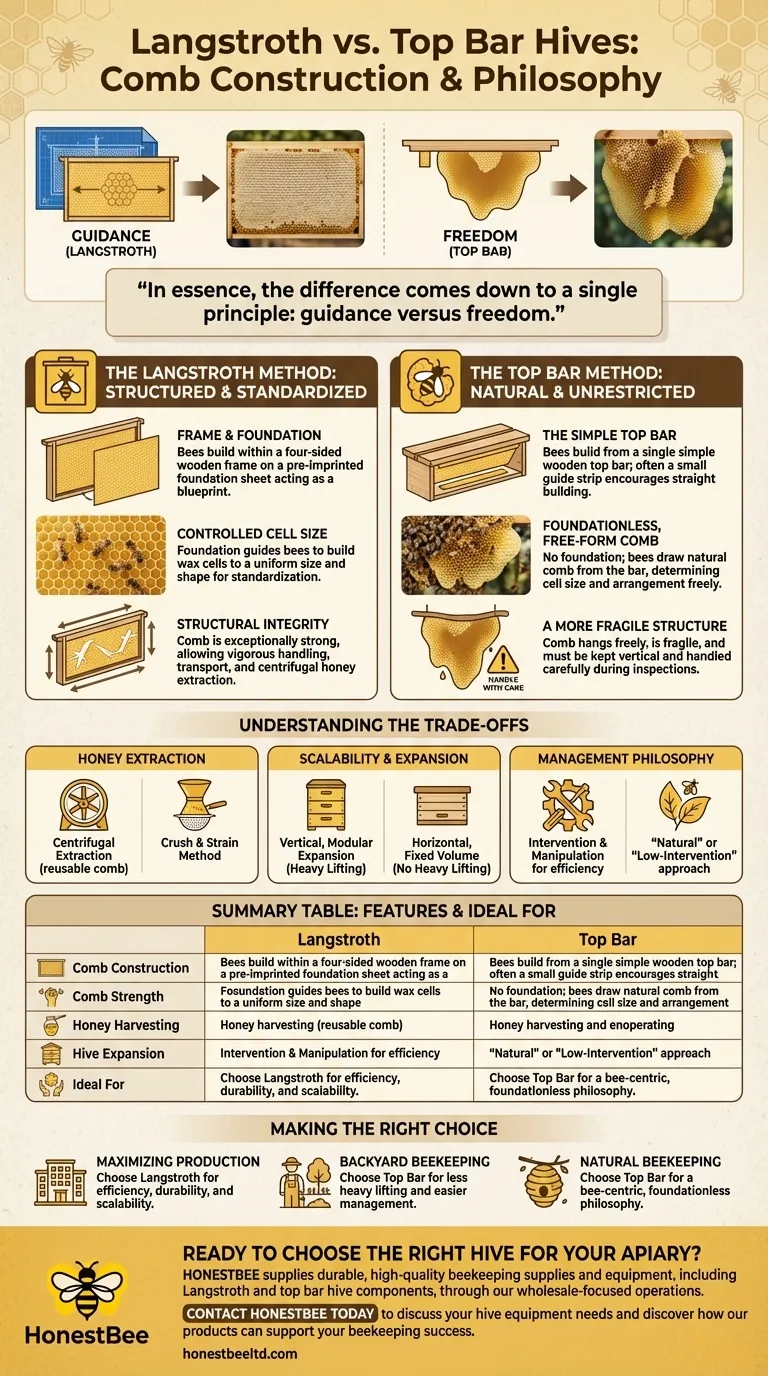

In essence, the difference comes down to a single principle: guidance versus freedom. A Langstroth hive uses frames with pre-imprinted foundation sheets to guide and control how bees build their comb. In contrast, a top bar hive provides only a simple wooden bar, allowing the bees to construct their comb naturally without a rigid structure.

The choice between a Langstroth and a top bar hive is not just a technical one; it reflects a fundamental difference in beekeeping philosophy. You are choosing between a highly structured, scalable system and a more natural, low-intervention approach.

The Langstroth Method: Structured and Standardized

The Langstroth hive is the most common design in modern beekeeping, engineered for efficiency and control. Its method of comb construction is central to its success.

The Role of the Frame and Foundation

In a Langstroth hive, bees build their comb inside a four-sided wooden frame. Within this frame sits a sheet of foundation, typically made of beeswax or plastic, which has been pre-imprinted with the hexagonal shape of honeycomb cells.

Controlled Cell Size

This foundation sheet acts as a blueprint. The bees use the imprinted hexagons as a guide, building out their wax cells to a uniform size and shape. This standardization is a key feature of the Langstroth system.

Structural Integrity

Because the comb is built within and attached to a four-sided frame, it is exceptionally strong and stable. This allows beekeepers to handle frames vigorously, transport hives, and use centrifugal extractors for honey harvesting without damaging the comb.

The Top Bar Method: Natural and Unrestricted

The top bar hive (TBH) represents a simpler, more "bee-centric" approach. Its design promotes a comb-building process that mirrors how bees build in the wild.

The Simple Top Bar

A TBH consists of a single, long horizontal box. Instead of frames, it uses a series of simple wooden top bars that lay across the top of the hive body. Often, a small wooden guide or a strip of wax is placed along the bottom of the bar to encourage the bees to build straight down.

Foundationless, Free-Form Comb

There is no foundation in a top bar hive. The bees build their comb by drawing it down from the single point of contact on the top bar. This is called foundationless or natural comb.

The bees determine the size and arrangement of the cells themselves, creating a mix of smaller worker cells, larger drone cells, and honey storage cells as the colony sees fit.

A More Fragile Structure

Because the comb hangs freely and is only attached at the top, it is far more fragile than comb in a Langstroth frame. It must be handled carefully and kept vertical during inspections to prevent it from breaking off the bar.

Understanding the Trade-offs

The differences in comb construction have significant downstream effects on hive management, labor, and philosophy.

Honey Extraction

With durable Langstroth frames, honey can be extracted using a centrifuge, which spins the honey out while leaving the wax comb intact for the bees to reuse. With fragile top bar combs, honey is typically harvested by cutting the comb from the bar and then crushing and straining it to separate the wax from the honey.

Scalability and Expansion

Langstroth hives are modular and expand vertically. As a colony grows, the beekeeper adds more boxes ("supers") on top. This allows for nearly unlimited expansion but requires lifting heavy boxes that can weigh over 50 pounds.

Top bar hives are horizontal and have a fixed volume. The colony expands across the bars from one end of the hive to the other. This design eliminates heavy lifting, as the beekeeper only ever needs to lift one bar at a time.

Management Philosophy

The Langstroth system is designed for intervention and manipulation. Its interchangeable frames make it easy to split hives, rear queens, and maximize honey production.

The top bar hive is favored by those practicing "natural" or "low-intervention" beekeeping. The foundationless comb allows bees to regulate their own cell size, and the management style is generally more hands-off.

Making the Right Choice for Your Beekeeping Goals

Your choice of hive should be driven by what you want to achieve as a beekeeper.

- If your primary focus is maximizing honey production and commercial viability: The efficiency, durability, and scalability of the Langstroth hive make it the undisputed industry standard.

- If your primary focus is backyard beekeeping with less heavy lifting: The horizontal, single-box design of the top bar hive is an excellent choice that is easier on your back.

- If your primary focus is "natural" beekeeping that mimics a wild colony: The foundationless comb and bee-centric design of the top bar hive align perfectly with this philosophy.

Ultimately, understanding how comb is built in each hive empowers you to choose the system that best matches your personal goals and physical capabilities.

Summary Table:

| Feature | Langstroth Hive | Top Bar Hive |

|---|---|---|

| Comb Construction | Guided by frames & foundation sheets | Natural, foundationless, built from a top bar |

| Comb Strength | Very strong & stable | Fragile, must be handled carefully |

| Honey Harvesting | Centrifugal extraction (reusable comb) | Crush & strain method |

| Hive Expansion | Vertical (add boxes/supers) | Horizontal (fixed volume) |

| Ideal For | Maximizing honey production, scalability | Natural beekeeping, less heavy lifting |

Ready to choose the right hive for your apiary?

Whether you manage a commercial operation or supply distributors, the right equipment is key to efficiency and honey production. HONESTBEE supplies durable, high-quality beekeeping supplies and equipment, including Langstroth and top bar hive components, through our wholesale-focused operations.

Contact HONESTBEE today to discuss your hive equipment needs and discover how our products can support your beekeeping success.

Visual Guide

Related Products

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- Top Bar Beehive for Beekeeping Wholesales Kenya Top Bar Hive

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

People Also Ask

- What are the most popular types of hives besides the Langstroth? Top Bar & Horizontal Hives Explained

- How does the top bar hive help control varroa mites? A Natural Approach to Mite Management

- How does the design of a top bar hive benefit beekeepers? Ergonomic & Natural Beekeeping for Hobbyists

- What are the technical and maintenance characteristics of the Top Bar Hive in commercial beekeeping? Key Insights

- What are the box management requirements for a top bar hive vs. Langstroth? Choose Your Hive Strategy