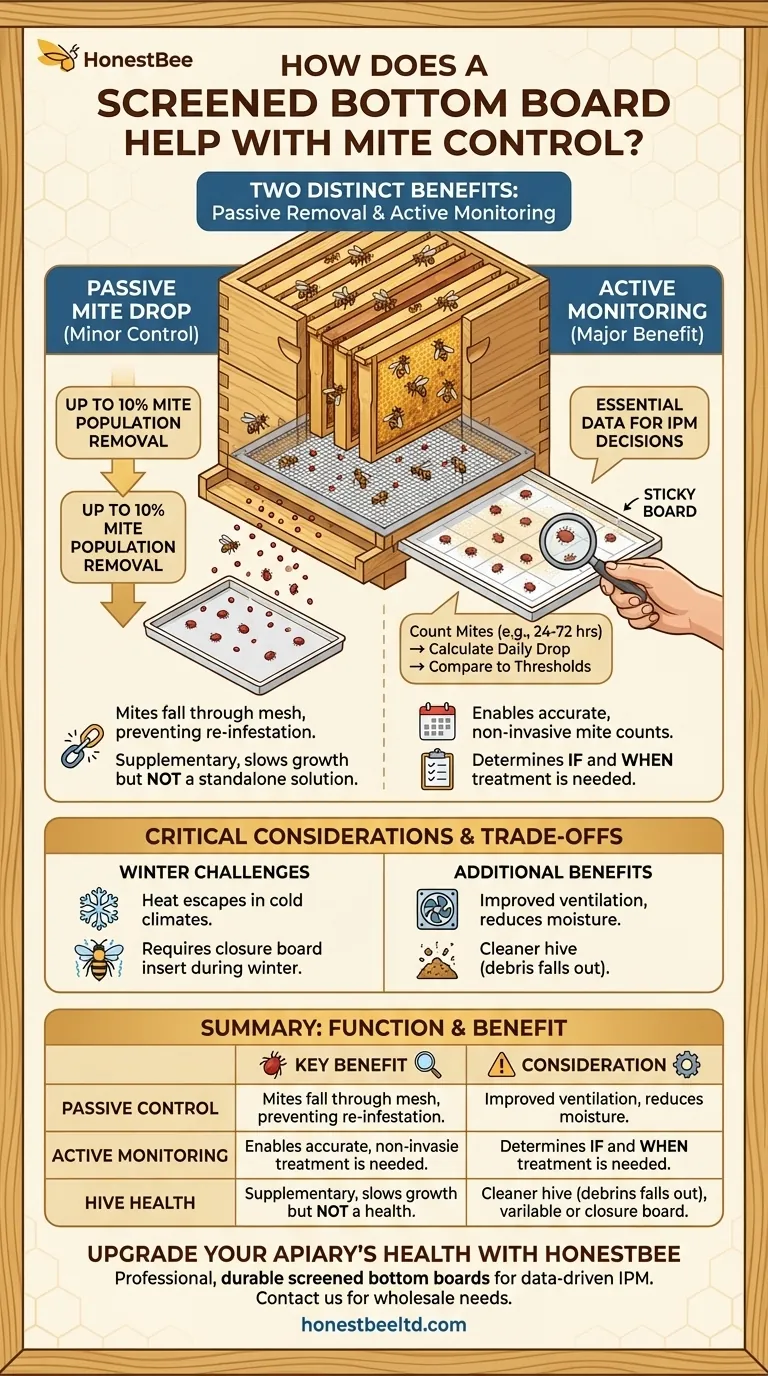

A screened bottom board contributes to mite control in two distinct ways. First, it allows a small percentage of Varroa mites that fall from bees to drop completely out of the hive, preventing them from re-infesting the colony. More critically, it serves as an essential tool for monitoring the hive's mite population, which is the cornerstone of any effective pest management strategy.

While the passive reduction of mites is a welcome benefit, the true power of a screened bottom board lies in its ability to provide you with the data needed to make informed treatment decisions. It is a monitoring tool first and a minor control method second.

The Mechanics of Mite Reduction

A screened bottom board replaces the traditional solid wood floor of a beehive with a sturdy section of #8 hardware cloth or mesh. This simple design change has a direct, albeit limited, impact on the resident mite population.

Passive Mite Drop

During natural grooming behaviors or movement within the hive, Varroa mites occasionally lose their grip and fall off their host bee.

With a solid bottom board, these mites can simply wait on the floor until another bee passes by, allowing them to climb aboard a new host and continue their lifecycle.

A screened bottom board creates an exit. Mites that fall will pass through the mesh and onto the ground below, effectively removing them from the hive. Studies suggest this passive drop can remove up to 10% of the mite population over time.

Interrupting the Mite Lifecycle

This passive removal, while small, helps disrupt the exponential growth of Varroa within the colony. Every mite that falls out is one less mite producing offspring within a brood cell.

However, this effect is supplementary. It slows the enemy but does not defeat it. It cannot stop a significant infestation on its own.

The True Power: Monitoring and Data

The most significant contribution of a screened bottom board to mite control is not passive removal, but active monitoring. It transforms the hive floor into a diagnostic tool.

Why Monitoring is Essential

Integrated Pest Management (IPM) is built on the principle of monitoring pest levels to determine when intervention is necessary. Treating blindly can lead to unnecessary chemical use and the development of resistant pests.

A screened bottom board allows for easy and non-invasive mite counts, giving you a clear picture of the infestation level inside your hive.

Conducting a Mite Count

To perform a count, a removable tray, often called a "sticky board," is inserted below the screen. This board is typically white and coated with a light layer of oil or petroleum jelly to trap any mites that fall.

After a set period (usually 24 or 72 hours), you can remove the board and count the number of trapped Varroa mites. This number gives you a direct sample of the "mite drop" in your colony.

Interpreting the Data

By dividing the number of mites by the number of days the board was in place, you get a daily mite drop average. Beekeepers use established thresholds to interpret this number.

If the count is below the threshold, no immediate action may be needed. If the count exceeds the threshold, it signals that the mite population is dangerously high and a treatment is required to save the colony.

Understanding the Trade-offs

While beneficial, a screened bottom board is not a perfect solution and comes with critical considerations. Misunderstanding its role is a common and costly mistake.

It Is Not a Standalone Treatment

The most dangerous pitfall is believing a screened bottom board alone can control Varroa mites. The passive mite drop is far too low to manage a healthy mite population's reproductive rate.

Relying solely on this equipment without regular monitoring and a plan for treatment will almost certainly lead to colony collapse.

The Challenge of Cold Climates

The ventilation that is beneficial in summer becomes a liability in winter. A screen allows significant heat to escape the hive.

The bee cluster must consume more honey and work harder to maintain its core temperature, leading to increased winter stress and potential starvation. Many beekeepers in cold regions slide in a closure board to convert the screen back to a solid bottom during the coldest months.

Additional Hive Benefits

Beyond mites, the screen provides excellent ventilation, which can reduce moisture buildup and help bees cure honey more efficiently. It also allows hive debris, like wax cappings and dead bees, to fall out, contributing to a cleaner internal environment.

Making the Right Choice for Your Apiary

The decision to use a screened bottom board depends on your climate and management philosophy.

- If your primary focus is proactive mite management: Use a screened board for its invaluable monitoring capabilities, but be prepared to close it off with an insert during winter in colder climates.

- If your primary focus is simplicity in a cold climate: A solid bottom board may retain more heat, but you must commit to other monitoring methods, such as an alcohol wash, to track mite levels.

- If your primary focus is reducing chemical use: A screened bottom board is an essential IPM tool, enabling you to treat only when absolutely necessary based on hard data from your mite counts.

Ultimately, a screened bottom board empowers you to make data-driven decisions, transforming you from a reactive keeper into a proactive hive manager.

Summary Table:

| Function | Key Benefit | Important Consideration |

|---|---|---|

| Passive Mite Control | Removes up to 10% of mites via natural drop. | Not a standalone treatment; effect is limited. |

| Active Mite Monitoring | Enables data-driven treatment decisions via sticky board counts. | Core function for Integrated Pest Management (IPM). |

| Hive Ventilation & Cleanliness | Reduces moisture and allows debris to fall out. | Can cause heat loss in winter; may require a closure board. |

Upgrade your apiary's health with professional beekeeping equipment from HONESTBEE.

Effective Varroa mite management starts with the right tools. As a trusted wholesale supplier for commercial apiaries and beekeeping equipment distributors, HONESTBEE provides durable, well-designed screened bottom boards and other essential supplies to support your IPM strategy.

Let us help you make data-driven decisions to protect your colonies and boost your productivity. Contact our team today to discuss your wholesale needs and discover the HONESTBEE difference.

Visual Guide

Related Products

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- HONESTBEE Wooden Bee Escape Board with Triangle Mesh Design for Beekeeping

- Boardman Entrance Bee Feeder Durable Galvanized Steel and Wood Construction for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

People Also Ask

- What is a screened bottom board and what are its uses? Enhance Hive Ventilation & Varroa Control

- How does a screened bottom board assist with temperature control and pest management? A Key Tool for Modern Beekeeping

- How should the screened bottom board be used throughout the year? A Guide for Healthy Hives

- What is the primary function of a screened bottom board on a beehive? Enhance Hive Ventilation & Pest Control

- What are the benefits of using wire mesh for a beehive floor? Boost Ventilation & Varroa Mite Control