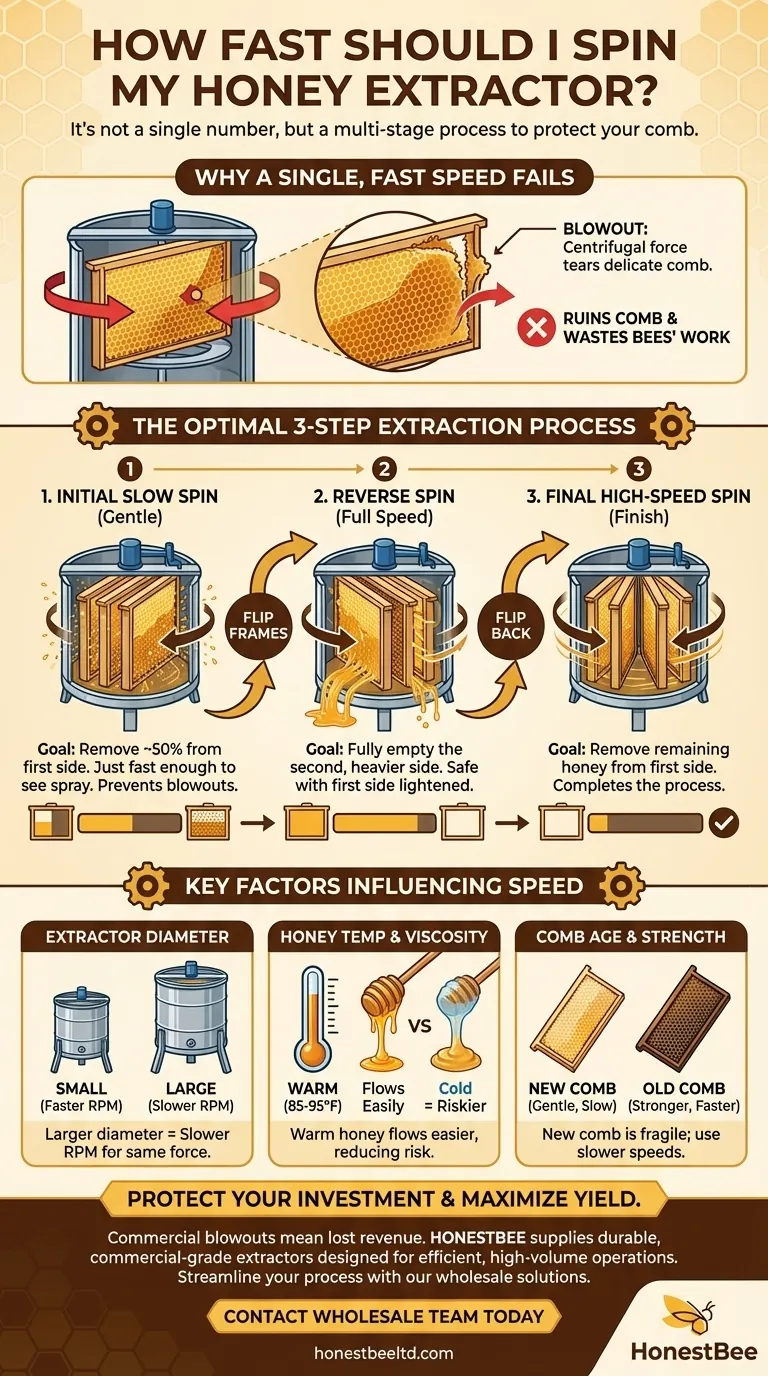

The ideal speed for your honey extractor is not a single number, but a multi-stage process. You begin with a very slow speed to partially empty the first side of the frames, then increase the speed in subsequent steps. Starting too fast will destroy your delicate wax combs.

The core principle of honey extraction is to balance centrifugal force against comb integrity. You must use a gradual, three-step increase in speed to prevent the weight of the honey on one side from blowing out the wax foundation on the other.

Why a Single, Fast Speed Damages Your Comb

When a frame is full of honey, it is extremely heavy. The wax comb is strongest at its base, where it's attached to the foundation. Spinning it too fast initially creates a critical problem.

The Physics of a "Blowout"

The centrifugal force acts on the honey in the outer cells, pulling it out. However, that same force is pushing the entire inner side of the comb against the outer side.

The weight of the honey still trapped on the inner side can be enough to tear the delicate wax comb completely off its foundation, resulting in a "blowout." This ruins the comb, which the bees then have to waste significant time and resources rebuilding.

The Optimal Three-Step Extraction Process

To avoid damage and extract the most honey, you must lighten the load in stages. While the reference of 10 minutes per side is a reasonable duration for a full cycle, it's how you use that time that matters.

Step 1: The Initial Slow Spin

Your first spin should be slow and gentle. The goal is to remove about half the honey from the first side of the frames.

The ideal speed is just fast enough to see honey begin to spray against the extractor wall. This lightens the frame enough to prevent blowouts.

Step 2: The Full-Speed Reverse Spin

Once the first side is partially empty, flip the frames so the un-extracted, heavier side is now facing out.

You can now apply full speed. With the first side lightened, there is no risk of a blowout, and you can safely extract all the honey from this second side.

Step 3: The Final High-Speed Spin

Finally, flip the frames back to their original position. The first side, which was only partially emptied, is now facing out again.

You can run the extractor at full speed one last time to remove the remaining honey from this side, completing the process.

Key Factors That Influence Your Speed

"Slow" and "fast" are relative terms that depend on several critical factors. You must adjust your technique based on your specific situation.

Extractor Diameter

The larger the diameter of your extractor, the slower the RPM (Revolutions Per Minute) needs to be to generate the same force. A small 2-frame extractor must spin much faster than a large 30-frame extractor to achieve the same result.

Honey Temperature and Viscosity

Warm honey is crucial. Honey extracted at 85-95°F (29-35°C) is significantly less viscous and flows out of the cells easily. Cold, thick honey requires much more force and time to extract, dramatically increasing the risk of comb damage.

Comb Age and Strength

Newly drawn, light-colored comb is far more fragile than older, darker comb that has been used for several brood cycles. You must be much more gentle and use slower speeds when extracting from new comb.

Making the Right Choice for Your Goal

Your primary objective should always be to preserve your drawn comb, as it represents a massive energy investment from your bees.

- If your primary focus is preserving fragile, new comb: Start at an extremely slow speed for the first spin, perhaps for a longer duration, and ramp up speeds very cautiously.

- If your primary focus is extracting from strong, dark comb: You can be more aggressive with your speeds, but the three-step process is still essential for maximum efficiency and safety.

- If you are extracting in cool conditions: The best solution is to warm the honey supers in a heated room for 24-48 hours before extracting. If you cannot, you must use slower speeds for longer durations.

Ultimately, mastering your extractor involves learning to balance speed, time, and temperature to get the most honey without undoing your bees' hard work.

Summary Table:

| Step | Objective | Recommended Speed | Key Action |

|---|---|---|---|

| 1. Initial Spin | Partially empty first side (≈50% honey) | Very Slow (just enough to see honey spray) | Prevent comb blowout |

| 2. Reverse Spin | Fully empty the second, heavier side | Full Speed | Flip frames after Step 1 |

| 3. Final Spin | Remove remaining honey from first side | Full Speed | Flip frames back to original position |

Protect your investment and maximize your honey yield with the right equipment.

As a commercial beekeeper or distributor, comb blowouts mean lost productivity and revenue. HONESTBEE supplies durable, commercial-grade honey extractors and beekeeping equipment designed for high-volume operations like yours. Our wholesale-focused solutions help you implement this optimal extraction process efficiently and safely.

Let's discuss how our equipment can streamline your operation. Contact our wholesale team today for pricing and catalog.

Visual Guide

Related Products

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

- Commercial 48-Frame Stainless Steel Honey Extractor

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

People Also Ask

- What type of honey extractor is best? Maximize Your Harvest Efficiency with the Right Choice

- What are the key stages of honey extraction? A Complete Guide for Beekeepers

- How long does it take to extract honey with an extractor? Plan Your Harvest for Maximum Efficiency

- What tips can maximize honey extraction efficiency? Unlock Higher Yields and Purer Honey

- What are some tips for using a honey extractor effectively? Maximize Your Honey Yield and Protect Your Comb