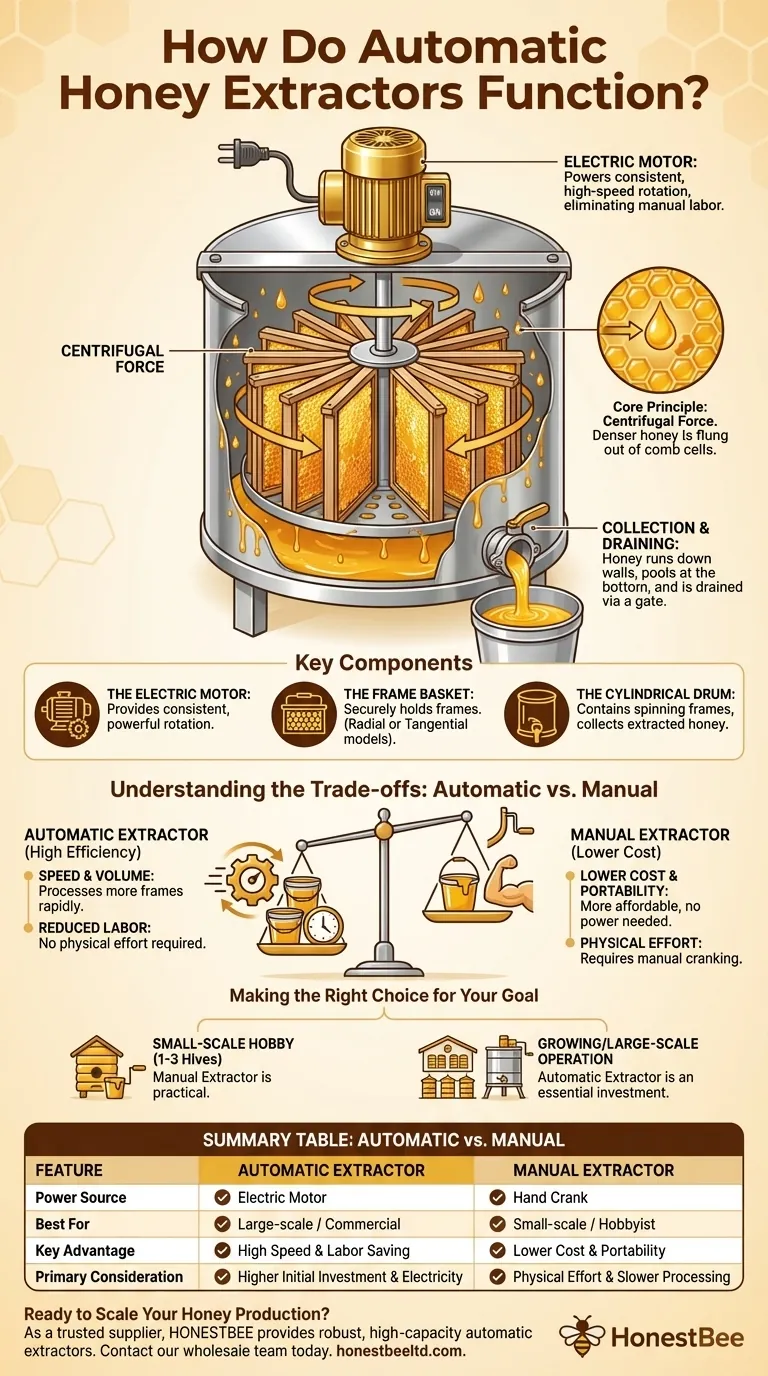

At its core, an automatic honey extractor uses an electric motor to automate the process of separating honey from the comb. It places prepared honey frames into a basket inside a large drum, which is then spun at high speed, using centrifugal force to pull the honey out and onto the inner walls of the container for collection.

The essential function of an automatic extractor is to leverage an electric motor to apply consistent centrifugal force, dramatically increasing the speed and efficiency of honey harvesting while eliminating the physical labor required by manual methods.

The Core Principle: Centrifugal Force

At the heart of every honey extractor, whether manual or automatic, is the simple yet powerful principle of centrifugal force. Understanding this concept is key to understanding how the machine works.

How Spinning Separates Honey

An automatic extractor operates much like a washing machine's spin cycle. The electric motor spins a central basket holding the honey frames at a very high speed. This rapid rotation creates a powerful outward force.

Since honey is denser than the wax comb, this force flings the liquid honey away from the center, causing it to exit the individual comb cells.

The Role of the Drum

The entire spinning mechanism is housed within a large, typically stainless steel, cylindrical drum. As the honey is flung from the comb, it hits the interior walls of this drum.

Collection and Draining

Once on the walls, gravity takes over. The honey runs down the sides and pools at the bottom of the drum. A valve or tap, often called a honey gate, is located at the base, allowing the beekeeper to easily drain the pure, collected honey into buckets for filtering and bottling.

Key Components of an Automatic Extractor

While the principle is simple, a few key components work together to make the process smooth and efficient.

The Electric Motor

This is the defining feature of an automatic extractor. Activated by a simple switch, the motor provides consistent and powerful rotation without any manual effort, saving immense time and energy.

The Frame Basket

Inside the drum is a cage or basket specifically designed to hold the uncapped honey frames securely. Some models are tangential, where frames face outward one side at a time and must be flipped. Others are radial, where frames are arranged like spokes on a wheel, allowing both sides to be extracted simultaneously.

The Cylindrical Drum

This outer container serves two purposes: it safely contains the high-speed spinning frames and acts as the collection vessel for the extracted honey.

Understanding the Trade-offs: Automatic vs. Manual

The decision to use an automatic extractor comes down to balancing efficiency with cost and scale.

The Advantage of Speed and Volume

Automatic extractors are designed for larger production volumes. They can process more frames in a fraction of the time it would take to do so with a manual, hand-cranked model.

The Benefit of Reduced Labor

For any beekeeper with more than a few hives, the physical effort of hand-cranking can be exhausting. An automatic model completely removes this strenuous task from the honey harvesting process.

The Consideration of Cost and Power

The primary trade-offs are cost and the need for electricity. Automatic extractors are a significantly larger investment than their manual counterparts and require a power source, which can be a limitation for operations in remote areas.

Making the Right Choice for Your Goal

Selecting the right tool depends entirely on the scale and ambition of your beekeeping operation.

- If your primary focus is a small-scale hobby with 1-3 hives: The simplicity, lower cost, and portability of a manual extractor is often the most practical choice.

- If your primary focus is efficiency for a growing or large-scale operation: An automatic extractor is an essential investment that pays for itself in saved time and labor.

Ultimately, understanding how these machines leverage a simple force is the first step toward a more efficient and rewarding honey harvest.

Summary Table:

| Feature | Automatic Extractor | Manual Extractor |

|---|---|---|

| Power Source | Electric Motor | Hand Crank |

| Best For | Large-scale / Commercial Operations | Small-scale / Hobbyist Beekeepers |

| Key Advantage | High Speed & Labor Saving | Lower Cost & Portability |

| Primary Consideration | Higher Initial Investment & Requires Electricity | Physical Effort & Slower Processing |

Ready to Scale Your Honey Production? As a trusted supplier for commercial apiaries and distributors, HONESTBEE provides robust, high-capacity automatic honey extractors designed for durability and efficiency. Let our equipment help you maximize your harvest and minimize labor. Contact our wholesale team today to discuss your operation's needs and explore our full range of beekeeping supplies.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

People Also Ask

- What are the potential drawbacks of using a honey extractor? Key Risks and Investment Realities

- What issues are addressed by the industrial centrifugal Honey Extractor? Boost Yield and Protect Your Combs

- How does equipment disassembly contribute to the proper cleaning of a honey extractor? Ensure Maximum Hygiene

- What role does an industrial centrifugal honey extractor play? Boost Hive Yield and Harvesting Efficiency

- How are U-shaped wire welded components utilized in basketless radial honey extractors? Lightweight Stability

- What defines a commercial honey extractor? High-Efficiency Industrial Solutions for Large-Scale Beekeeping Operations

- How do industrial weighing scales and honey extraction machinery contribute to evaluating apiary performance?

- What is a drill-powered honey extractor? Boost Your Harvesting Efficiency Without the High Cost