes yield and reduces wax debris for cleaner filtering. |

| Integrated Filtering & Filling | Maintains purity, clarity, and freshness from extraction to packaging. |

Ready to standardize your honey quality and scale your operation? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, wholesale-focused automated honey extractors and integrated systems. Our equipment delivers the precise control you need to ensure every batch meets your highest standards for purity and consistency. Contact our experts today to discuss a solution tailored for your production goals.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 8 Frame Electric and Manual Three Use Honey Extractor

People Also Ask

- Why is a professional honey extraction room essential? Secure Pure Quality & Market Success

- What is the importance of transitioning to modern honey extraction equipment? Scale Your Commercial Apitherapy Success

- How long does it take to extract a frame of honey? A realistic guide to harvest time.

- What was the traditional method for honey extraction, and what were its drawbacks? Efficiency vs. Heritage

- What is the working principle of industrial Honey Extractors? Boost Yield with Advanced Centrifugal Technology

- How does a centrifugal honey extractor assist in measuring the nectar collection efficiency of a bee colony?

- What are the benefits of using industrial high-capacity honey centrifuges in professional apiaries? Maximize Yields

- What are the advantages of high-performance honey extraction complexes? Maximize yield and efficiency for large apiaries.