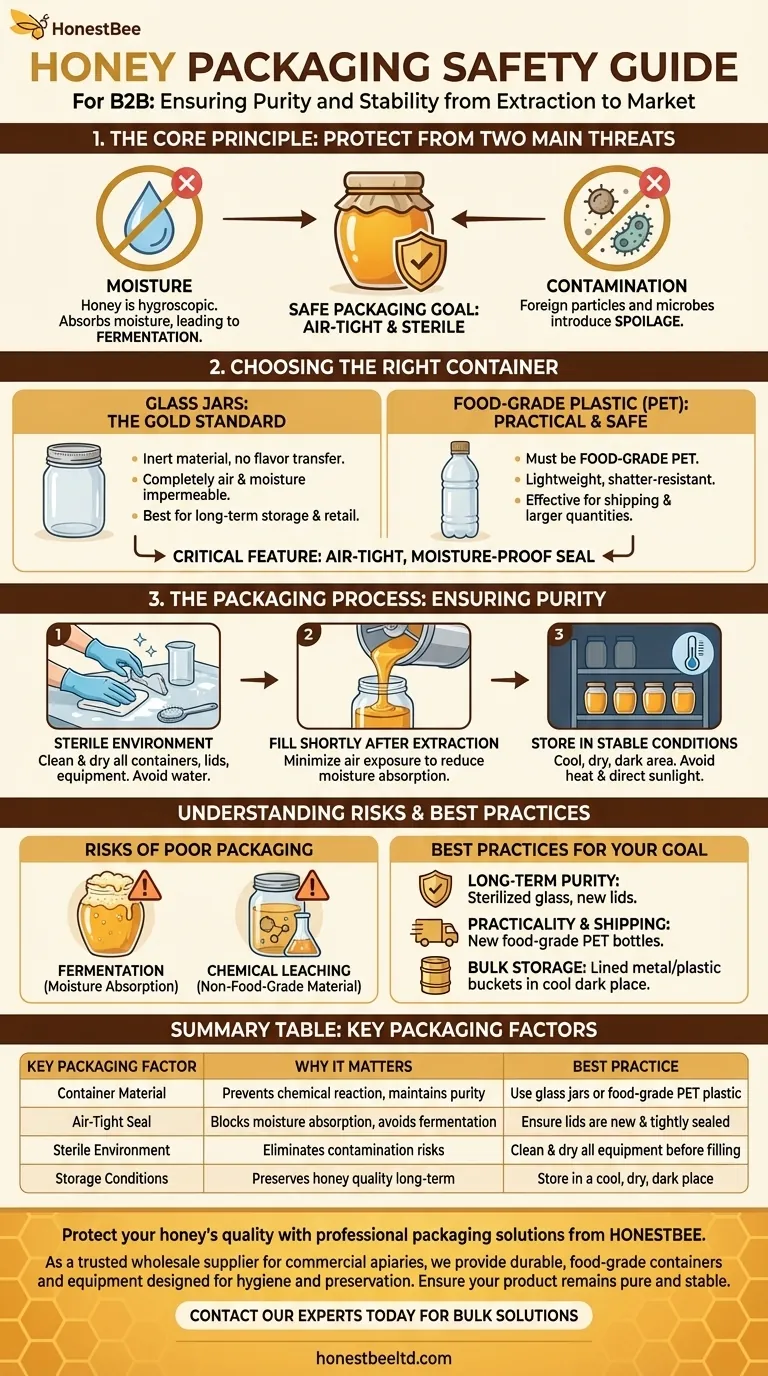

To package honey safely, you must use sterile, air-tight, food-grade containers and fill them in a clean environment shortly after extraction. The most common and effective materials are glass jars with screw-on lids or PET plastic bottles. The primary goal is to prevent the honey from absorbing moisture from the air and to avoid introducing any foreign particles that could cause spoilage.

The entire principle of safe honey packaging comes down to protecting it from two core threats: moisture and contamination. Honey is a naturally stable product, but a poor seal allows it to absorb water and ferment, while an unclean process can introduce matter that will spoil it.

The Foundation: Why Proper Packaging is Critical

Honey has remarkable natural preservative qualities due to its low water content and high sugar concentration, which create an environment where bacteria cannot thrive. However, this stability is not invincible and depends entirely on how it is handled and stored.

The Primary Threat: Moisture

Honey is hygroscopic, meaning it actively absorbs moisture from the surrounding air. If the container is not sealed properly, the honey's water content will rise.

Once the water content gets high enough, dormant natural yeasts present in the honey can become active and begin to ferment the sugars, spoiling the product.

The Secondary Threat: Contamination

Any foreign particles, dust, or organic matter introduced during the packaging process can compromise the honey's purity.

A sterile filling environment is essential to prevent unwanted microbes from entering the container, which could lead to spoilage or the growth of undesirable organic matter over time.

Choosing the Right Container

The material and quality of your container are your first line of defense. The single most important feature, regardless of material, is an air-tight, moisture-proof seal.

Glass Jars: The Gold Standard

Glass is inert, meaning it won't react with the honey or impart any flavors. It is also completely impermeable to air and moisture.

For long-term storage or retail presentation, glass jars with new, tight-fitting screw-on lids are considered the best option for maintaining purity.

Food-Grade Plastic: The Practical Alternative

If using plastic, it must be food-grade. PET (polyethylene terephthalate) plastic is a common, safe, and effective choice for honey.

Plastic offers the advantage of being lightweight and shatter-resistant, making it a practical option for shipping or larger quantities.

The Packaging Process: Ensuring Purity

How you transfer the honey into the final container is just as important as the container itself.

Sterility is Non-Negotiable

Before you begin, ensure your containers, lids, funnels, and any other equipment are thoroughly cleaned and completely dry. Even a small amount of water can upset the honey's natural balance.

Work on a clean surface and ensure your hands are clean to avoid introducing contaminants.

Fill Shortly After Extraction

Packaging your honey soon after it has been extracted and strained minimizes its exposure to open air. This reduces the opportunity for it to absorb ambient moisture or for dust and other particles to settle on its surface.

Store in a Stable Environment

Once packaged and sealed, honey should be stored in a cool, dry, and dark area. Heat can degrade the honey's delicate flavors and enzymes, while direct sunlight can diminish its quality over time.

Understanding the Trade-offs and Risks

Failing to adhere to these principles can lead to specific, preventable problems that will ruin your honey.

The Risk of Fermentation

This is the most common issue. If you notice your honey seems bubbly, has a foamy layer, or smells sour or alcoholic, it has likely fermented. This is a direct result of a poor seal that allowed the honey's water content to rise.

The Problem with Improper Materials

Using non-food-grade plastic can lead to chemicals leaching into the honey over time. Similarly, using metal containers that are not food-grade or lined can cause the honey to react with the metal, creating off-flavors.

Making the Right Choice for Your Goal

Your final decision should be based on your primary objective for the honey.

- If your primary focus is long-term preservation and purity: Use sterilized glass jars with new, tight-fitting metal lids.

- If your primary focus is practicality, cost, or shipping: Use new, food-grade PET plastic bottles with secure, moisture-proof seals.

- If your primary focus is bulk storage: Use large, food-grade plastic buckets or lined metal containers with well-sealing lids, kept in a cool and dark place.

By controlling for moisture and contamination at every step, you ensure your honey remains as pure and stable as the day it was harvested.

Summary Table:

| Key Packaging Factor | Why It Matters | Best Practice |

|---|---|---|

| Container Material | Prevents chemical reaction and maintains purity | Use glass jars or food-grade PET plastic |

| Air-Tight Seal | Blocks moisture absorption to avoid fermentation | Ensure lids are new and tightly sealed |

| Sterile Environment | Eliminates contamination risks | Clean and dry all equipment before filling |

| Storage Conditions | Preserves honey quality long-term | Store in a cool, dry, dark place |

Protect your honey's quality with professional packaging solutions from HONESTBEE.

As a trusted wholesale supplier for commercial apiaries and beekeeping equipment distributors, we provide durable, food-grade containers and equipment designed to meet the highest standards of hygiene and preservation. Ensure your product remains pure and stable from extraction to market—contact our experts today to discuss bulk packaging supplies tailored to your operation!

Visual Guide

Related Products

- Classic Drum Shaped Glass Honey Jar with Airtight Lid

- Hexagonal Glass Honey Jars with Metal Lug Caps Elegant Versatile Packaging

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- What are the advantages of using high-quality glass containers in the commercial packaging of honey? Boost Premium Value

- What are the technical advantages of using glass jars for honey? Master Commercial Packaging for Premium Purity

- Why is it important to store honey in airtight containers? Best Preservation Methods for Beekeepers

- Why are glass jars used for long-term honey preservation? Secure Chemical Stability & Analytical Accuracy

- Why is the use of standardized food-grade containers essential for honey? Secure Quality and Market Value