At a high level, modern bottle capping equipment is designed to handle three primary categories of caps based on their application method: threaded caps that are twisted on, press-on caps that are snapped into place, and insertion caps like corks that are pushed into the bottle opening. While many machines specialize in one type, others offer flexibility to handle variations within a category.

The critical insight is not just knowing the types of caps, but understanding that each cap type corresponds to a specific mechanical action—twisting, pressing, or inserting. Your choice of capping equipment is therefore a decision about matching the right machine action to your product, production speed, and budget.

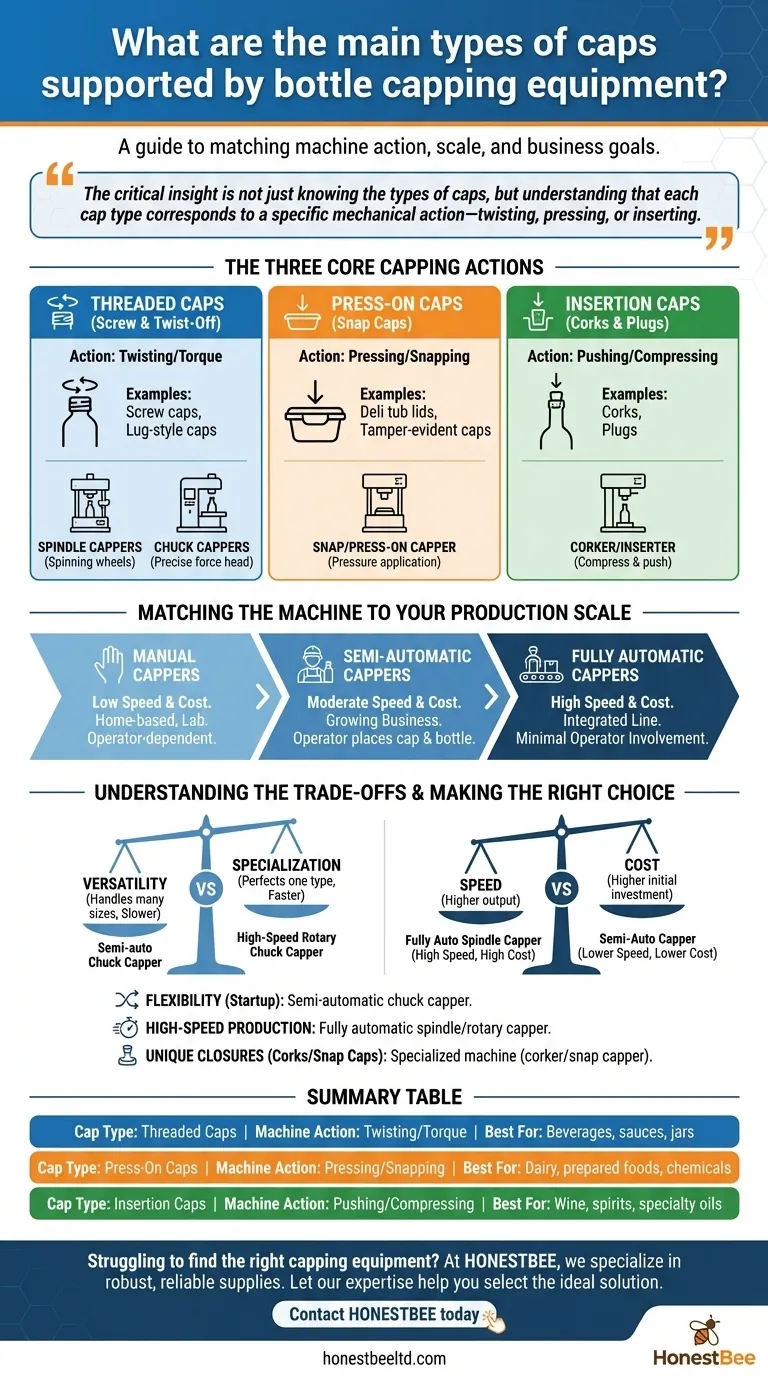

The Three Core Capping Actions

Instead of thinking in terms of dozens of specific lids, it's more effective to group them by the action the machine must perform. This simplifies the selection process significantly.

Threaded Caps (Screw & Twist-Off)

This is the most common category, encompassing everything from simple screw caps on water bottles to larger lug-style "twist-off" caps on glass jars. These require a machine that can apply consistent torque.

The two main technologies for this are spindle cappers, which use spinning wheels to tighten the cap as the container passes by, and chuck cappers, which place a capping head over the cap to twist it on with precise force.

Press-On Caps (Snap Caps)

This category includes caps that are snapped or pressed onto the container finish. These do not require any twisting motion.

Common examples include deli tub lids, overcaps, and some tamper-evident caps that feature a plastic ring that breaks away upon opening. The equipment for this is often called a "snap capper" or "press-on capper," which uses pressure to secure the lid.

Insertion Caps (Corks & Plugs)

This specialized category is for closures that are inserted into the neck of the bottle, creating a seal through compression.

The most familiar example is the cork used for wine bottles. Equipment for this action, often called a corker or inserter, is designed to compress the closure and push it into the container opening without damaging the product or bottle.

Matching the Machine to Your Production Scale

The right capping action must also be matched to your required output. The level of automation is the primary driver of speed and cost.

Manual Cappers

These are handheld or bench-top devices that are best for home-based businesses, lab work, or very small production runs. They are inexpensive but rely entirely on an operator for placement and activation.

Semi-Automatic Cappers

In a semi-automatic setup, an operator typically places the cap on the bottle and then positions it in the machine, which then performs the capping action. This offers a significant speed increase over manual methods and is ideal for growing businesses.

Fully Automatic Cappers

These machines are integrated into a production line. They automatically sort and place caps onto containers as they move along a conveyor before tightening, pressing, or inserting them. They are built for high-speed, continuous operation with minimal operator involvement.

Understanding the Trade-offs

Choosing capping equipment involves balancing competing priorities. Being aware of these trade-offs is crucial for making a sound investment.

Versatility vs. Specialization

A machine designed to do one thing perfectly, like a high-speed rotary chuck capper for a single beverage bottle, will always outperform a more versatile machine. A semi-automatic chuck capper might handle many different cap diameters, but it will be slower and require manual changeover between sizes.

Speed vs. Cost

The correlation is direct: higher speed demands more complex mechanics and automation, leading to a significantly higher initial cost. A fully automatic spindle capper can process hundreds of bottles per minute but costs multiples more than a semi-automatic machine that caps 10-20 per minute.

Changeover Complexity

For businesses running multiple products, the time it takes to adjust a machine for a different bottle or cap size is critical. Spindle cappers are often faster to adjust than chuck cappers, which may require swapping out entire chuck heads for different cap sizes.

Making the Right Choice for Your Goal

Your decision should be guided by your specific operational needs and future goals.

- If your primary focus is flexibility for a startup: A semi-automatic chuck capper offers a good balance of cost, speed, and the ability to handle various threaded cap sizes with simple change parts.

- If your primary focus is high-speed, dedicated production: A fully automatic spindle or rotary chuck capper designed for your specific cap and bottle is the most efficient long-term solution.

- If your primary focus is handling unique closures like corks or snap caps: You must invest in a specialized machine (a corker or snap capper) as the mechanical action is fundamentally different from a standard screw capper.

Ultimately, aligning the machine's core function with your product's specific closure is the first and most important step toward a reliable packaging line.

Summary Table:

| Cap Type | Common Examples | Machine Action | Best For |

|---|---|---|---|

| Threaded Caps | Screw caps, lug-style caps | Twisting/Torque | Beverages, sauces, jars |

| Press-On Caps | Deli tub lids, tamper-evident caps | Pressing/Snapping | Dairy, prepared foods, chemicals |

| Insertion Caps | Corks, plugs | Pushing/Compressing | Wine, spirits, specialty oils |

Struggling to find the right capping equipment for your production line?

At HONESTBEE, we specialize in supplying robust, reliable beekeeping supplies and equipment to commercial apiaries and distributors. We understand the critical need for precision and efficiency in packaging operations. Let our wholesale-focused expertise help you select the ideal capping solution to boost your productivity and protect your product integrity.

Contact HONESTBEE today for a consultation and discover how our equipment can streamline your packaging process.

Visual Guide

Related Products

- Semi Automatic Electric Bottle Capping Machine

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Semi Automatic Round Bottle Labeling Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- What is the purpose of a bottle capping machine? Boost Efficiency and Ensure Product Integrity

- Why is integrated packaging and labeling equipment important? Elevate Your Brand for Mainstream Retail Success

- What equipment is used for bottling honey cleanly and efficiently? Professional Filling Solutions for Every Scale

- Why is it advantageous for apiaries to be located near honey processing centers? Boost Quality and Market Reach

- How do modern honey packaging and sealing equipment enhance the commercial value of honey products? Boost Your ROI Today