In terms of material science, a polystyrene hive body does not rot, decay, or suffer from fungal growth like wood. Because of this inherent resistance to biological degradation, a well-cared-for polystyrene hive can easily last for decades, often significantly longer than its wooden counterparts under similar environmental conditions.

The core takeaway is that while polystyrene as a material is exceptionally long-lasting, the practical lifespan of the hive is determined not by decay, but by your management practices. Its vulnerability to physical damage and UV light are the primary limiting factors, making careful handling the key to longevity.

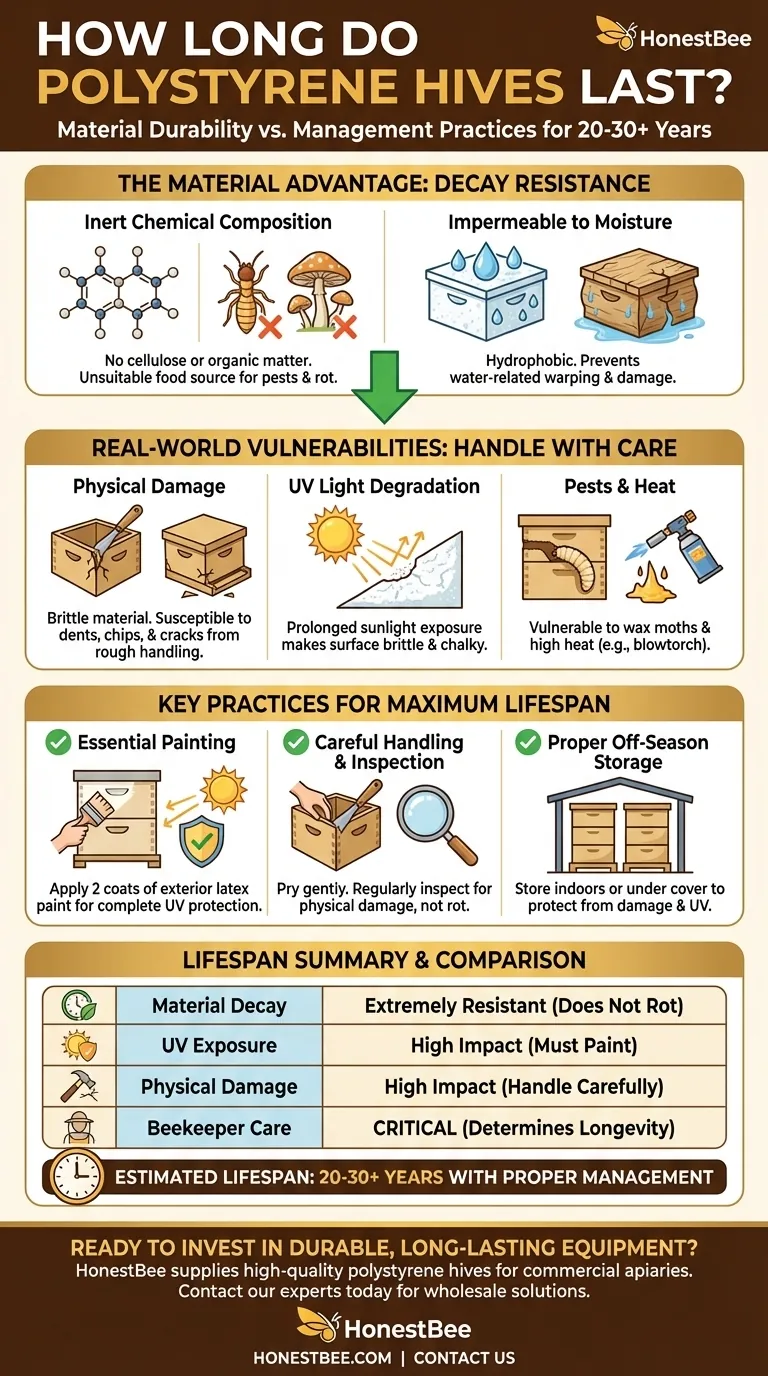

The Material Advantage: Why Polystyrene Resists Decay

Polystyrene hives, typically made from high-density expanded polystyrene (EPS), offer a fundamental advantage over traditional wood. Their longevity stems directly from their synthetic, non-organic structure.

Inert Chemical Composition

Polystyrene is a polymer, a form of plastic. It contains no cellulose or organic matter, making it an entirely unsuitable food source for the microorganisms, fungi, and insects (like termites) that cause wood to rot and break down.

Impermeable to Moisture

Unlike wood, which absorbs water, swells, and creates an environment for decay, polystyrene is hydrophobic. It does not absorb moisture, preventing the water-related damage and warping that shortens the life of wooden hive components over time.

Understanding the Real-World Vulnerabilities

While resistant to rot, a polystyrene hive is not indestructible. Its lifespan is ultimately dictated by factors that have little effect on wood.

Susceptibility to Physical Damage

This is the most significant factor. High-density polystyrene is rigid but brittle. Careless use of a hive tool to pry boxes apart can easily gouge, dent, or chip the edges. Dropping a box can cause cracks or crush corners, compromising its structure.

UV Light Degradation

Prolonged exposure to direct sunlight will slowly degrade the outer surface of unpainted polystyrene. The UV radiation makes the material brittle and chalky over many years, eventually leading to structural failure.

Vulnerability to Pests and Heat

While termites won't eat it, wax moths can burrow into the walls to pupate, creating a network of tunnels. Mice can also chew through the material to access the hive during winter. Furthermore, the heat from a blowtorch, often used to sterilize wooden equipment, will instantly melt polystyrene.

How Management Practices Determine Lifespan

A beekeeper's habits are the single most important variable in determining how long a poly hive will last. A few key practices can extend its useful life by decades.

The Critical Role of Painting

Applying two coats of a high-quality, light-colored exterior latex paint is not optional; it is essential. This paint layer serves as a complete UV block, protecting the polystyrene from sun degradation and dramatically extending its service life.

Careful Handling and Inspection

Learn to use your hive tool gently. Pry at the corners where the material is strongest or use a frame-lifter tool that minimizes pressure on the box edges. Regular inspections are less about rot and more about looking for physical damage or signs of pests.

Proper Off-Season Storage

When hive bodies are not in use, storing them indoors or under a solid cover is crucial. This protects them from accidental physical damage and unnecessary UV exposure, preserving them for the next season.

Making the Right Choice for Your Apiary

Choosing between polystyrene and wood involves weighing insulation and weight against a different type of required maintenance.

- If your primary focus is maximum forgiveness for rough handling: A traditional wooden hive may be a better choice, as it can withstand more aggressive prying and physical impacts.

- If your primary focus is longevity with consistent care: A properly painted and carefully handled polystyrene hive is an excellent long-term investment that can easily last 20-30 years or more.

- If your primary focus is insulation, winter survival, and light weight: The benefits of polystyrene are significant, and its lifespan is more than sufficient as long as you adapt your handling techniques.

Ultimately, the lifespan of a polystyrene hive is less about the material's clock and more about the beekeeper's hand.

Summary Table:

| Factor | Impact on Polystyrene Hive Lifespan |

|---|---|

| Material Decay | Extremely resistant; does not rot, unlike wood. |

| UV Exposure | High impact; causes degradation unless painted. |

| Physical Damage | High impact; brittle material can chip or crack. |

| Beekeeper Care | Critical; careful handling and painting are key. |

| Estimated Lifespan | 20-30+ years with proper management. |

Ready to invest in durable, long-lasting beekeeping equipment?

At HONESTBEE, we supply high-quality polystyrene hives and beekeeping supplies to commercial apiaries and distributors. Our products are designed for superior insulation and longevity, helping your operation thrive season after season.

Contact our experts today to discuss your wholesale needs and discover how our equipment can benefit your business. Let's build a more resilient apiary together.

Get in touch with HONESTBEE now!

Visual Guide

Related Products

- Professional Insulated Plastic Bee Hives

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Insulated Winter Hive Wrap for Beekeeping

People Also Ask

- How do high-performance insulated beehive materials affect pollination efficiency? Boost Yield in Temperate Climates

- What is a key advantage of Expanded Polystyrene (EPS) bee hives regarding maintenance? Minimal Upkeep & Higher Yields

- Why are plastic and polystyrene materials used in beehives? Enhancing Insulation and Durability for Commercial Success

- In what ways do high-quality polystyrene hives facilitate the collection of diverse bee products beyond honey?

- What are the advantages of synthetic foam for beehives? Improve Humidity Control & Honey Quality

- Is polystyrene better than wood beehives? A Modern Choice for Healthier Bees & Easier Management

- What is the effect of polyurethane foam hives on bee energy consumption and honey production? Boost Yields by 30%!

- What are the advantages of using high-performance polystyrene beehives? Boost Colony Survival and Efficiency