A honey bottle labeling machine improves accuracy by replacing inconsistent human action with a system of precise, repeatable mechanics. Using advanced sensors for detection and automated applicators for placement, it ensures every label is placed in the exact same position, eliminating common manual errors like slanting, wrinkling, or incorrect positioning that can harm brand perception.

The core value of a labeling machine isn't just about achieving accuracy; it's about the systematic removal of human variability. This process guarantees unwavering consistency across thousands of units, which directly enhances product aesthetics, production efficiency, and overall marketability.

The Mechanics of Precision: How Machines Guarantee Accuracy

A labeling machine's accuracy comes from a perfectly synchronized, three-step automated process that leaves no room for error. Each step is controlled and executed identically for every single bottle.

Step 1: Sensor-Based Detection

The process begins when a sensor detects the precise moment a honey bottle arrives at the labeling station on the conveyor belt. This trigger ensures the labeling sequence starts at the exact right time, every time.

Step 2: Automated Label Dispensing

Once triggered, the machine automatically and smoothly peels a single label from its backing roll. This is performed with consistent speed and tension, preventing the tears or partial peels that can occur with manual handling.

Step 3: Controlled Mechanical Application

Finally, a mechanical applicator—such as a roller or a tamping pad—affixes the label to the bottle at a preset position and pressure. This controlled physical action ensures the label is perfectly straight, firmly attached, and free of bubbles or wrinkles.

Why Automation Outperforms Manual Labeling

The superiority of an automated system stems from its ability to perform a simple task flawlessly and continuously. This has a cascading positive effect on the entire production line.

Elimination of Human Error

Manual labeling is inherently prone to fatigue, distraction, and slight variations between workers and even between one hour and the next. Automation provides a fixed, repeatable process that is immune to these human factors, ensuring every product meets the same quality standard.

Consistent Product Aesthetics

Precise, uniform labeling presents a professional and trustworthy image on the retail shelf. This enhanced marketability and brand consistency is a direct, tangible result of the machine's precision.

Reduction in Material Waste

Inaccurate manual labeling often leads to discarded labels and, in some cases, wasted product. By getting it right the first time, a machine significantly reduces the material waste associated with labeling errors.

Understanding the Trade-offs and Considerations

While highly effective, integrating an automated labeling machine is a decision that requires careful thought about its operational demands and limitations.

Initial Capital Investment

Automated labeling machines represent a significant upfront cost compared to manual labor. This investment must be weighed against the long-term savings in labor costs, reduced waste, and increased throughput.

Calibration and Maintenance

To maintain their high accuracy, these machines require proper setup and regular maintenance. Incorrect calibration for different bottle sizes or label types is a primary cause of errors, so operator training is essential.

Limited Flexibility for Non-Standard Containers

A machine is typically optimized for specific bottle shapes and label dimensions. Frequent changes between different product lines or the use of highly irregular container shapes may require complex adjustments or entirely different equipment.

Making the Right Choice for Your Production Goals

Here is how to align the benefits of a labeling machine with your primary business objectives.

- If your primary focus is brand consistency and shelf appeal: The machine's greatest value is its ability to produce a perfectly uniform look for every single bottle, strengthening your brand identity.

- If your primary focus is increasing production volume: Automation delivers a dramatic boost in efficiency by combining high speed with the accuracy needed to prevent labeling from becoming a bottleneck.

- If your primary focus is reducing operational costs: A machine minimizes expensive human errors, reduces wasted labels, and provides a clear return on investment through lower long-term labor expenses.

Ultimately, investing in a labeling machine is a strategic decision to enforce quality control and scale your production with reliable efficiency.

Summary Table:

| Benefit | Key Takeaway |

|---|---|

| Accuracy | Eliminates slanting, wrinkling, and misplacement via sensor detection and mechanical application. |

| Consistency | Ensures every label is placed in the exact same position, bottle after bottle. |

| Efficiency | Increases production speed and reduces material waste from labeling errors. |

| Brand Image | Guarantees a professional, uniform look that enhances product marketability. |

Ready to scale your honey production with flawless, automated labeling?

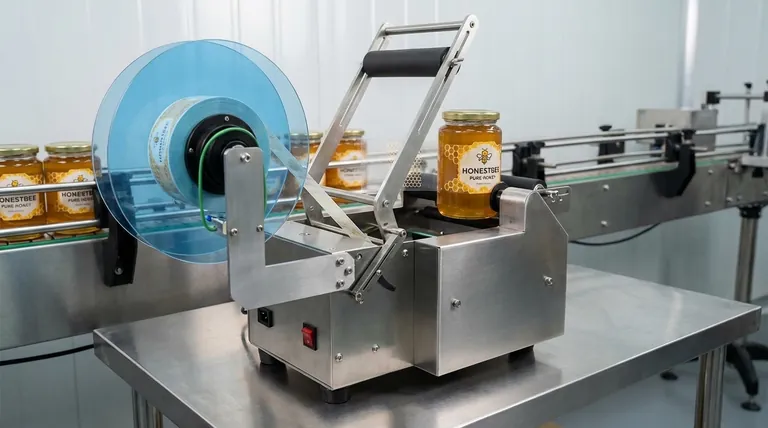

As HONESTBEE, a trusted wholesale supplier to commercial apiaries and beekeeping equipment distributors, we provide robust labeling solutions designed for high-volume, high-accuracy operations. Our machines are engineered to eliminate costly errors and ensure your brand looks perfect on every shelf.

Contact our experts today to find the right labeling machine to boost your efficiency and strengthen your brand.

Visual Guide

Related Products

- Semi Automatic Round Bottle Labeling Machine

- Automatic In-Line Round Bottle Labeling Machine

- 10L Stainless Steel Electric Honey Press Machine

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Automatic Honey Frame Uncapper Machine for Beekeeping

People Also Ask

- How does diverse labeling equipment for honey products enhance marketability? Boost Traceability & Premium Branding

- What impact do honey-themed cultural merchandise and high-quality packaging design have on the stingless bee industry?

- What are the advantages and disadvantages of manually applying honey labels? Expert Comparison for Your Brand

- What is the function of a labeling machine in honey packaging? Ensure Brand Consistency & Shelf Appeal

- What role do standardized glass jars and professional labeling play in the honey production value chain? Unlock Value

- What problems do industrial-grade packaging machines solve in bee product processing? Boost Efficiency and Hygiene

- Why are traceability labels and identification systems critical components of organic honey? Ensure Quality & Trust

- How do specialized honey packaging containers and labels enhance the commercial value? Boost Your Brand & Retail Price