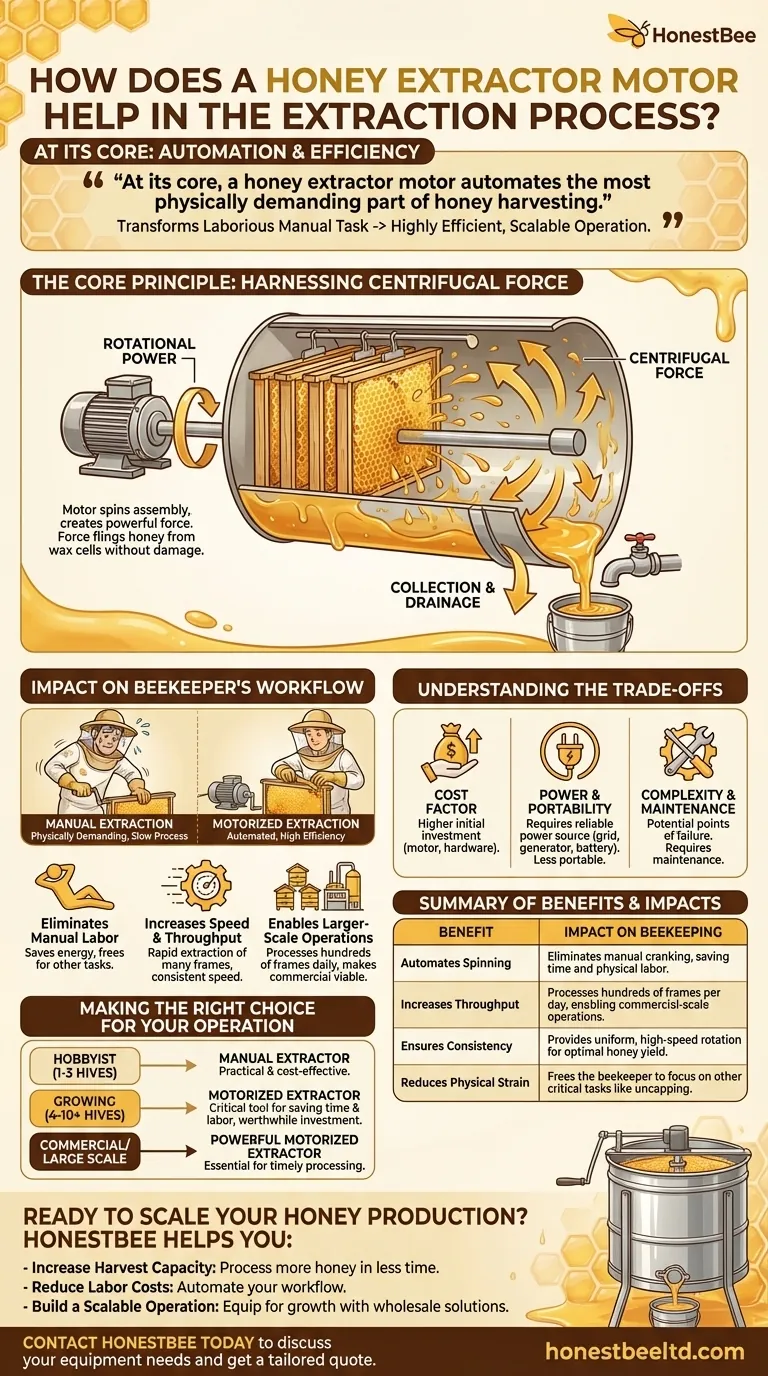

At its core, a honey extractor motor automates the most physically demanding part of honey harvesting. It provides consistent, high-speed rotational power to a drum holding the honeycombs. This automated spinning generates the centrifugal force required to pull honey from the wax cells without damaging the comb, dramatically improving the speed and efficiency of the entire process.

The fundamental value of a motor is its ability to transform honey extraction from a laborious, time-consuming manual task into a highly efficient, scalable, and less physically demanding operation.

The Core Principle: Harnessing Centrifugal Force

A motorized honey extractor is a practical application of physics. The motor's role is to create and sustain the specific force needed to separate honey from its comb.

From Rotational Power to Honey Flow

The motor turns a central shaft connected to a basket or drum that holds the uncapped honeycomb frames. As the motor spins this assembly, it creates powerful centrifugal force.

The Mechanics of Separation

This outward force acts on the honey within the open wax cells. It effectively flings the dense liquid honey away from the center of the extractor, pushing it out of the cells and onto the inner wall of the drum.

Collection and Drainage

Once separated from the comb, the honey runs down the extractor's interior walls. It then pools at the bottom of the tank, where it can be drained through a tap or gate valve for collection and processing.

The Practical Impact on the Beekeeper's Workflow

Replacing a hand crank with a motor fundamentally changes the extraction process, especially as the number of hives grows. It introduces a level of efficiency that manual power cannot match.

Eliminating Manual Labor

The most obvious benefit is the removal of the need to stand and continuously crank the extractor by hand. This saves an enormous amount of physical energy and frees the beekeeper to perform other tasks, such as uncapping the next batch of frames.

Increasing Speed and Throughput

A motor can spin the frames at a higher and more consistent speed than a person can. This allows for the rapid extraction of honey from a large number of frames in a fraction of the time required for manual extraction.

Enabling Larger-Scale Operations

For beekeepers with more than a few hives, a motor is not a luxury; it's a necessity. The efficiency gains allow for the processing of hundreds of frames in a single day, making larger-scale and commercial beekeeping operations viable.

Understanding the Trade-offs

While highly effective, a motorized system is not the default choice for every beekeeper. Understanding the downsides is key to making an informed decision.

The Cost Factor

Motorized extractors represent a significantly higher initial investment compared to their manual counterparts. The motor, controller, and associated hardware add to the overall cost of the unit.

Power and Portability

An electric motor requires a reliable power source. This can be a challenge in remote apiaries or off-grid locations, where a generator or battery system would be necessary. Manual extractors, by contrast, can be used anywhere.

Complexity and Maintenance

Adding a motor introduces another point of potential failure. While generally reliable, motors and their electronic controllers can require maintenance or repair, adding a layer of complexity not present in a simple, gear-driven hand crank.

Making the Right Choice for Your Operation

The decision to use a motorized extractor hinges entirely on the scale and goals of your beekeeping.

- If your primary focus is hobby beekeeping (1-3 hives): A manual extractor is often the most practical and cost-effective solution for a small annual harvest.

- If your primary focus is growing your operation (4-10+ hives): A motor becomes a critical tool for saving time and labor, representing a worthwhile investment in efficiency.

- If your primary focus is a commercial or large-scale sideline: A powerful, motorized extractor is essential equipment for processing your honey volume in a timely manner.

Ultimately, the motor is the engine that allows a beekeeper to scale their passion into a productive enterprise.

Summary Table:

| Benefit | Impact on Beekeeping |

|---|---|

| Automates Spinning | Eliminates manual cranking, saving time and physical labor. |

| Increases Throughput | Processes hundreds of frames per day, enabling commercial-scale operations. |

| Ensures Consistency | Provides uniform, high-speed rotation for optimal honey yield. |

| Reduces Physical Strain | Frees the beekeeper to focus on other critical tasks like uncapping. |

Ready to scale your honey production?

For commercial apiaries and beekeeping equipment distributors, a reliable motorized extractor is essential for profitability and growth. HONESTBEE supplies the durable, high-performance beekeeping equipment you need to operate efficiently at scale.

We help you:

- Increase Harvest Capacity: Process more honey in less time.

- Reduce Labor Costs: Automate the most demanding part of your workflow.

- Build a Scalable Operation: Equip your business for growth with wholesale-focused solutions.

Contact HONESTBEE today to discuss your equipment needs and get a quote tailored to your operation.

Visual Guide

Related Products

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- What are the key steps to follow when using a honey extractor? Expert Tips for a Perfect Harvest

- What should be considered when choosing a honey extraction method? Maximize Hive Health & Harvest Efficiency

- How long does an electric honey extractor take? Drastically Cut Your Harvest Time & Effort

- What are the features of a motorized honey extractor? Boost Efficiency and Precision in Your Honey Harvest

- How do automated honey extractors reduce physical strain for beekeepers? Boost Efficiency & Prevent Burnout