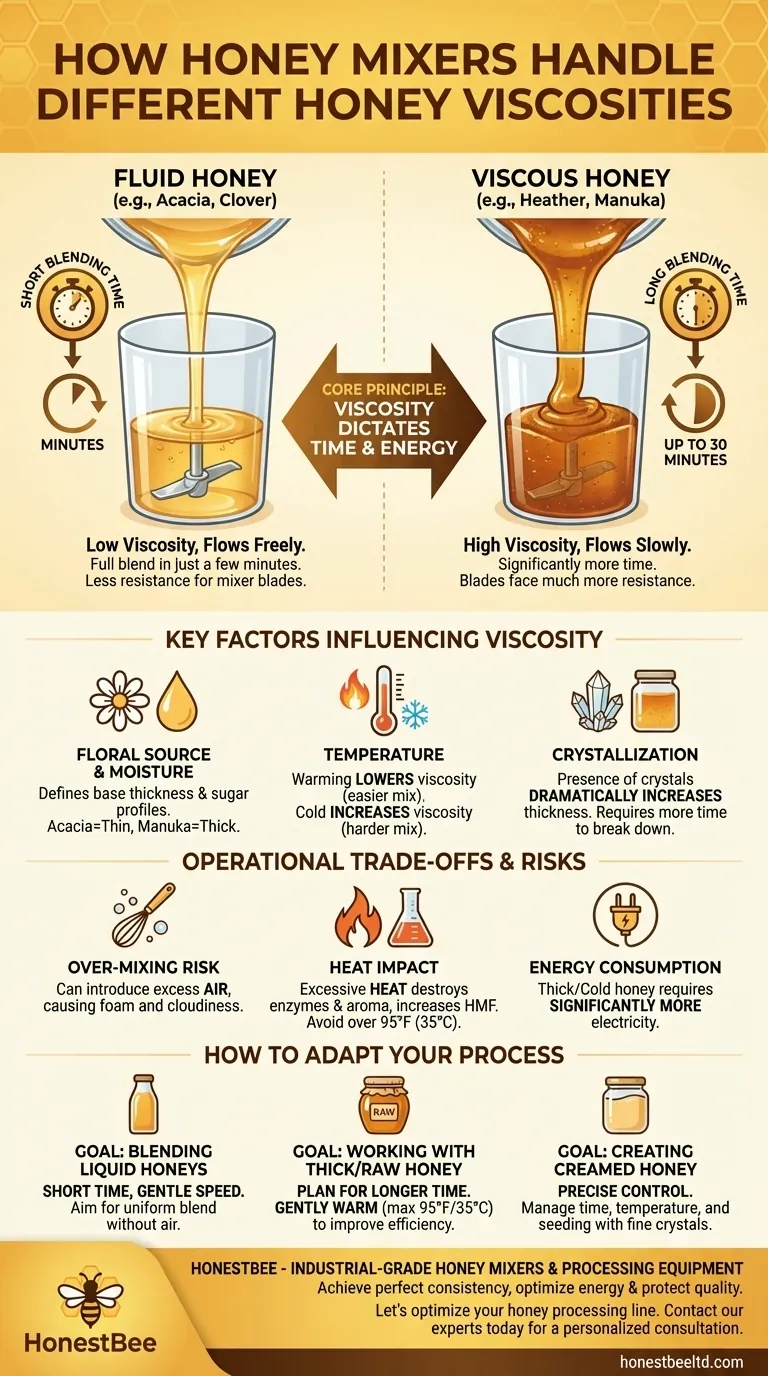

The short answer is a honey mixer adapts to different types of honey primarily by adjusting the blending time. Highly fluid honeys, like acacia or clover, can be fully blended in just a few minutes. Thicker, more viscous honeys, such as heather or manuka, require significantly more time—potentially up to 30 minutes—to achieve a uniform consistency.

The effectiveness of a honey mixer isn't just about the machine's power, but about understanding the properties of the honey itself. The key variable is viscosity, which dictates the time and energy required to achieve a smooth, consistent product.

The Core Principle: Honey Viscosity

The single most important factor determining how a honey mixer performs is the honey's viscosity, or its resistance to flow.

What is Viscosity?

Think of the difference between pouring water and pouring molasses. Water has low viscosity and flows freely, while molasses has high viscosity and flows slowly. Honey's viscosity can vary dramatically based on several factors.

Why Blending Time Varies

A mixer's blades must overcome the honey's internal resistance. For a low-viscosity (thin) honey, the blades move easily, creating a uniform blend quickly. For a high-viscosity (thick) honey, the blades face much more resistance, requiring a longer processing time to ensure all parts of the batch are thoroughly mixed.

Key Factors Influencing Honey's Viscosity

To master your mixing process, you must understand what makes honey thick or thin.

Floral Source and Moisture Content

The nectar source fundamentally defines the honey. Different floral nectars have unique sugar profiles (fructose-to-glucose ratios) and natural moisture content, directly impacting thickness. For example, Tupelo honey is famously thin, while buckwheat honey is typically much thicker.

Temperature

Temperature is the most effective tool for managing viscosity. Gently warming honey significantly lowers its viscosity, making it easier and faster to mix. A cold honey taken from storage will be extremely thick and difficult to work with.

Crystallization

The presence of sugar crystals dramatically increases honey's thickness. If you are working with raw, partially crystallized honey, the mixer's job is not just to blend but also to break down these crystals, which requires more time and energy. This principle is also used intentionally to produce finely textured creamed honey.

Understanding the Operational Trade-offs

Simply running the mixer longer isn't always the best solution. You must be aware of the potential consequences.

The Risk of Over-Mixing

Mixing for too long, especially at high speeds, can introduce excess air into the honey. This can lead to unwanted foam and a cloudy appearance in the final product.

The Impact of Heat

While warming honey makes mixing easier, excessive heat is detrimental. Overheating can destroy the delicate enzymes and aromatic compounds that define high-quality honey, and can also increase HMF (hydroxymethylfurfural) levels, a key indicator of heat damage.

Energy Consumption

A direct relationship exists between viscosity, time, and energy. Blending thick, cold, or crystallized honey will take longer and consume significantly more electricity than blending a warm, fluid honey.

How to Adapt Your Process

Your approach should change based on your specific goal and the type of honey you are working with.

- If your primary focus is blending liquid honeys for consistency: Your mixing time will be short. Aim for a gentle speed to achieve a uniform blend without incorporating air.

- If your primary focus is working with thick or raw honey: Plan for longer mixing times and consider gently warming the honey to a maximum of 95°F (35°C) to reduce viscosity and improve efficiency.

- If your primary focus is creating creamed honey: Your process involves intentionally controlling crystallization. This requires precise management of time, temperature, and seeding with fine honey crystals.

By understanding the properties of your honey, you transform the mixer from a simple tool into a precise instrument for achieving your desired outcome.

Summary Table:

| Factor | Effect on Viscosity | Impact on Mixing |

|---|---|---|

| Floral Source | Defines base thickness (e.g., Acacia=thin, Manuka=thick). | Dictates required blending time. |

| Temperature | Warming lowers viscosity; cooling increases it. | Warmer honey mixes faster and with less energy. |

| Crystallization | Presence of crystals dramatically increases thickness. | Requires more time/energy to break down crystals. |

Struggling with inconsistent honey blends or inefficient mixing times?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with industrial-grade honey mixers and processing equipment designed to handle the full spectrum of honey viscosities. Our solutions help you:

- Achieve perfect consistency across all your honey batches, from delicate acacia to thick manuka.

- Optimize your energy consumption and processing time with equipment built for efficiency.

- Protect honey quality by enabling gentle, controlled blending that avoids overheating and air incorporation.

Let's optimize your honey processing line. Contact our experts today for a personalized consultation on the right equipment for your specific honey types and production goals.

Visual Guide

Related Products

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What is the purpose of industrial-grade mixing and standardization equipment? Ensure Honey Consistency and Quality

- Why is specialized honey emulsification or stirring equipment utilized to produce cream honey? Elevate Your Honey Value

- What is the function of a temperature-controlled stirring device for inverted sugar syrup? Safe Bee Feed Preparation

- What are the key indicators for evaluating the efficiency of low-power mixing equipment using a tachometer? Maximize Torque

- What is the significance of honey homogenization? Elevate Commercial Honey Quality and Brand Consistency

- Why is thorough mechanical stirring and homogenization emphasized in honey processing? Ensure Sample Accuracy

- What is the necessity of combining large homogenization tanks with industrial mechanical stirrers in honey production?

- How does the honey mixer heat and melt crystallized honey? Master Indirect Heating for Quality Results